Are you thinking about buying a bag-making machine from China? You might be worried about making expensive mistakes. A wrong decision can cost you time, money, and leave you with unusable equipment.

The most common traps for beginners are choosing the wrong model, falling for low prices, trusting unverified suppliers, ignoring after-sales service, and skipping the fine print in contracts. Avoiding these mistakes is key to a smart investment and successful production.

Buying your first bag-making machine from China can feel overwhelming. Many new buyers focus only on the price tag. They aften overlook bigger issues that can cause major problems later. For example, a cheap machine might not work with your specific film materials. A supplier might disappear after you pay them. These are real risks. But you can avoid them with the right knowledge. We have been in this business for over 7 years and have helped hundreds of clients like you. We want to share our experience to help you make a good choice.

This guide will walk you through the five most common traps. We will show you what to look out for. We will explain how to verify a supplier. And we will help you understand why technical details and after-sales support are just as important as the price. Our goal is to give you the confidence to buy the right machine for your business.

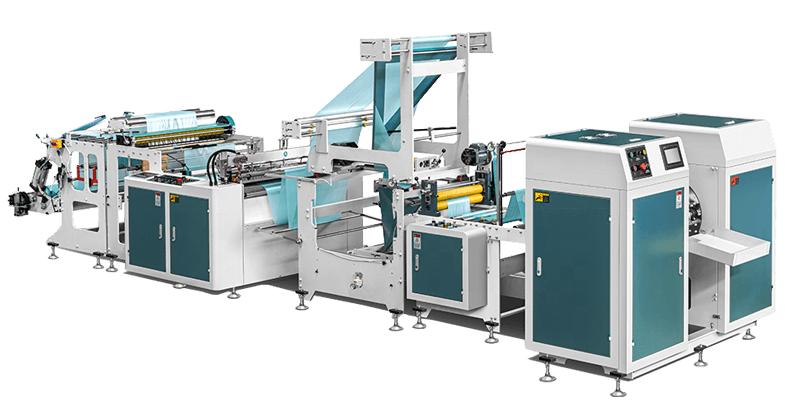

Choosing the Wrong Machine Model for Your Needs?

It’s easy to get excited and pick a machine that looks good. But what if it can't make the bags you actually need? This is a frequent and costly mistake.

The biggest mistake is not matching the machine to your specific needs. You must clearly define your product type, material, target speed, and automation level. Choosing a machine that doesn't align with these factors will lead to production failure.

Imagine you want to produce high-quality, tear-resistant courier bags for an e-commerce business. However, you buy a standard T-shirt bag machine because it was cheaper. The machine you bought cannot handle the thicker film required for courier bags. The seals are weak, and it lacks the necessary features for secure adhesive strips. You now own a machine that is completely wrong for your business model. This is why a detailed analysis of your needs is the first and most important step.

How to Define Your Requirements

Before you even talk to a supplier, you must have a clear picture of what you need. This prevents you from being sold a machine that a factory simply wants to get rid of. It puts you in control of the conversation.

Here are the core areas to define:

- Bag Type: Are you making T-shirt bags, garbage bags, food pouches, or heavy-duty industrial bags?

- Material: Will you use LDPE, HDPE, biodegradable PLA, or multi-layer laminated films?

- Production Capacity: How many bags do you need to produce per hour or per day?

- Automation: Do you need a fully automated line with PLC controls or is a semi-automatic machine enough to start?

Matching Machine Specs to Your Needs

Once you know what you need, you can evaluate a machine’s technical specifications. A trustworthy supplier will provide a detailed data sheet. At BagMec®, we provide this to every potential client.

Let's look at a simple comparison table to see how different needs require different machines.

| Factor | Your Requirement | Corresponding Machine Feature | Why It Matters |

|---|---|---|---|

| Bag Type | Laminated food pouches | Lamination Pouch Making Machine | Standard machines cannot seal multi-layer films properly, failing food safety standards. |

| Material | Biodegradable PLA film | Co-developed machine for PLA | PLA is brittle and requires special tension control, which our "Smart Tension Control" provides. |

| Speed | 2,500 courier bags/hour | High-speed, heavy-duty machine | A slower machine creates a production bottleneck and hurts your ability to fulfill orders. |

| Automation | Reduce labor costs | Fully automated system with PLC | This reduces human error, improves consistency, and allows for 24/7 operation. |

Case Study: Getting It Right

A US-based eco-brand wanted to produce 100% compostable shopping bags. They knew they needed to use PLA film. Instead of buying a standard HDPE bag machine, they partnered with us. We co-developed a machine optimized for their specific material. This partnership was a success because the client first understood their unique material need and then sought an expert who could meet it.

Falling for Unrealistically Low Prices?

Everyone loves a great deal. But when a price seems too good to be true, it almost always is, especially with industrial machinery.

Extremely low prices are a major red flag. They often mean the manufacturer used substandard parts, skipped vital safety features, or faked certifications. This results in frequent breakdowns, high repair costs, and a dangerous work environment.

A price that is 30-50% lower than the average market rate should make you suspicious, not excited. These low prices are achieved by cutting corners. A supplier might use cheap, untested steel for the machine frame, which can warp under stress. They might use second-hand or clone servo motors that consume more power and fail quickly. These hidden compromises will cost you far more in the long run than you "saved" on the initial purchase.

What's Hiding Behind a Rock-Bottom Price?

When you receive a quote that is significantly lower than others, you must ask "why?". The savings are coming from somewhere, and it's usually from critical components that affect performance, safety, and longevity.

Here are the most common areas where low-cost manufacturers cut corners:

- Materials: Using standard steel instead of high-carbon steel, which is weaker and less durable.

- Components: Employing cheap, non-branded electrical parts and motors instead of reliable, energy-efficient servo motors.

- Safety: Omitting essential safety features like emergency stop buttons, safety guards, and CE compliance to save money.

- Quality Control: Skipping the 72-hour stress test or precision alignment checks that we perform on every machine.

The Real Cost: A Price Comparison

Let's break down the difference between a typical low-price machine and a quality-built machine like ours at BagMec®.

| Component | Low-Price Machine | Quality BagMec® Machine | Long-Term Impact |

|---|---|---|---|

| Frame | Standard, thin steel | High-carbon steel frame | Cheap frames can vibrate and flex, causing poor seals and breakdowns. |

| Motors | No-name, high-power use | Energy-saving servo motors | Our motors reduce power consumption by up to 30%, saving you money every month. |

| Control System | Basic button panel | PLC control with touchscreen | An advanced PLC offers precise control, recipe storage, and remote diagnostics. |

| Certifications | None or fake | CE Compliance & ISO 9001 | Certified machines are proven to be safe and are built to a global quality standard. |

Think about it this way: a machine that costs $15,000 might seem expensive next to a $9,000 one. But if the cheap machine breaks down for two weeks, costing you $8,000 in lost revenue and repairs, you’ve already lost your initial "savings." True value comes from reliability and uptime, not just the initial price.

Trusting Fake or Unverified Suppliers?

The internet makes it easy to find dozens of suppliers in China. But it also makes it easy for fake companies to create a professional-looking website and disappear with your money.

Never send money to a supplier without verifying their identity. A legitimate manufacturer will have a real factory address, official business licenses, and quality certifications. Always ask for proof and, if possible, schedule a virtual tour.

This is one of the scariest traps for a new buyer. You find a supplier online with a great-looking website and very low prices. You have a few conversations over email, they send you a Proforma Invoice, and you wire the 30% down payment. Then, they stop responding. Their website goes down. You realize the address they gave you was fake. This happens more often than you think. Protecting yourself starts with a simple but non-negotiable rule: verify, verify, verify.

How to Spot a Fake Supplier

Fake suppliers often follow a pattern. Learning to recognize the red flags can save you from a major financial loss.

Common Red Flags:

- No Verifiable Address: They list a P.O. box or an address that doesn't show a factory on satellite maps.

- No Business License: They cannot provide a copy of their official Chinese business registration.

- Poor Communication: They avoid video calls and only communicate through text-based chat or email.

- Pressure for Payment: They push hard for a large, upfront payment via an untraceable method like Western Union.

- Generic Photos/Videos: The factory photos on their website look like stock images or are stolen from other companies.

A Step-by-Step Verification Checklist

At BagMec®, we encourage our clients to be thorough because we are proud of our operations and have nothing to hide. Here is what you should do to verify any supplier:

- Request their Business License: Ask for a copy of their business license and use a third-party service or a contact in China to verify it is active and legitimate.

- Ask for Certifications: Request copies of their ISO 9001 and CE certificates. Check the certificate numbers with the issuing bodies to ensure they are valid.

- Schedule a Live Video Call and Factory Tour: This is the best way to verify they are real. Ask them to walk you through their factory floor on a live video call. At BagMec®, we offer virtual tours to all potential clients. You can see our 12+ production lines and meet our team.

- Check for an International Presence: A real company will have export records and client cases. For example, we proudly share our benchmark cases, like the eight FFS machines we deployed for a German packaging supplier.

Ignoring the Importance of After-Sales Service?

Your relationship with a supplier doesn't end when the machine is delivered. In many ways, it's just beginning. What happens when you have a technical problem?

Ignoring after-sales service is a huge risk. A good supplier provides installation support, operator training, available spare parts, and ongoing technical help. Without this, a simple issue can shut down your entire production line for weeks.

Many first-time buyers are so focused on the machine's price that they forget to ask about the support structure behind it. Imagine your machine arrives, but the instruction manual is poorly translated and you can't set it up correctly. Or, a critical part fails three months later, and the supplier tells you it will take two months to ship a replacement. This is the reality when you choose a supplier with poor or non-existent after-sales service.

What Good After-Sales Service Includes

Excellent after-sales support is a key part of the value we provide at BagMec®. It's the difference between a simple transaction and a long-term partnership.

| Service Feature | Poor Supplier | A Great Partner (BagMec®) |

|---|---|---|

| Installation & Training | "Good luck" and a bad manual. | Optional on-site installation and comprehensive training services. |

| Technical Support | Slow email replies, no live support. | 24/7 technical team, IoT-enabled remote diagnostics to solve issues fast. |

| Spare Parts | Long wait times, no stock. | Key parts in stock, standard 45-day delivery (25 days for repeat clients). |

| Warranty | Vague or non-existent. | Clear, written warranty on all major components. |

Case Study: Solving the Support Challenge

We worked with Priya Kapoor, the founder of an e-commerce startup in India. Her previous machine supplier offered no technical support, leaving her team struggling with any minor issue. She chose us for her new courier bag machine specifically because of our support system. Our machines are IoT-enabled, meaning our engineers can remotely diagnose problems and guide her team through a fix over a video call. This feature—future-ready technology—is a core part of what we offer.

Critical Questions to Ask Every Supplier

Before you sign a contract, ask these direct questions about after-sales service:

- What does your warranty cover and for how long?

- Do you offer on-site installation and what is the cost?

- What is your process for providing technical support? Do you offer remote diagnostics?

- How quickly can you ship critical spare parts to my country?

- Is your technical documentation and support available in English?

Skipping the Contract Details and Technical Specs?

You have verified the supplier and agreed on a price. Now comes the paperwork. Rushing through the contract is the final trap that can undo all your hard work.

Never sign a contract without carefully reviewing every detail. The agreement must include precise technical specifications, a clear payment schedule, shipping terms (Incoterms), and detailed warranty information. This document is your only protection if something goes wrong.

A contract, or Proforma Invoice (PI), is more than just a formality. It is a legally binding document that outlines the exact obligations of both you and the supplier. A vague contract leaves room for misunderstandings and disputes. For instance, if the contract just says "T-Shirt Bag Machine" without specifying the speed, material thickness, or included accessories, the supplier can deliver the most basic model, and you would have no legal ground to complain.

Must-Have Elements in Your Purchase Contract

A professional supplier will provide a detailed contract without you having to ask. At BagMec®, our quotes, which are delivered within 48 hours, include all of these details. Ensure your contract clearly states:

- Full Machine Specifications:

- Model name and number.

- Production speed (e.g., 200 bags/minute).

- Compatible materials and thickness range (e.g., HDPE 10-50 microns).

- Maximum bag dimensions (width and length).

- Power requirements (voltage, phase, frequency).

- List of All Included Items:

- Tool kits, spare parts, and user manuals.

- Any optional units you paid for, like a logo embosser or die-cutter.

- Price, Payment, and Shipping Terms:

- Total price and currency (e.g., $17,500 USD).

- Payment schedule (e.g., 30% down, 70% before shipping).

- Shipping terms (e.g., FOB Shanghai, CIF New York). We offer EXW, FOB, CIF, and DDP.

- Warranty and Support Details:

- A clear statement of the warranty period and what it covers.

- A commitment to after-sales support procedures.

Why Technical Specs Are Your Best Friend

The technical specification sheet is arguably the most important part of your contract. It is the objective measure of the machine's performance. For example, our German client required 99% uptime for their FFS bag machines. This was achievable because their contract specified our patented "Smart Tension Control" technology and energy-saving servo motors. These are not just marketing terms; they are contractual performance guarantees.

Before you sign anything, take the Proforma Invoice and technical sheet to your team. Review every line item. If anything is unclear or missing, ask for a revision. A good supplier will be happy to provide clarity. A supplier who resists is a major red flag.

Conclusion

Buying a bag-making machine from China can be a fantastic move for your business. You can get great technology at a competitive price. But you must be careful. By avoiding these five common traps, you shift from being a hopeful buyer to a smart investor.