Buying a high-speed machine from China feels complicated. You might worry about quality, scams, or difficult communication. I will give you a clear, step-by-step guide to succeed.

To buy a high-speed T-shirt bag machine1 from China, you must define your production needs, find credible manufacturers, verify their history and certifications, negotiate the price and terms, manage shipping and customs, and plan for installation and after-sales support.

This process seems like a lot, but I will break it down for you. It all starts with understanding your specific needs. You need to know what materials you will use and your target output. Then, you can find a manufacturer that fits your criteria. I will show you how to check if a supplier is reliable. We will cover the entire journey, from your first inquiry to the machine running in your facility. We have been helping new buyers since 2017, so I know exactly what you need to feel confident in your purchase.

This guide gives you practical steps. First, we will define what a high-speed T-shirt bag machine is. Second, we will look at different types, like models with advanced servo motors that save energy. Third, I will provide real cost estimates. For example, our BagMec® T-Shirt Bag Making Machines range from $17,000 to $32,000. Finally, I will share tips for evaluating a manufacturer by checking their export history and market presence, much like other successful global suppliers. My goal is to remove all the guesswork for you.

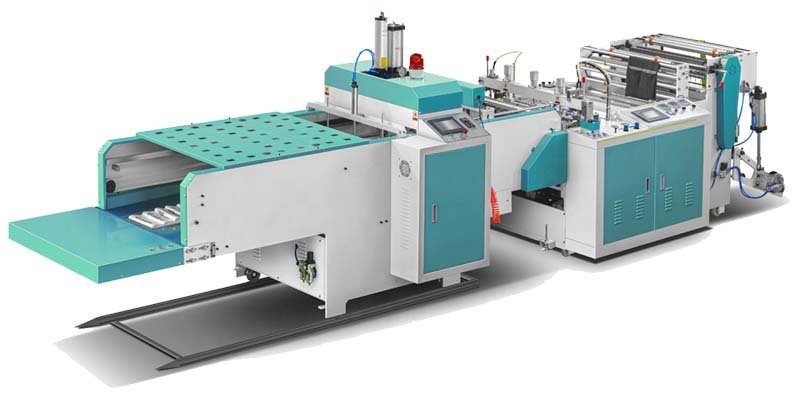

What Is a High-Speed T-shirt Bag Making Machine? Essential Basics for Beginners

So, what is this machine? Let's start with the basics. This will help you understand exactly what you are investing in for your business.

A high-speed T-shirt bag making machine is an automated system that converts plastic film rolls into finished shopping bags. It uses heat sealing and cutting to produce bags with built-in handles at a high rate, ready for retail or other uses.

The Inner Workings of the Machine

How It Works: A Step-by-Step Process

A T-shirt bag making machine follows a clear sequence to create bags. Understanding this helps you appreciate its engineering and identify potential issues.

- Unwinding: A large roll of plastic film (like HDPE or LDPE) is placed on an unwind stand. Our BagMec® machines feature a "Smart Tension Control" system here, which ensures the film feeds smoothly and consistently, preventing wrinkles or tears.

- Folding & Gusseting: The flat film is folded in half. A special device creates side gussets, which are the indented folds that allow the bag to expand and hold more volume.

- Sealing & Cutting: The folded film moves to the sealing station. A heated bar, called a sealing knife, presses down on the film. It simultaneously creates the bottom seal of one bag and the top edge of the next. It then cuts them apart.

- Handle Punching: A hydraulic or pneumatic punch cuts out the "T-shirt" style handles. This happens at very high speed and precision.

- Stacking: The finished bags are automatically collected and stacked in neat piles of a pre-set quantity, like 50 or 100 bags. This makes them easy to pack.

Key Components and Terminology

When you talk to manufacturers, you will hear these terms. Knowing them will help you have a more productive conversation.

| Term | What It Means | Why It's Important |

|---|---|---|

| PLC (Programmable Logic Controller) | The "brain" of the machine. It's a computer that controls all operations, from speed to bag length. | A good PLC (from brands like Siemens or Delta) means the machine is reliable and easy to program. All our machines use them. |

| Servo Motor | An advanced motor that allows for very precise control over movement and positioning. | Servo motors increase bag length accuracy, reduce plastic waste, and save up to 30% on energy. They are a key feature of our high-end models. |

| Photocell (Color Mark Sensor) | A sensor that reads printed marks on the film. | This is essential for making printed bags. It ensures the sealing and cutting happen in the right place relative to the printed design. |

| HDPE/LDPE Film | The raw material. HDPE is high-density polyethylene (crispy bags), and LDPE is low-density polyethylene (softer bags). | The machine must be designed to handle the specific film type you plan to use. Our machines are compatible with both, plus biodegradable PLA. |

| Sealing Knife | The heated bar that seals and cuts the plastic. | The quality of this knife determines the strength of your bag seals. We use high-quality steel with durable coatings. |

Which Type of Machine Should I Buy? Key Considerations for Choosing the Right Model

Not all T-shirt bag machines are created equal. Making the right choice is critical for your production efficiency and business growth. Let's look at the factors.

You should choose a machine based on four key things: the material you will use, your required production volume, the level of automation you need (semi vs. full), and any special features like multi-color printing or double-line production.

Matching a Machine to Your Business Needs

Full-Automatic vs. Semi-Automatic

This is one of the first decisions you will make. It directly impacts your investment, labor costs, and output. A fully automatic machine handles everything from unwinding to stacking. A semi-automatic one might require manual help for tasks like final packing.

| Feature | Semi-Automatic Machine | Fully Automatic Machine |

|---|---|---|

| Initial Cost | Lower (Good for tight budgets) | Higher (A larger investment) |

| Labor Needs | Requires more operator involvement | Runs with minimal supervision |

| Production Speed | Slower (e.g., 80-120 bags/min) | Faster (e.g., 150-250 bags/min) |

| Consistency | Can vary slightly with operator skill | Highly consistent, fewer errors |

| Best For | Startups, small businesses, or producing for a local market. | Established businesses, large-scale production, export markets. |

For most new buyers looking to scale, I recommend a fully automatic machine. The higher initial cost is often recovered quickly through lower labor costs and higher output.

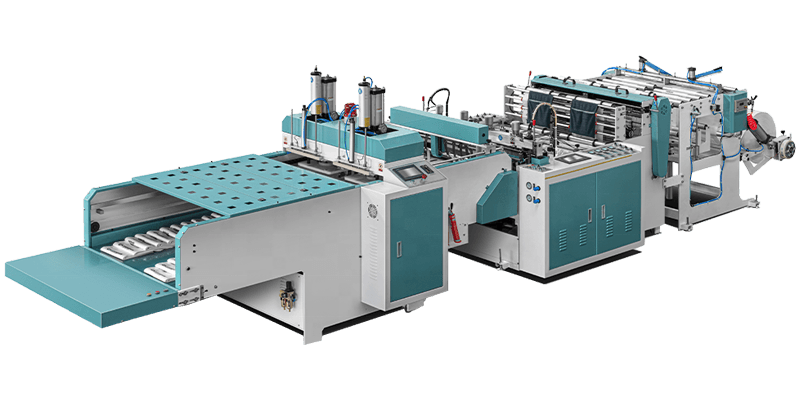

Single Production Line vs. Double Production Line

Once you choose full automation, you need to decide on production capacity.

- Single-Line Machine: Has one production lane. It processes one roll of film at a time. This is the standard choice for many businesses.

- Double-Line Machine: Has two parallel production lanes. It can process two smaller film rolls simultaneously, effectively doubling your output in the same amount of floor space.

When to choose a double-line machine?

Choose a double-line model if you have high-volume orders and want to maximize production efficiency. For example, our Indian logistics client chose a custom high-speed line to produce 2,500 courier bags per hour. While they make courier bags, the principle is the same for T-shirt bags. Higher output means a faster return on your investment.

Material Compatibility

Your machine must be optimized for the film you intend to use.

- Standard HDPE/LDPE: Nearly all machines are designed for this.

- Recycled Materials: If you plan to use recycled film, the machine needs a more robust heating element and tension control system, as recycled material can have inconsistent thickness.

- Biodegradable/Compostable Films (PLA): These materials are more sensitive to heat. They require a machine with very precise temperature control to avoid burning the film. We co-developed a machine for a US eco-brand specifically for their 100% compostable PLA bags.

Always tell your manufacturer exactly what material you will use. At BagMec®, we customize the machine's settings and components to match your specific film.

How Much Does a T-shirt Bag Making Machine Cost in China? Budget Planning Tips

Let's discuss the budget. A clear understanding of costs is essential for planning. It helps you avoid unexpected expenses down the road.

In China, a high-speed T-shirt bag making machine typically costs between $17,000 and $32,000. The final price is influenced by speed, automation, brand, material quality, and custom features like servo motors or printing units.

A Complete Budget Breakdown

Your total investment is more than just the price tag on the machine. Here is a more detailed look at what you should budget for.

Core Costs vs. Optional Add-ons

| Cost Component | Description | Estimated Cost (USD) | Is it Essential? |

|---|---|---|---|

| Base Machine | The standard, functional machine without extras. | $17,000 - $25,000 | Yes |

| Servo Motor Upgrade | Upgrades from a stepper motor for higher precision and energy savings. | +$2,000 - $5,000 | Highly Recommended |

| In-line Printer Unit | A unit to print logos or designs on the bags as they are made. | +$3,000 - $10,000+ (depending on colors) | Optional |

| Double-Line Configuration | To double the production output. | +$8,000 - $12,000 | Optional |

| Spare Parts Package | A 1-2 year supply of common wear parts (heating elements, blades). | +$500 - $2,000 | Highly Recommended |

Beyond the Machine: Other Expenses to Plan For

These are often called "hidden costs," but a good manufacturer will discuss them with you upfront.

- Shipping and Insurance (Freight): This depends on your location and the shipping term (e.g., FOB, CIF). From China to Europe or the Americas, this can be $1,500 - $4,000 for a single machine.

- Import Duties and Taxes: Every country has its own import taxes. You must check with your local customs broker to find out the exact percentage. This can be a significant cost.

- Installation and Training: We offer on-site installation and training as an optional service. This ensures your machine is set up correctly and your team knows how to operate it safely. This might cost $1,000 - $3,000 plus travel expenses for the engineer.

- Initial Raw Material Stock: You need to buy plastic film rolls to start production. Budget for at least a few tons to get started.

When you request a quote from us at BagMec®, we provide a detailed breakdown so you see all the potential costs clearly.

Where to Find Reliable Bag Making Machine Manufacturers in China? How to Evaluate Suppliers

Finding the right partner is the most important step. A good manufacturer provides a quality machine and supports your business long-term.

Find reliable manufacturers through online platforms like Alibaba, attending trade shows, or industry referrals. Evaluate them by checking their business license, certifications (ISO, CE), export history, customer reviews, and direct communication with their sales and engineering teams.

Your Checklist for Vetting Suppliers

Step 1: Initial Search and Shortlisting

- Online B2B Portals: Alibaba and Made-in-China.com are good starting points. Look for suppliers with a high number of years on the platform, "Gold" or "Verified" status, and a high response rate.

- Industry Trade Shows: Events like K-Show in Germany or Chinaplas in China are excellent for meeting manufacturers in person. You can see their machines and talk directly to their technical staff.

- Professional Networks: Ask for recommendations from other business owners in your industry. Word-of-mouth from a trusted source is very valuable. You can also work with companies that have large networks of suppliers.

Create a shortlist of 5-7 potential suppliers.

Step 2: Deep-Dive Evaluation

Use this checklist to investigate each supplier on your list.

| Evaluation Criteria | What to Look For | Red Flags (Warning Signs) |

|---|---|---|

| Company History & Age | At least 5-7 years of experience. We at BagMec® were established in 2017. Experience means they have likely solved many problems already. | A company that is only 1-2 years old or has changed its name frequently. |

| Certifications | ISO 9001 (for quality management) and CE (for safety standards in Europe). Ask for copies of the certificates. | Unwillingness to provide certificates or providing expired ones. |

| Export Experience | Ask which countries they export to. A company with a diverse export market (e.g., Europe, Americas, Asia) is usually more reliable. We export to over 50 countries. | They only sell domestically or cannot provide examples of international customers. |

| Factory Audit/Tour | Ask for a virtual factory tour via video call. This lets you see their workshop, assembly lines, and team. We welcome virtual tours. | Refusing a virtual tour or showing a messy, disorganized workshop. |

| Technical Expertise | Can they answer detailed technical questions? Do they have engineers on their sales team? Ask about their patented technologies, like our "Smart Tension Control". | Salespeople who only talk about price and cannot answer technical questions. |

| Communication | Is their communication clear, professional, and prompt? Do they have a website with detailed information? Their technical specifications should be clear. | Vague answers, slow responses, poor English, and a lack of professional documents. |

Never choose a supplier based on price alone. A cheap machine from an unreliable supplier will cost you much more in the long run.

What’s the Purchase Process Like? Step-by-Step Guide from Ordering to Delivery

Once you've chosen a manufacturer, what happens next? Knowing the process helps you manage your timeline and expectations. Let's walk through it.

The purchase process involves getting a detailed quote, negotiating the contract, making a down payment (usually 30%), waiting for production, inspecting the machine before shipment, paying the balance, and finally, arranging shipping and delivery.

A Typical 8-Step Timeline

Here is the process we follow at BagMec®, which is standard for most professional manufacturers in China.

-

Step 1: Inquiry and Quotation (1-3 Days)

You send us an inquiry with your requirements. We respond with a detailed quotation, including machine specifications, price, optional add-ons, and payment terms. We deliver quotes within 48 hours. -

Step 2: Technical Confirmation and Contract (3-7 Days)

We discuss all technical details to ensure the machine meets your exact needs. We then draft a Proforma Invoice (PI) or Sales Contract. This document lists everything: machine model, price, delivery time, warranty, and bank details. Read this document very carefully before signing. -

Step 3: Down Payment (1-3 Days)

You sign the contract and arrange the down payment. This is typically 30% of the total value, sent via a bank wire transfer (T/T). Production begins once we receive this payment. -

Step 4: Machine Production (30-45 Days)

We build your machine. Our standard delivery time is 45 days. Throughout this period, we can provide you with progress photos or videos. -

Step 5: Pre-Shipment Inspection and Testing (1-2 Days)

Once the machine is built, we conduct a 72-hour continuous operation test. We send you a detailed video of your machine running with your specified material. You can also visit our factory for a live inspection. -

Step 6: Balance Payment (1-3 Days)

After you approve the test video and inspection report, you arrange the remaining 70% balance payment. -

Step 7: Packaging and Shipment (5-10 Days)

Once we receive the balance, we package the machine securely in a wooden case for sea freight. We then transport it to the port (e.g., Ningbo or Shanghai) and handle the export customs clearance. We send you the Bill of Lading (B/L) and other shipping documents. The warranty period typically starts from the date the machine is shipped mtdpack.com. -

Step 8: Arrival and Customs Clearance (20-40 Days)

The machine travels by sea to your nearest port. Your customs broker will use the documents we provided to clear it through your country's customs. You then arrange for transport from the port to your factory.

Clear and constant communication is key throughout this entire process. We assign a dedicated project manager to each order to keep you informed at every step.

Conclusion

Buying a T-shirt bag machine from China is a major step. By following this guide, you can confidently navigate the process. Focus on finding a reliable partner, understanding all the costs, and planning for the long term. This ensures your investment is successful.

-

Explore this link to understand the technology and benefits of high-speed T-shirt bag machines, which can enhance your production efficiency. ↩