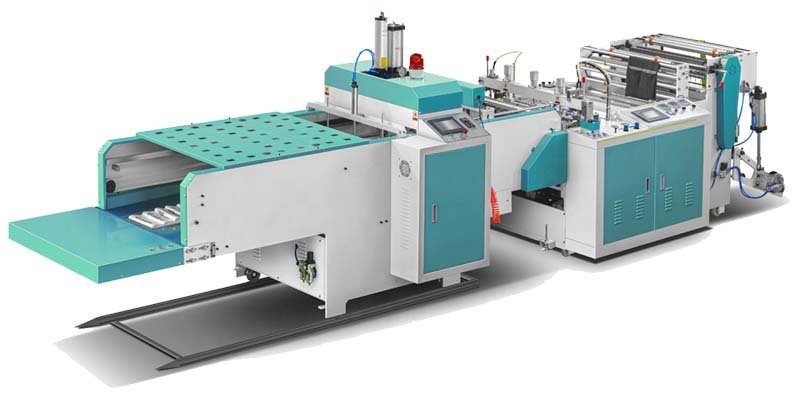

Planning a budget for a T-shirt bag making machine1 feels complicated. You see many different prices and don't know what is fair. This makes you worry about overspending on a machine or buying one that is not good enough. We made this guide to explain the costs, so you can plan your budget with confidence.

A new T-shirt bag making machine from a reliable manufacturer like us typically costs between $17,000 and $32,000. This price range covers everything from entry-level models for small businesses to fully automated systems for large-scale production.

This price difference exists because not all machines are the same. The final cost depends heavily on your specific needs. Key factors include the machine's production speed2, its level of automation3, the quality of its components, and any special features you might need, like an inline printer. A machine built for a small startup will have a very different price tag than a high-capacity system designed for a national retail supplier. Understanding these factors is the first step toward making a smart investment for your business.

In this guide, we will break down these variables in detail. We will look at how different configurations affect the price, what other costs you need to consider besides the machine itself, and how to prioritize features if you are on a tight budget. Our goal is to give you a clear and complete picture of the investment. This will help you choose the right machine that fits both your production goals and your financial plan perfectly.

What Is the Price Range for T-shirt Bag Making Machines?

To help you understand what you get for your money, we can break this price range into three main tiers. Each tier serves a different type of business and production need.

Entry-Level Machines: Approximately $17,000 – $22,000

These machines are the perfect starting point for new businesses or smaller operations. They are designed to be simple, reliable, and affordable. At this price, you typically get a semi-automatic machine. This means some manual help might be needed, for example, in collecting the finished bags. The production speed is suitable for lower volume demands. They are built to handle standard materials like LDPE and HDPE film. These machines let you enter the market without a huge initial investment.

Mid-Range Machines: Approximately $22,000 – $28,000

This tier is for businesses that are growing. If your production demands are increasing, you need a machine that can keep up. Mid-range models are often fully automatic, using a PLC control system with a user-friendly touchscreen interface. This reduces the need for manual labor and helps lower the chance of errors. They offer higher production speeds and more consistency. You might also find some of our innovative technologies here, like the "Smart Tension Control" system, which ensures the film feeds smoothly. This results in less waste and better-quality bags.

High-End Machines: Approximately $28,000 – $32,000+

High-end machines are built for large-scale, industrial manufacturing. These are fully automated systems designed for maximum efficiency and output. They have the fastest production speeds, sometimes with dual lanes to produce two lines of bags at once. These models often include our energy-saving servo motors, which can cut power use by up to 30%. They can also be customized with advanced features. This includes inline printing units for branding, special die-cutters, and systems optimized for eco-friendly materials like biodegradable PLA.

Here is a table to show the differences more clearly:

| Feature | Entry-Level Machine | Mid-Range Machine | High-End Machine |

|---|---|---|---|

| Price Range | $17,000 - $22,000 | $22,000 - $28,000 | $28,000 - $32,000+ |

| Automation | Semi-Automatic | Fully Automatic (PLC Control) | Fully Automatic (Advanced) |

| Production Speed | Standard | High | Very High (Dual-Lane Option) |

| Key Features | Basic, reliable operation | Smart Tension Control, PLC | Energy-Saving Servo, Customization |

| Ideal For | Startups, Small Businesses | Growing Operations | Large-Scale Industrial Producers |

What Are the Main Factors That Affect the Machine’s Price?

You know the price range now. So let's look at the specific factors that determine the final cost. Understanding these elements will help you see why one machine costs more than another.

The machine’s price is mainly affected by its production speed, level of automation, build quality, and any custom features. Faster, more automated machines with premium components and special functions will cost more.

Each of these factors adds value to the machine. They can improve efficiency, reduce long-term costs, or allow you to produce specialized products. Let's examine each one.

Production Capacity and Speed

The speed of the machine, often measured in bags per minute or bags per hour, is a major price driver. A machine that can produce 200 bags per minute will cost more than one that produces 100 bags per minute. Higher speed requires more powerful motors, more precise engineering, and more robust components to handle the workload without failing. For businesses serving large markets, like retail chains, a high-speed machine is a necessary investment to meet demand.

Level of Automation

Automation determines how much manual labor is required to operate the machine.

- Semi-automatic machines are cheaper. They require an operator to perform certain tasks, like loading film rolls or collecting the stacked bags.

- Fully automatic machines have a higher price. They use PLC and touchscreen controls to manage the entire process from start to finish. This reduces labor costs, minimizes human error, and ensures consistent production 24/7.

Build Quality and Materials

A machine is a long-term investment. Its durability directly impacts your return on investment. We use high-carbon steel for our machine frames to ensure stability and a long life. We also apply corrosion-resistant coatings, which is important for operations in humid climates. Better materials and construction cost more upfront. But they save you money over time by reducing maintenance, avoiding breakdowns, and lasting for many years.

Customization and Special Features

Standard machines produce standard T-shirt bags. But many businesses need special features to stand out. Each customization adds to the cost. Common additions include:

- Inline Printing Units: To print logos or designs on the bags as they are made.

- Logo Embossing Units: To create a raised logo on the bag.

- Specialized Die-Cutters: To create unique handle shapes or bag designs.

- Systems for Eco-Friendly Materials: Machines adapted to run thicker, recycled films or biodegradable PLA require special heating and sealing components.

Here is a summary of how these factors influence the price:

| Factor | Impact on Price | Why It Matters for Your Business |

|---|---|---|

| Production Speed | High | Faster speeds mean higher output, allowing you to serve larger customers and increase revenue. |

| Automation | High | Full automation reduces labor costs and errors, improving your overall operational efficiency. |

| Build Quality | Medium | High-quality materials lead to less downtime and a longer machine life, protecting your investment. |

| Custom Features | Varies | Customizations allow you to create unique products, meet specific market demands, and build a stronger brand. |

How Big Is the Price Difference Between Different Configurations?

Now, let's look at how choosing different features can really change the final price. Seeing some real-world examples will help you understand where your money is going and what you get for it.

The price difference can be huge. A basic, single-lane machine might cost around $17,000. But a fully automated, dual-lane machine with an inline two-color printer could easily cost over $30,000, depending on the exact specifications.

To make this clear, we have created three sample packages. These show how the price changes with different features. These are based on common requests we get from clients like you.

Scenario 1: The Startup Package

This package is designed for a new business or a company entering the T-shirt bag market for the first time. The goal is to get started with a reliable machine without a large upfront cost.

- Configuration: A single-lane, semi-automatic T-shirt bag machine. It has a standard production speed and basic PLC controls for setting bag length and counting.

- Estimated Price: Approximately $17,500.

- Use Case: This is perfect for a business serving a local market, like a few grocery stores or retail shops. The production volume is low to medium, and the owner is closely involved in the operations.

Scenario 2: The Growth-Oriented Package

This package is for a business that has established itself and is now ready to scale up. The focus is on increasing efficiency and output to handle more orders.

- Configuration: A fully automatic, single-lane machine with a user-friendly touchscreen interface. It features a higher production speed and includes our patented "Smart Tension Control" for less material waste. It also has a servo motor for the main drive.

- Estimated Price: Approximately $25,000.

- Use Case: This fits a company that is expanding its customer base. They need to produce more bags faster while keeping labor costs in check. The improved consistency and reliability are key.

Scenario 3: The Enterprise Package

This is the top-tier solution for a large-scale manufacturer. The priority is maximum productivity, minimal downtime, and the ability to produce high-value, branded bags.

- Configuration: A fully automated, dual-lane machine. It runs at our highest possible speed and is equipped with energy-saving servo motors on all key parts. It includes an integrated two-color inline printing unit and a robust auto-stacking system.

- Estimated Price: Approximately $32,000+.

- Use Case: This machine is for a major supplier to national supermarket chains or e-commerce companies. They need massive output, consistent quality, and branded packaging, all while keeping operational costs low.

Here is a side-by-side comparison of these packages:

| Feature | Startup Package | Growth Package | Enterprise Package |

|---|---|---|---|

| Estimated Price | ~$17,500 | ~$25,000 | ~$32,000+ |

| Automation | Semi-Automatic | Fully Automatic | Fully Automatic, Advanced |

| Production Lanes | Single Lane | Single Lane | Dual Lane |

| Speed | Standard | High | Maximum |

| Key Features | Basic, reliable core | PLC Touchscreen, Smart Tension | Full Servo Motors, Inline Printer |

| Target User | New Business | Growing Business | Large Manufacturer |

What Additional Costs Should I Consider Besides the Machine Itself?

The price on the quotation is for the machine, but it is not the total cost of your project. To create a truly accurate budget, you must plan for several other expenses.

You must budget for shipping, installation, and training. Also, think about future costs like spare parts, regular maintenance, and the ongoing cost of raw materials. These additional costs are crucial for making a realistic financial plan.

Ignoring these costs can lead to financial problems later. Let's break down each of these additional expenses so you can be fully prepared.

Shipping and Logistics

Your machine has to get from our factory in China to your facility. This cost can vary a lot depending on your location and the shipping method. We offer several international trade terms to give you flexibility:

- EXW (Ex Works): You arrange all shipping from our factory door.

- FOB (Free On Board): We handle transport to the port in China. You handle the ocean freight, insurance, and import process.

- CIF (Cost, Insurance, and Freight): We manage shipping and insurance to a port in your country. You handle import duties and transport from the port.

- DDP (Delivered Duty Paid): We handle everything, delivering the machine to your door with all duties paid. This is the most hassle-free option.

Installation and Training

Your machine is a complex piece of equipment. Proper installation is key to its performance and longevity. We offer optional on-site installation and training services. Our engineers will come to your factory, set up the machine, and make sure it runs perfectly. They will also train your operators on how to run it, perform daily maintenance, and troubleshoot minor issues. This service has a cost, but it prevents costly mistakes and ensures you get the most out of your machine from day one.

Spare Parts and Maintenance

Our machines are built to last and pass a 72-hour continuous stress test before shipment. However, some parts, known as consumables, will wear out over time. This includes items like sealing blades, Teflon tapes, and heating elements. It is a smart practice to order a basic set of spare parts with your machine. This minimizes potential downtime. You should also budget for routine maintenance to keep the machine in top condition.

Raw Materials

The machine itself is a one-time cost, but raw materials are an ongoing operational expense. You will need a steady supply of film rolls to make your T-shirt bags. The cost of this film (LDPE, HDPE, or biodegradable PLA) will be a major part of your production budget.

Utility Costs

Your new machine will need power to run. Electricity cost is another ongoing expense. We have focused on making our machines more efficient. For example, our models with energy-saving servo motors can reduce electricity consumption by up to 30%. This might mean a higher initial price, but it leads to significant savings on your power bills over the life of the machine.

If the Budget Is Tight, Which Features Should Be Prioritized?

We understand that budgets can be tight, especially for a new or growing business. If you need to make careful choices to stay within your budget, it is important to know what is essential and what is a luxury.

On a tight budget, focus on the core functions first. Prioritize excellent build quality and a reliable, consistent sealing system. These are absolutely essential for making good bags. You can always add more automation or speed later as your business grows.

Making smart choices here will ensure you get a machine that works well now and provides a solid foundation for the future. Let’s separate the "must-haves" from the "good-to-haves."

Must-Haves: The Non-Negotiable Features

These are the features you should not compromise on, no matter your budget. They are the foundation of a good machine.

- Core Functionality (Cutting and Sealing): The machine's primary job is to make bags. The cutting and sealing systems must be precise and reliable. A machine that produces weak seals or uneven cuts is useless. This is the number one priority.

- Build Quality and Durability: A machine made with cheap materials will cause endless problems. Look for a strong, stable frame, like our high-carbon steel construction. A durable machine will have less downtime and a much longer lifespan, making it a better investment.

- Essential Safety Features: Safety is not a place to cut corners. The machine must have standard safety features, like emergency stop buttons and protective covers. Machines compliant with international standards like CE are a must.

Good-to-Haves: Features to Consider Adding Later

These features are great for efficiency and convenience, but they are not strictly necessary to start production. You can begin with a more basic machine and upgrade as your profits grow.

- Full Automation: You can start with a semi-automatic machine. This requires more manual work but lowers the initial cost. You can hire an operator and still be very productive.

- Maximum Production Speed: You probably don't need the fastest machine on the market right away. A machine with a standard or medium speed can be very effective for a startup or a business serving a local area.

- Inline Printing: Printing logos directly on the machine is efficient, but you can achieve the same result with an offline process at first. You could even outsource printing until you have the volume to justify the integrated feature.

Here’s a table that summarizes these priorities:

| Feature | Priority Level | Reason |

|---|---|---|

| Reliable Sealing System | Must-Have | This is the core function. Without good seals, the bags are defective. |

| Durable Build Quality | Must-Have | A strong machine lasts longer and has fewer breakdowns, saving you money. |

| Safety Compliance (CE) | Must-Have | Protecting your operators is not optional. |

| Full Automation | Good-to-Have | Reduces labor but can be replaced by an operator at the start. |

| Maximum Speed | Good-to-Have | You can grow into higher speeds. Start with what you need now. |

| Inline Printing | Good-to-Have | Branding is important, but it can be done with a separate process initially. |

Is Buying a Second-Hand Machine More Cost-Effective? What Are the Risks?

You might find used T-shirt bag making machines for sale online. The lower price can seem very attractive, especially on a tight budget. But before you decide, you need to understand the full picture.

A used machine can be cheaper upfront, but it carries big risks. You often get no warranty, no technical support, and an unknown service history. Hidden repair costs can quickly make it a more expensive choice than buying a new machine from a trusted supplier.

While the initial saving is tempting, it is important to weigh it against the potential problems. Let's look at the pros and cons.

The Potential Saving (The "Pro")

There is really only one advantage to buying a used machine: the initial purchase price is lower. For a business with very limited capital, this can seem like the only way to get started. However, this initial saving can disappear quickly when you consider the risks.

The Hidden Risks (The "Cons")

The disadvantages of buying a used machine are significant. These are the problems you don't see in the online listing.

- No Warranty or Support: When you buy a new machine from us, it comes with a warranty and access to our after-sales support team. If something goes wrong with a used machine, you are on your own. Repair costs and sourcing help are your full responsibility.

- Unknown History and Wear: You don't know how the previous owner used or maintained the machine. Was it run 24/7? Were parts replaced with cheap alternatives? Key components could be close to failure, leading to unexpected and expensive breakdowns.

- Outdated Technology: An older machine will likely be less efficient. It will use more electricity and may produce more waste. It will also lack modern features like PLC touchscreens, advanced safety interlocks, and our energy-saving servo motors.

- Difficulty Finding Spare Parts: If the machine is an old or discontinued model, finding the correct spare parts can be nearly impossible. This can lead to very long periods of downtime while you search for a part.

New vs. Used: A Total Cost Comparison

To really see the difference, let's compare the total cost of ownership, not just the purchase price.

| Cost Factor | New BagMec® Machine | Used Machine (Hypothetical) |

|---|---|---|

| Purchase Price | $17,000 (Entry-Level) | $10,000 |

| Warranty | Included (e.g., 1 Year) | None. All repairs are on you. |

| Technical Support | Included (Lifetime) | None. You must hire a technician. |

| Installation & Training | Available as an option | Not available. You must figure it out. |

| Spare Part Availability | Guaranteed | Difficult or impossible to find. |

| Energy Efficiency | High (e.g., servo motor options) | Low (older motor technology). |

| Potential Downtime | Low (New parts, quality tested) | High (Worn parts, unknown history). |

As the table shows, the initial $7,000 savings on the used machine can be quickly erased by one major repair, a few days of downtime, or higher electricity bills. A new machine is a more predictable and secure investment.

Conclusion: Plan Your Investment with Confidence

Investing in a T-shirt bag making machine is a big step. The price ranges from $17,000 to over $32,000. Your final cost depends on the speed, automation, and custom features you choose. By understanding these factors, you can build a smart budget.

-

Understanding the average cost helps you budget effectively and avoid overspending on equipment that may not meet your needs. ↩

-

Exploring this will help you understand the value of investing in faster machines for higher output and efficiency. ↩

-

Learning about automation benefits can guide you in choosing machines that reduce labor costs and improve production consistency. ↩