Sourcing a machine from China feels risky. You worry about low quality and losing your investment. I will show you how to identify a trustworthy partner.

A reliable Chinese bag making machine supplier provides verifiable business license1s and certifications, shares real customer case studies and export records, and offers transparent proof of their quality control process. Their professional and prompt communication further confirms their dependability.

Finding a great supplier is about more than a low price. It is about securing a long-term manufacturing partner. You must verify their documents, understand their processes, and see real proof of their work. This diligence protects your investment and ensures you receive a high-performance machine that meets your exact needs. As the general manager at BagMec®, I believe complete transparency is the foundation of trust. We openly share our certifications, quality control procedures, and customer success stories. This approach helps you make an informed decision and builds confidence from day one.

This commitment to transparency is why we invite potential clients on virtual factory tours. You can see our 12+ specialized production lines and ISO 90012-certified facility in Wenzhou firsthand. It is also why we detail our patented technologies, like the "Smart Tension Control" system, which ensures consistent film feeding. We don't just tell you we are a real manufacturer; we show you. This is how we prove our dedication to quality and build lasting partnerships with businesses in over 50 countries.

Check Business License and Factory Certifications: Are They Transparent and Verifiable?

Business documents can seem overwhelming. But they contain crucial information if you know where to look. Let's break down how to verify them.

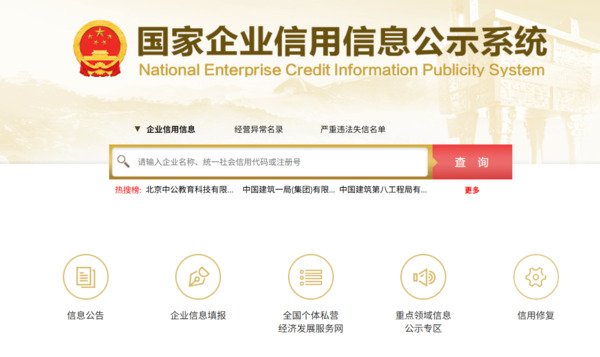

To verify a supplier, ask for their business license and check the Unified Social Credit Code (USCC) on China's official National Enterprise Credit Information Publicity System. For certifications like ISO 9001 or CE, request the certificate number and validate it on the issuing organization's website.

How to Verify a Chinese Business License

The most important document is the business license. It proves the company is legally registered. A legitimate manufacturer will provide it without hesitation.

First, ask the supplier for their 18-digit Unified Social Credit Code (USCC). Then, visit the National Enterprise Credit Information Publicity System (www.gsxt.gov.cn). While the site is in Chinese, browser translation tools make it easy to navigate.

When you look up the company, focus on these key details:

- Business Scope: Does it list "manufacturing" or "production"? A company listed only as "trading," "consulting," or "wholesale" is likely a middleman, not a factory. At BagMec®, our license clearly states "machinery manufacturing."

- Date of Establishment: This shows their experience. A company established recently may lack industry expertise. Our founding in 2017 gives us over seven years of specialized experience.

- Registered Capital: While not a perfect measure, a higher registered capital can indicate a more substantial operation.

Decoding Key Certifications

Certifications are not just logos on a website; they are proof of quality and compliance. A reliable supplier will provide the certificate numbers for verification.

| Certification | What It Means for You | How We at BagMec® Comply |

|---|---|---|

| ISO 9001 | The supplier has a proven quality management system. This ensures consistent production standards and continuous improvement. | Our Wenzhou production facility is ISO 9001 certified. It governs our entire process, from material sourcing to the final 72-hour stress test on every machine. |

| CE Mark | The machine meets European Union standards for safety, health, and environmental protection. This is essential for import into the EU and many other regions. | All BagMec® machines, from our $8,500 Patch Handle model to our $88,000 Wicketer Bread Bag Machine, are CE compliant. This is critical as 40% of our exports go to Europe and the Americas. |

| Third-Party Reports (SGS, TUV) | An independent company has inspected the supplier's factory or products. This offers an unbiased assessment of quality and specifications. | We welcome and can facilitate third-party inspections from agencies like SGS or TUV before shipment. This provides you with an extra layer of assurance. |

Red Flags to Watch For

Be cautious if a supplier shows these signs:

- They refuse to share their business license or certificate numbers.

- The documents they provide are blurry, cropped, or appear altered.

- The certifications are expired.

- Their business scope does not include manufacturing, yet they claim to be a factory.

Do They Have Real Customer Cases or Export Records?

Any supplier can claim to have global customers. But a reliable one can prove it. You need to ask for specific evidence of their experience.

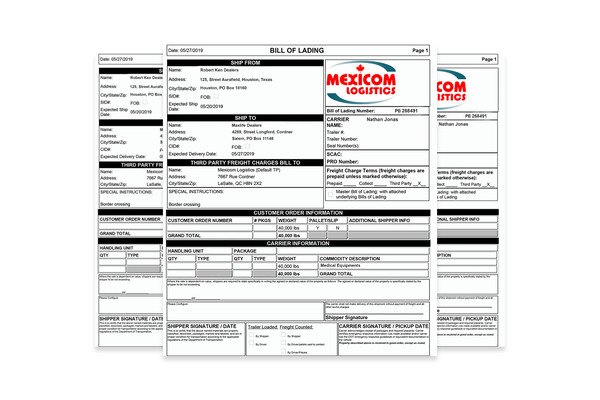

Ask for detailed customer case studies relevant to your industry and request redacted shipping documents, such as a Bill of Lading3 (B/L). These documents prove they have real-world success and experience exporting machines to countries like yours.

Moving Beyond a Logo Wall

A website page full of impressive logos is nice, but it lacks substance. You need to dig deeper to understand their experience. Ask questions that reveal the story behind the sale.

For example, when a potential client asks us for a reference, we don't just point to a logo. We share a story like that of our German packaging client. They deployed eight of our fully automated Form-Fill-Seal (FFS) bag machines. The result was a 99% uptime rate and an 18% reduction in material waste. We also talk about the logistics giant in India that needed a custom, high-speed courier bag line capable of printing QR codes, which now produces 2,500 bags per hour.

These details show we solve real-world problems.

How to Verify Export Experience

A Bill of Lading (B/L) is an official document issued by a carrier to a shipper. It details the type, quantity, and destination of the goods being carried. Ask a potential supplier to provide a B/L for a recent shipment to your country or region.

For confidentiality, the supplier will black out the buyer's name and contact information. This is standard practice. You should focus on:

- Shipper: The name should match the supplier's company name.

- Port of Loading: For us, this is typically Ningbo or Shanghai, the main ports near our Wenzhou factory.

- Port of Destination: Check if they have shipped to a port near you.

- Description of Goods: This should clearly state "Bag Making Machine" or similar specific terminology.

Industry-Specific Solutions Are Proof of Expertise

A great supplier does not just sell machines; they provide solutions. Their ability to serve specific industries is a strong indicator of their technical depth. A supplier who understands the unique demands of your market can build a better machine for you.

| Industry | Common Challenge | BagMec®'s Proven Solution |

|---|---|---|

| Retail & E-commerce | High-volume production and consistent branding. | Our T-Shirt Bag Making Machines produce up to 1,200 bags/hour. We offer custom features like logo embossing units on our Patch Handle Bag Making Machines. |

| Food & Beverage | Strict hygiene standards and maintaining product freshness. | We build food-grade packaging machines, like our Zipper Bag Machine and Lamination Pouch Machine, using FDA-compliant materials and anti-contamination designs. |

| Logistics & Courier | Bag durability and tear resistance for secure shipping. | Our Heavy Duty and Courier Bag Machines create reinforced, tear-resistant seams to protect contents during transit, a solution we developed for major logistics clients. |

| Medical & Hygiene | Aseptic production and regulatory compliance. | For clients like medical supplies manufacturers, we design specialized diaper bag production lines that meet strict hygiene and sterility standards. |

Beyond Promotional Videos: Can They Show Real Shipping or Quality Control Process?

A polished marketing video can make any factory look good. But it is often staged and may not reflect daily reality. You need unedited proof of their capabilities.

Request a live video call to see your machine running before it ships. Ask them to walk you through their quality control checks in real-time. This provides undeniable proof of their process, their facility, and the condition of your specific machine.

The Power of a Live, Unscripted View

A pre-recorded video can be years old or show someone else's factory. A live video call puts you in control. You can direct the salesperson to show you specific parts of their workshop or your machine.

During our live virtual factory tours, we encourage clients to be specific.

- "Can you show me the servo motors you use?" We'll show you the high-efficiency motors that reduce power consumption by up to 30%.

- "Can you zoom in on the sealing bar of that Side Sealing Machine?" We'll give you a close-up of the precision engineering.

- "Let me see your spare parts inventory." We'll walk you through our warehouse to show you we are prepared for after-sales support.

This live interaction removes all doubt. It shows you a real, operational factory, not just a sales office.

Demanding Proof of Quality Control

Quality is not just a buzzword; it is a process. A reliable supplier can document and prove their quality control at every stage. We built our reputation on our 5-stage inspection protocol, and we are happy to show it in action.

Our 5-Stage QC Protocol:

- Material Hardness Testing: We start by testing the raw materials, like high-carbon steel for the frame, to ensure they meet our durability standards with a tolerance of ±2%.

- Precision Alignment Verification: During assembly, our technicians use laser calibration tools to ensure every component is perfectly aligned for optimal performance.

- 72-Hour Continuous Operation Stress Test: Before it is approved, every single machine runs non-stop for 72 hours. This helps us identify and fix any potential issues with motors, electronics, or mechanical parts under real-world pressure.

- Safety Compliance Check: We test every safety feature, including the emergency stop button, safety guards, and wiring, to ensure it meets strict CE standards.

- Pre-Shipment Disassembly and Validation: We take photos and videos as we package your machine. This documents that all parts, tools, and manuals are included and securely packed for transit.

What Secure Packaging Looks Like

How a supplier packs your machine shows how much they care about its safe arrival. A machine worth tens of thousands of dollars should not be shipped carelessly. Ask for photos of the crating process. Look for a sturdy, sealed wooden crate, with the machine securely braced inside. The components should be wrapped to protect against moisture and dust. This final step is a small but critical sign of a professional operation.

What Does Their Communication Speed and Professionalism Reveal?

How a supplier communicates with you before a sale is a strong predictor of the support you will receive after the sale. Pay close attention to their responsiveness and the quality of their answers.

A dependable supplier responds within 24-48 hours with clear, technical answers to your questions. Their sales team speaks proficient English and asks intelligent questions about your production needs to propose the right solution. This signals experience and a customer-first approach.

The Good vs. Bad Communication Checklist

From my experience helping customers like Priya Kapoor, who was struggling with poor technical support from her previous vendor, I have learned to spot the difference between a professional and an amateur.

| Trait | Reliable Supplier (e.g., BagMec®) | Unreliable Supplier |

|---|---|---|

| Response Time | Within 48 hours for a detailed quote. | Takes several days to reply, or does not reply at all. |

| Clarity | Answers every question directly. Provides technical specification sheets. | Gives vague, one-sentence answers. Ignores technical questions. |

| Proactiveness | Asks about your film type (HDPE, LDPE, PLA), desired bag size, and output goals. | Only asks about your budget and when you can pay the deposit. |

| Language | Clear, professional English. Uses correct technical terms. | Many grammatical errors that cause confusion. |

| Team Access | You can speak directly with an engineer or the general manager for complex questions. | You are blocked by a single salesperson who cannot answer technical questions. |

Why Their Questions Matter

A professional supplier engages in a technical conversation. They are not just trying to sell you a machine; they are trying to configure the right machine for you.

When we ask a new client, "What material will you be running?" it is because a machine set up for LDPE might need different tension controls than one for a multi-layer laminate. When we ask, "What is your target bags-per-hour?" we are determining whether a semi-automatic machine or a fully-automated line with a PLC touchscreen is a better fit.

This consultative approach is how we help clients like Hans Fischer from Germany, who needed a zipper bag machine that met strict EU hygiene and noise-level standards. A supplier who doesn't ask these questions cannot possibly provide the right solution.

Common Traits of Reliable Suppliers: Lessons from Experience

After over seven years of manufacturing and exporting machinery, I have noticed that all the best suppliers share a few core characteristics. These are the green flags you should look for.

Truly reliable suppliers specialize in a specific type of machinery, invest in their own research and development, offer deep customization, provide robust after-sales support, and are transparent about their pricing structure. They act like a partner, not just a seller.

They Specialize, Not Generalize

Be cautious of a supplier whose catalog includes everything from bag machines to food processors to construction equipment. A true expert focuses on one thing. At BagMec®, we only build bag making machines and related equipment like slitting systems. This focus is our strength. It allows our R&D team to develop patented technologies and to deeply understand the challenges of film conversion.

They Have In-House R&D and Customization Capabilities

A top-tier supplier can adapt their machines to your unique needs. This is only possible with an in-house engineering team. A simple trading company cannot offer this. A great example is the project we did with a US-based eco-brand. They needed to work with a new type of biodegradable PLA film. We co-developed a machine with them, modifying the heating and sealing elements to handle the material perfectly. This resulted in a successful line of 100% compostable shopping bags.

Their Pricing is Transparent and Justifiable

While the final price depends on customization, a reliable supplier should be able to provide a clear price range upfront. Mystery pricing is a red flag. We are open about our cost structure because we are confident in the value we provide.

| Machine Type | Typical Price Range (USD) | Best For |

|---|---|---|

| Patch Handle Bag Machine | $8,500 - $15,500 | Retail boutiques, small-scale production |

| T-Shirt Bag Making Machine | $17,000 - $32,000 | Supermarkets, high-volume retail |

| Courier Bag Machine | $23,000 - $35,000 | E-commerce, logistics companies |

| Wicketer Bread Bag Machine | $69,000 - $88,000 | Industrial bakeries, high-speed food packaging |

This transparency helps you budget properly and compare suppliers fairly.

They Are Committed to Global After-Sales Support

The relationship does not end when the machine ships. A critical question to ask is: "What happens if I have a problem?" A reliable supplier has a clear answer. We have invested in future-ready technology, including IoT-enabled machines that allow for remote diagnostics. If a client in Mexico has an issue, our engineers in Wenzhou can often diagnose it online. We also offer optional on-site installation and training services and maintain clear communication channels for support.

Conclusion

To find a reliable Chinese bag making machine supplier, you must look beyond the price tag. Verify their business license, demand real customer cases, and inspect their quality control process. A true partner communicates professionally and invests in a long-term relationship with you.

-

Understanding how to verify a business license is crucial for ensuring supplier legitimacy and protecting your investment. ↩

-

Exploring ISO 9001 certification can help you understand quality management systems and their importance in manufacturing. ↩

-

Learning about the Bill of Lading can provide insights into shipping processes and supplier reliability in international trade. ↩