Have you ever bought garbage bags that are too small and rip open? Or maybe bags that are so big they waste material and money? This is a common problem. It leads to messy spills and inefficient operations for your business. We will show you a simple way to get the perfect fit.

To size a garbage bag correctly, you need two key measurements. For a rectangular can, calculate the bag width by measuring the can's perimeter and dividing by two, then adding two inches. For bag length, use the can's height plus four to five inches for overhang.

Getting the right size is about more than just preventing messes. It is about being efficient and saving money. At BagMec®, we build machines that produce garbage bags with exact dimensions. We understand how important the right measurements are for both homes and businesses. Our precision machinery ensures every bag produced meets your specific needs, reducing waste and improving performance. This focus on accuracy is why clients in over 50 countries trust our equipment.

We will explain the formulas for different can shapes. For a rectangular can, the width is calculated by adding the length and width of the can together. Then, you add about two inches for a good fit. For a round can, you find the circumference, divide it by two, and add two inches. The length calculation is similar for both. You take the can’s height and add extra inches to fold over the rim. This precision is a core feature of our Garbage Bag Machines.

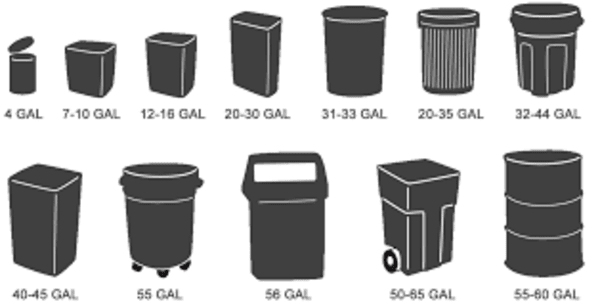

What are the standard garbage bag sizes?

Knowing the standard sizes helps you understand where your needs fit in the market. This knowledge can simplify both your purchasing decisions and production planning.

Standard garbage bag sizes range widely, from small 4-gallon bags for office bins to large 55-60 gallon drum liners for industrial use. The most common household sizes include the 13-gallon tall kitchen bag, the 30-gallon yard bag, and the 33-gallon cleanup bag.

Understanding these standards is the first step. But in the packaging industry, the real value comes from meeting specific customer demands, which often fall between these common sizes.

Household vs. Commercial Sizes

The needs for household and commercial bags are very different. Home users often want smaller bags with features like drawstrings or pleasant scents. Their trash is usually lighter. Businesses, on the other hand, need larger, thicker, and more durable bags. They have to handle heavy loads, sharp objects, or large volumes of waste from places like restaurants, construction sites, and factories.

At BagMec®, we build machines to serve both markets.

- Our T-Shirt Bag Making Machine ($17,000 - $32,000) is perfect for producing high volumes of smaller utility and grocery-style bags.

- Our Heavy Duty Bag Machine ($12,000 - $23,000) is designed specifically for the commercial market, creating thick, strong bags that can withstand tough conditions.

A Sizing Chart for Quick Reference

To make it easier, we've created a simple chart. This table shows common bag capacities, their typical uses, and the BagMec® machine best suited for their production. This helps our partners identify the right equipment for their target market.

| Capacity (Gallons) | Common Use | Can Size (Approx.) | Our Machine Solution |

|---|---|---|---|

| 4-6 Gallon | Bathroom, Office | Small Wastebaskets | T-Shirt Bag Making Machine |

| 13 Gallon | Kitchen Trash | Standard Kitchen Cans | Garbage Bag Machine |

| 30 Gallon | Yard Waste, Garage | Large Round/Rectangular | Heavy Duty Bag Machine |

| 33 Gallon | Large Cleanup, Outdoor | Large Outdoor Cans | Heavy Duty Bag Machine |

| 55-60 Gallon | Industrial, Drum Liners | 55-Gallon Drums | FFS Bag Machine |

Why Custom Sizes Are a Game Changer

Standard sizes don't work for everyone. Many modern trash cans have unique shapes and dimensions. Using a standard bag for a non-standard can leads to a poor fit, waste of plastic, and higher costs. This is where custom manufacturing provides a huge advantage.

Our Garbage Bag Machines, priced from $23,000 to $35,000, offer full customization. You can program the exact height, width, and gusset dimensions your clients need. This flexibility empowers you to serve niche markets and solve unique customer problems. For example, one of our German packaging clients used our machines to create custom-fit bags, which led to an 18% reduction in their material waste. This is the power of precision.

How does bag thickness (mil) affect choice?

Size is only one part of the equation. The thickness of the bag is just as important. It determines the bag's strength and its ability to hold waste without ripping.

A bag's thickness, measured in mils (one-thousandth of an inch), dictates its strength. Low-density bags (under 0.8 mil) are for light office trash, while high-density, heavy-duty bags (1.5 mil or more) are needed for construction debris or sharp objects.

Choosing the right thickness prevents failures and ensures the bag performs as expected. It's a balance between durability and cost.

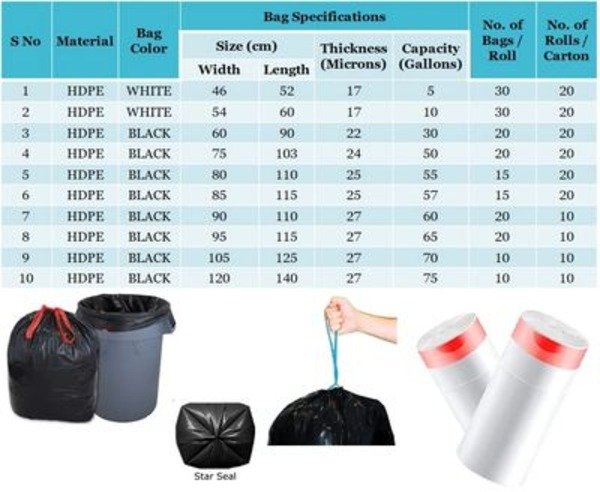

Understanding Low-Density vs. High-Density Polyethylene

The type of plastic used also affects the bag's performance. The two most common types are Low-Density Polyethylene (LDPE) and High-Density Polyethylene (HDPE).

- LDPE (Low-Density Polyethylene): This material is very flexible and resistant to punctures and tears. It can stretch, making it ideal for kitchen trash that might contain sharp-cornered boxes or other irregular objects.

- HDPE (High-Density Polyethylene): This material feels thinner but is actually very strong and can carry heavy loads. However, it is less resistant to punctures. It's best for paper waste in an office or other smooth, non-sharp trash.

Our machines are engineered to handle both film types effectively. We incorporated a patented "Smart Tension Control" system that automatically adjusts to the film's properties. This ensures consistent feeding and strong seals, whether you are running thick LDPE or thin HDPE.

Mil Thickness Guide

Here is a guide to help you match the mil thickness to the right application. This ensures you produce bags that are strong enough for the job without overspending on material.

| Mil Range | Density Type | Ideal Use | BagMec® Advantage |

|---|---|---|---|

| 0.3 - 0.7 mil | HDPE | Office paper, light trash | High-speed production with consistent quality |

| 0.8 - 1.2 mil | LDPE/HDPE | Kitchen, household waste, yard cleanup | Versatile material handling with our standard Garbage Bag Machine |

| 1.3 - 1.7 mil | LDPE | Contractor bags, heavy-duty yard work | Our Heavy Duty Bag Machine creates extra-strong bottom seals |

| > 1.8 mil | LDPE | Construction debris, industrial waste, sharp objects | Built for durability, our Heavy Duty Bag Machine ($12k-$23k) is the perfect choice |

Matching Thickness to Application

Let's look at a real-world example. A Procurement Manager like Hans Fischer in Germany needs bags for frozen food packaging scraps. The waste is heavy but not particularly sharp. He would need a medium-thickness LDPE bag, around 1.0 mil. It needs to be strong enough to hold the weight but not so thick that it is too expensive. Our machines allow for this exact calibration. This lets our partners produce the perfect bag for any job, optimizing both performance and cost.

Are there different formulas for round vs. square cans?

Yes, the shape of the trash can absolutely changes the calculation. Using the wrong formula for the can's shape is a common mistake that will always result in a poorly fitting bag.

For a square or rectangular can, the bag width is (Length + Width of can) + 2". For a round can, calculate the circumference (Diameter x 3.14), divide it by two, and then add 2" for the bag width. Bag length is Height + 4-5" for both.

Let's break down these formulas step-by-step so you can apply them correctly. These simple calculations are the foundation for producing a perfectly fitting bag.

Step-by-Step for Rectangular Cans

This is the most common can shape for kitchens and offices. Follow these simple steps.

- Measure the Can's Perimeter: Measure all four sides of the can's opening. A simpler way is to measure the two shorter sides (Width) and the two longer sides (Length) and add them all together.

- Calculate Bag Width: Divide the total perimeter by two. This gives you the flat width needed for the bag.

Formula: Bag Width = (Length + Width) + 2 inches for a comfortable fit. - Calculate Bag Length: Measure the height of the can. Add about four to five inches. This extra length provides enough material to fold over the rim of the can and prevents the bag from falling inside.

Formula: Bag Length = Height of Can + 4 inches.

Step-by-Step for Round Cans

Round cans are common for outdoor use, workshops, and large-scale waste collection. The math is a little different.

- Measure the Diameter: Measure the distance straight across the top opening of the can, passing through the center.

- Calculate Circumference: Multiply the diameter by pi (3.14). This gives you the distance around the can.

Formula: Circumference = Diameter x 3.14. - Calculate Bag Width: Divide the circumference by two. This gives you the required flat width for the bag.

Formula: Bag Width = (Circumference / 2) + 2 inches for a comfortable fit. - Calculate Bag Length: Measure the height of the can. Just like with a square can, add four to five inches for overhang.

Formula: Bag Length = Height of Can + 4 inches.

The Role of Automation in Sizing

Calculating these dimensions for every custom order can be slow and prone to errors. This is where automation transforms the production process. With a modern bag-making machine, you don't need to do the math repeatedly.

On a BagMec® machine, you simply input the final, calculated bag width and length into the PLC touchscreen interface. Our system, which features energy-saving servo motors to reduce power consumption by up to 30%, takes over from there. It precisely controls the film feeding, cutting, and sealing, producing thousands of perfectly sized bags per hour. This automation turns a complex task into a simple, repeatable, and highly efficient operation.

How does BagMec® help businesses produce the right size garbage bags?

We do more than just sell equipment. As a professional bag-making machine manufacturer, we provide complete, end-to-end solutions for precise and efficient production.

BagMec® helps businesses by offering fully customizable garbage bag machines. Our systems allow operators to program exact bag dimensions, set material thickness, and an choose sealing type. This ensures a perfect product for any client's specific application.

Our goal is to build partnerships. We empower you with the technology and support needed to succeed in a competitive market.

Precision Through Technology

Our reputation is built on engineering excellence. Every machine from our ISO 9001 certified facility in Wenzhou is designed for accuracy and durability.

- PLC Control: The master computer of the machine allows for micron-level adjustments. If your client needs a bag that is exactly 75.5 cm wide, you can deliver it with confidence.

- Touchscreen Interface: Our intuitive, multi-language UI makes it easy for operators to set up jobs, monitor production, and make quick changes.

- "Smart Tension Control": Our patented technology guarantees consistent film feeding, which is critical for uniform bag size and strong seals.

This technological foundation means our machines deliver reliable and precise performance, shift after shift.

A Solution for Every Need

We understand that every business has different needs and budgets. That’s why we offer a range of machines.

- Garbage Bag Machine ($23k - $35k): This is our versatile workhorse, ideal for producing a wide range of standard to large-sized bags for retail and light commercial use.

- Heavy Duty Bag Machine ($12k - $23k): For producers targeting industrial and construction clients, this machine offers an excellent price-to-performance ratio for making thick, rugged bags.

- T-Shirt Bag Making Machine ($17k - $32k): Perfect for high-volume production of smaller utility bags, often used in retail and grocery settings.

A startup founder like Priya Kapoor in India might choose our Heavy Duty Bag Machine to enter the market with a strong, affordable product. An established European company might invest in a fully automated Garbage Bag Machine to maximize efficiency and output. We have a solution for every stage of business growth.

From Consultation to Production

We support you through the entire process. It starts with a free engineering consultation where we learn about your business goals. We'll ask about your target market—is it retail, industrial, medical, or food service? Based on your answer, we recommend the right machine.

We did this for a US eco-brand that needed to work with biodegradable PLA films. We co-developed a machine configuration that could handle the unique properties of their material. After the sale, we offer optional on-site installation and training to ensure your team is ready for production. Our commitment is to your long-term success.

Conclusion

Sizing a garbage bag correctly requires simple formulas based on the can's shape. Bag thickness is also vital for strength. Partnering with a manufacturer like BagMec® gives you the technology and expertise to produce any size bag with precision and efficiency.