I see many packagers struggle with weak seams, wasted film, and high return rates. That pain grows when buyers post bad reviews. A strong seal at the bag’s base ends these headaches.

A bottom seal bag1 is a plastic or laminated pouch whose two film layers are welded together only along the lower edge, leaving the sides folded and the top open for filling. This design gives clean edges, strong load support, and fast machine speed.

I call the bottom seal a “single-line backbone.” Because heat or ultrasonic energy bonds just that one straight line, I can run film flat, keep web tension2 stable, and finish up to 1,200 bags each hour on my BagMec® machines. The method also cuts trim waste, so I save both resin and cash.

The details matter:

- Film travels in one web.

- A knife forms the top cut only after the lower seal cools.

- Servo pullers keep length accurate within ±1 mm.

So I get three wins—speed, strength, savings.

Why does the bottom seal work so well?

I break the idea into four points:

- Easy folding: The film runs flat and folds once, so I reduce wrinkles.

- Thick seam: The heated bar fuses two layers plus the fold, so my seam resists bursting.

- Clean top: Because the cut happens last, the filling mouth stays free of flash or angel hair.

- Simple die options: I can add punch holes, euroslots, or zipper strips without touching the seal.

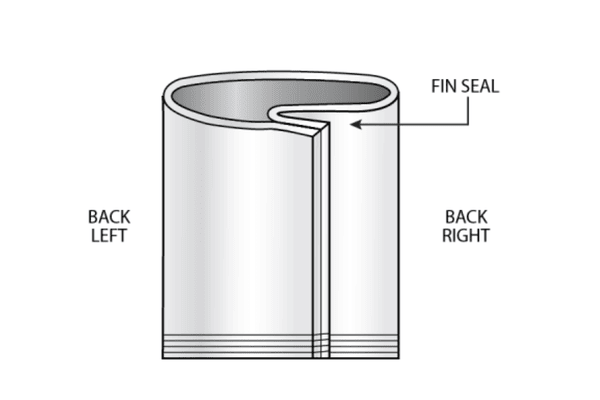

What is a fin seal bag?

I often hear clients ask, “Is a fin seal bag3 the same thing?” It is not, but the idea is close. Let me clear it up right away.

A fin seal bag3 joins the two inner surfaces of a flat web together along the back center, then folds that seal flat against the body, giving a “shark fin” profile before it is pressed. The top and bottom ends close later on form-fill-seal stations.

How the fin seal stands apart

The path of the web

In a fin seal process I guide a single web over a forming collar. The edges meet in the middle. Then a vertical sealing jaw presses them together. A second jaw folds the “fin” down. Finally, transverse jaws create the end seams.

| Step | Tool on my line | Key setting | Risk if wrong |

|---|---|---|---|

| Edge alignment | Forming collar | ±0.5 mm | Mis-registered print |

| Vertical seal | Serrated bar | 135 °C | Incomplete fusion |

| Fin flatten | Compression roller | 30 N | Thick ridge |

| End seal | Rotary jaw | 0.5 s dwell | Product leak |

Material choices

I use BOPP/CPP laminates for snacks because the fin protects the aroma. For coffee I add foil. When a customer wants recyclability, I switch to mono-PE.

When to pick a fin seal

I choose fin seal when I need:

- Barrier layers on the inside and outside.

- Tight gusset control for pillow packs.

- Continuous motion with minimal film scrap.

What is a block bottom bag?

Shoppers like a package that stands tall on a shelf. That push for shelf stability leads me to block bottom bag4s.

A block bottom bag4 is a pre-made pouch whose base is folded into a rectangular block with four crisp corners, so the bag sits upright without external support and maximizes shelf space.

The engineering behind the block

Folding sequence

- I seal the back seam.

- I insert two gusset formers.

- I push the bottom panel in, then seal the “dog-ears.”

- I add a second seal to lock the square shape.

Table: typical sizes

| Segment | Width (mm) | Depth (mm) | Height (mm) | Common fill |

|---|---|---|---|---|

| Small | 90 | 50 | 150 | Spices |

| Medium | 125 | 70 | 200 | Coffee |

| Large | 200 | 100 | 300 | Pet food |

Why I like the block bottom

- Stable base lets retailers stack.

- Extra panels offer four print faces.

- Air escapes through side vents, so the pack stays neat.

- Bottom seal stays hidden, so graphics look clean.

What is the difference between pinch bottom bags and block bottom bags?

Many buyers mix up these two styles. I lay out the facts so my clients make quick calls.

A pinch bottom bag folds and heat-seals the bottom triangular flaps, closing the base with a narrow strip, while a block bottom bag4 tucks the base into a full rectangle and seals across the entire width. The pinch gives a sharp V, the block gives a flat square.

Side-by-side view

Seal geometry

| Feature | Pinch bottom | Block bottom |

|---|---|---|

| Base shape | “V” line | Full rectangle |

| Seal length | Short, angled | Long, straight |

| Hot melt option | Yes, for paper sacks | Rare |

| Display stance | Leans unless filled | Stands empty |

Machine impact

I need a turning bar and hot-melt gun for pinch bottom paper sacks. My block bottom plastic line uses servo gusset boards and pneumatic “finger” folders. Changeover on pinch bottom runs longer because adhesive tanks must purge.

When I prefer each

- I pick pinch bottom for 25 kg cement or flour. The V-seal bears heavy loads and sits flush on pallets.

- I pick block bottom for 1 kg coffee. The flat base shows brand art and fits retail planograms.

How do I choose the right bottom seal bag machine?

Every new customer asks me this final question. The answer feels simple after I map needs to specs.

I match my product size, material, and target speed to three core machine items: web width range, sealing technology5, and control system. Then I verify CE safety and service support.

My selection checklist

Web width and draw length

If my largest bag is 600 mm wide, I buy a line with a 1,250 mm unwind because I might add a twin lane later. I set the draw length servo for 1 mm repeatability, so print stays centered.

Sealing system

- Bottom seal bar: I pick Teflon-coated aluminum for PE.

- Cooling plate: I add water chill for thick PP.

- Options: Ultrasonic units help when I run PLA because the melt temp is low.

Control and data

I choose PLCs with remote VPN. When my motor trips, BagMec techs log in and reset parameters in minutes. A 10-inch HMI stores 200 recipes. That saves my shift leader hours.

Table: BagMec® model guide

| Model | Bag width (mm) | Speed (bags/hr) | Price (USD) | Best for |

|---|---|---|---|---|

| BMB-600 | 50-600 | 1,000 | 17,000 | Grocery T-shirt |

| BMB-800 | 100-800 | 800 | 25,000 | Courier poly mailer |

| BMB-1000 | 150-1000 | 600 | 32,000 | Heavy-duty trash |

Conclusion

I now know bottom, fin, block, and pinch seals serve clear roles. By matching seal style to product need and machine spec, I ship stronger, cleaner, and faster bags every shift.

-

Explore this link to understand the advantages of bottom seal bags in packaging and their efficiency. ↩

-

Learn about the importance of web tension in packaging and how it impacts production speed and quality. ↩

-

Learn about fin seal bags and their unique sealing process that sets them apart from other packaging options. ↩ ↩

-

Find out how block bottom bags provide stability and maximize shelf space for retail products. ↩ ↩ ↩

-

Explore various sealing technologies to enhance your packaging process and product integrity. ↩