If you're planning to buy a plastic handle bag making machine, you’ve probably noticed how inconsistent the prices are. That makes budgeting difficult and choosing the right machine even harder. Let’s break it down so you can make a smart investment.

Expect to pay between $8,500 and $38,000.

- Patch handle machines: $8,500–$15,500

- Loop handle machines: $33,000–$38,000

The main driver of price is handle type, but that's just the start. Speed, automation level, and customization all factor in. Here's how each one impacts the final cost.

1. Handle Type: The #1 Price Factor

Handle type has the biggest effect on machine cost.

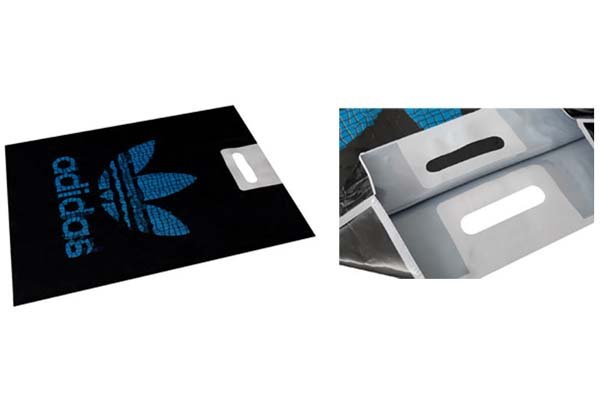

- Patch handle machines: Cheaper, simpler. They seal a reinforced film patch over the handle cutout.

- Loop handle machines: More complex and expensive. They form and attach soft loop handles using a separate subsystem.

| Feature | Patch Handle | Loop Handle |

|---|---|---|

| Price | $8,500–$15,500 | $33,000–$38,000 |

| Complexity | Low | High |

| Parts | Basic sealing station | Motorized handle-forming unit |

| Use Case | Retail, grocery, promos | Premium retail, boutique |

2. Automation: Manual vs Smart Control

Automation affects both cost and efficiency. A basic machine might need constant manual tweaks. A high-end model runs itself.

Types of Automation:

-

Semi-Automatic:

- Lower price, fewer sensors

- Needs skilled operators

- Best for low-volume operations

-

Fully Automated (PLC + HMI):

- Touchscreen control, job storage

- More consistent results

- Lower labor costs

-

Advanced Systems (Servo + Smart Control):

- Uses servo motors for accuracy

- Energy-saving (up to 30% less power)

- Features like Smart Tension Control reduce material waste

| System Type | Upfront Cost | Labor Need | Precision | ROI |

|---|---|---|---|---|

| Semi-Auto | Low | High | Moderate | Low |

| Full Auto (PLC) | Medium | Low | High | Good |

| Advanced (Servo) | High | Low | Very High | Excellent |

3. Production Speed: Faster Machines, Higher Cost

Speed drives cost. A high-speed machine needs stronger frames, better motors, and advanced cooling systems.

Speed Tiers:

-

Standard-Speed Machines:

- Lower cost, reliable for SMEs

- Good for consistent mid-volume work

-

High-Speed Machines:

- Built for 9,000+ bags/hour

- Includes servo motors and cooling systems

- Higher cost, but better ROI for large orders

| Metric | Standard Speed | High Speed |

|---|---|---|

| Cost | $12,000 | $35,000 |

| Output/hr | ~4,800 | ~9,000 |

| Labor Cost/bag | Higher | Lower |

| Ideal For | Small runs | Large-scale production |

4. Custom Features: What Adds to the Final Price?

Customizations increase price because they require unique components and testing.

Common Add-Ons:

- PLA Compatibility: For biodegradable films, needs new heaters and rollers

- In-Line Printing: Adds QR codes, logos while producing

- Custom Die-Cutters: For unique bag shapes

- Embossing Units: Adds raised logos

- Multilingual Interfaces: Software customization for HMI

| Feature | What It Does | Price Impact | Why It Adds Cost |

|---|---|---|---|

| PLA Kit | Handles compostable film | Medium | Needs precision components |

| Flexo Printer | Prints in-line | High | Full printing unit |

| Die-Cutter | Non-standard shapes | Medium–High | Custom tooling |

| Embossing | Adds raised logos | Medium | Custom rollers |

| Multi-Language UI | Adds languages to screen | Low | Software localization |

Final Thoughts

A plastic handle bag machine can cost anywhere from $8,500 to $38,000+, depending on:

- Handle style (patch vs loop)

- Automation level

- Production speed

- Custom features

Knowing where your needs fall in each category helps you get the best machine for your money—and avoid overpaying for features you won’t use.