Selecting the right bag making machine depends less on choosing between [LDPE] or [HDPE] compatibility and more on finding equipment that can handle both materials efficiently. A machine with the flexibility to adapt to different film types—flexible LDPE or rigid HDPE—ensures manufacturers can meet varying product demands without downtime or wasted materials.

Versatility is key. Modern bag making machines should seamlessly process both LDPE and HDPE by adjusting critical parameters such as temperature, tension, and sealing pressure.

At BagMec®, machines are designed with this adaptability in mind. LDPE requires lower melting points and gentle handling, while HDPE needs higher temperatures and stronger sealing force. Machines equipped with precise controls can switch between materials easily, ensuring quality results regardless of the film type.

For example, BagMec® machines use advanced PLC touchscreens that store material-specific settings or “recipes.” A patented "Smart Tension Control" system automatically adjusts for the different mechanical properties of LDPE and HDPE. These features minimize setup time, reduce errors, and improve operational efficiency.

How Do Material Properties of LDPE and HDPE Affect Machine Design?

LDPE and HDPE differ not only in flexibility and melting point but also in how they must be handled mechanically.

LDPE’s softness requires consistent, gentle tension to avoid deformation. HDPE’s rigidity demands stronger sealing and cutting mechanisms. Versatile machines must be engineered to accommodate both extremes.

This dual capability affects every component of a high-performance bag making machine. Machines that only claim to be “compatible” with both may not perform optimally. BagMec® uses an ISO 9001 certified manufacturing process to ensure components are purpose-built for this dual-material functionality.

Sealing and Cutting Mechanisms

Sealing and cutting are where material differences have the biggest impact.

-

Heating Elements: HDPE melts at approximately 130°C, while LDPE melts around 115°C. Effective machines need heaters that maintain stability across this range. BagMec® uses PID temperature control systems to hold temperatures within ±1°C.

-

Sealing Pressure: HDPE requires higher pressure due to its stiffness. BagMec® machines use reinforced pneumatic sealing systems that can adjust for either material to create strong, clean seals.

-

Cutting Blades: HDPE’s toughness can dull blades quickly. BagMec® installs high-carbon steel blades designed to retain sharpness even during high-volume HDPE runs, while still providing clean cuts on LDPE film.

| Feature | LDPE Requirement | HDPE Requirement | BagMec® Solution |

|---|---|---|---|

| Sealing Temperature | Lower, ~115°C | Higher, ~130°C | Wide temperature range with precise PID control |

| Sealing Pressure | Lower pressure | Higher pressure | Adjustable pneumatic system |

| Blade Type | Clean cut required | Durable, sharp blade needed | High-carbon steel blades |

Film Feeding and Tension Control

Feeding the film correctly is essential before it reaches the sealing stage.

LDPE’s stretchiness makes it prone to elongation under high tension. HDPE, while more stable, can slip or crease if not aligned properly. BagMec®’s "Smart Tension Control" uses sensors and servo motors to adjust in real time, preventing film drift, wrinkles, or deformation.

Can One Machine Process Both LDPE and HDPE Films?

Yes. A high-quality bag making machine can handle both materials. The critical factor is the machine’s control system.

With adjustable heat, pressure, and speed settings, a single machine can efficiently switch between LDPE and HDPE bag production.

This design philosophy allows manufacturers to adapt to shifting market needs. A machine from BagMec® can switch from producing HDPE T-shirt bags to LDPE produce bags without major retooling—just a change of settings via the touchscreen interface.

Key Features of a Versatile Machine

Not all dual-compatible machines offer equal performance. The following features define a machine’s true flexibility:

- Wide Temperature Band: Capable of sustaining temperatures from ~100°C to ~150°C with tight precision.

- Advanced PLC Control: Touchscreen interfaces allow operators to save and recall material-specific recipes.

- Servo Motor Driven: Offers precise control over pull length and speed, ensuring consistent bag sizes regardless of film type.

- Durable Mechanics: Components must withstand high stress from HDPE runs without degrading. BagMec® uses high-grade steel and corrosion-resistant materials.

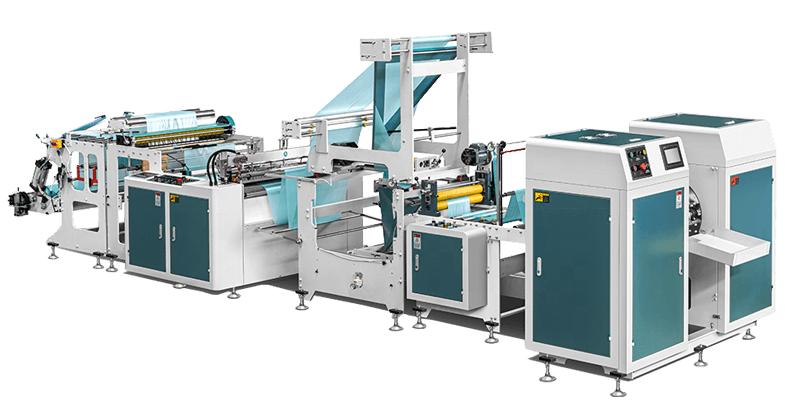

Practical Example: Side Sealing Bag Machine

BagMec®’s Side Sealing Bag Machine (priced from $10,500 to $18,500) demonstrates this adaptability.

A customer might initially produce HDPE retail bags with high sealing temperature and pressure. Later, they switch to food-grade LDPE packaging by selecting a saved PLC recipe. The machine automatically adjusts all parameters—temperature, pressure, tension—without requiring manual intervention. This kind of flexibility supports rapid scaling and contract diversification.

What Are the Cost Implications of Choosing an LDPE vs. HDPE Machine?

Initial pricing does not differ significantly between machines built for LDPE or HDPE. Operational costs, however, can vary based on material and energy use.

A versatile machine reduces total ownership cost by enabling material switching based on market conditions, thereby improving long-term profitability.

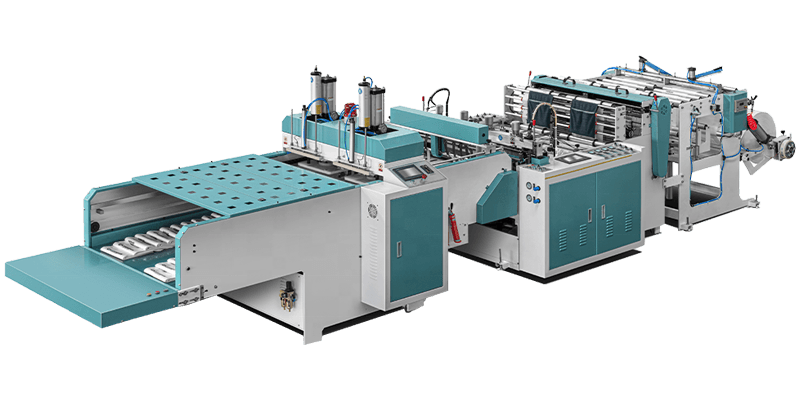

At BagMec®, pricing is based on capability and automation—not on material type. Machines such as the T-Shirt Bag Making Machine ($17,000–$32,000) and Heavy Duty Bag Machine ($12,000–$23,000) come equipped to handle both materials out of the box.

Initial Investment vs. Operational Costs

Looking beyond the purchase price, long-term operational savings are more impactful.

| Cost Factor | LDPE | HDPE | BagMec® Advantage |

|---|---|---|---|

| Initial Machine Cost | No difference | No difference | Versatile design from the start |

| Raw Material Cost | Often higher | Often lower | Ability to choose most cost-effective option |

| Energy Consumption | Lower (less heat needed) | Higher (more heat needed) | Energy-saving servo motors reduce power use |

| Production Speed | Higher speed possible | May require slower heat cycles | Optimized systems for both materials |

| Maintenance | Less wear on parts | More stress on components | Durable materials reduce repair needs |

Calculating Return on Investment (ROI)

Flexibility directly impacts ROI. A machine limited to LDPE constrains production options. A contract requiring HDPE bags becomes an opportunity missed.

With a machine that handles both:

- You can switch materials as prices fluctuate.

- You can produce diverse products—from LDPE food bags to HDPE courier bags.

- You’re positioned to test emerging materials like PLA.

This adaptability makes the machine a long-term investment rather than a fixed-cost asset.

Conclusion

Choosing between an LDPE-specific or HDPE-specific machine is no longer necessary. A machine that provides full control over all key production variables offers maximum flexibility, operational efficiency, and long-term value. BagMec® designs machines that allow manufacturers to select the best material for each job—without needing to change their equipment.