A Type 2 servo system is a high-precision control system that includes two integrators in its open-loop transfer function. This configuration allows the system to track both step (position) and ramp (velocity) inputs with zero steady-state error, enabling highly accurate motion control.

In manufacturing applications, especially those requiring consistent motion—such as bag-making—Type 2 systems offer a significant advantage. Their ability to maintain precise speeds without drift or lag is essential for operations like continuous film feeding and synchronized sealing.

BagMec® employs Type 2 servo systems in its machinery to enhance production consistency, reduce material waste, and improve overall output quality. For example, BagMec’s "Smart Tension Control" feature uses this system to keep film feed constant, even as the roll diameter changes. This consistency helps ensure smooth sealing and accurate cutting, even during rapid speed changes.

How Is a Servo Controlled?

Servo motors are controlled through a combination of hardware and software within a closed-loop system. A servo drive sends electrical signals—typically Pulse-Width Modulation (PWM)—to the motor. The width of these pulses determines the motor's target position, velocity, and acceleration.

The control process relies on three main components:

- Controller: Usually a Programmable Logic Controller (PLC) that interprets user input.

- Drive: Converts controller signals into voltage and current.

- Motor and Encoder: Executes movement and provides feedback.

Three-Level Control Architecture

Servo control operates through three nested loops:

1. Position Loop

- Purpose: Aligns the motor with the target position.

- Function: Compares target vs. actual position and outputs a speed command.

2. Velocity Loop

- Purpose: Maintains the commanded motor speed.

- Function: Compares desired vs. actual velocity and adjusts torque output.

3. Torque (Current) Loop

- Purpose: Regulates motor torque.

- Function: Converts torque commands into appropriate motor current.

| Control Loop | Input | Output | Application Example |

|---|---|---|---|

| Position | Operator command | Velocity command | Moves sealing bar to target position (e.g., 40cm). |

| Velocity | Velocity command | Torque command | Pulls film at a constant rate (e.g., 100 m/min). |

| Torque | Torque command | Motor current | Applies pressure for sealing. |

This architecture ensures rapid, precise, and repeatable motion—essential for high-speed production lines.

What Is the Main Servo Control Concept?

The foundational principle behind servo systems is the closed-loop feedback mechanism. This system continuously compares the motor’s actual output to the intended command and makes real-time corrections based on any error.

Key Components of a Closed-Loop System

- Controller (PLC): Processes operator input and generates motion commands.

- Servo Drive: Amplifies controller signals and manages motor input/output.

- Servo Motor: Executes motion based on drive input.

- Feedback Device (Encoder): Measures motor performance and relays it back to the controller.

This loop allows for precise real-time adjustments. For instance, BagMec® machines automatically correct for material variations—such as slight film thickness changes—without affecting output quality, maintaining high production rates and dimensional accuracy.

What Is the Servo Control Technique?

Servo systems commonly use a PID (Proportional-Integral-Derivative) algorithm to correct errors and achieve stable, responsive motion control.

Components of the PID Algorithm

| PID Term | Error Basis | Primary Role | Application in BagMec® Machines |

|---|---|---|---|

| Proportional | Present error | Quick response to large deviations | Fast positioning of heavy sealing components. |

| Integral | Accumulated error | Eliminates residual errors | Ensures bag length accuracy. |

| Derivative | Error rate of change | Dampens motion and prevents overshoot | Smooths acceleration and deceleration cycles. |

Each BagMec® machine is tuned for its specific use case, whether for lightweight biodegradable bags or high-strength courier pouches. PID tuning ensures motion is both stable and efficient.

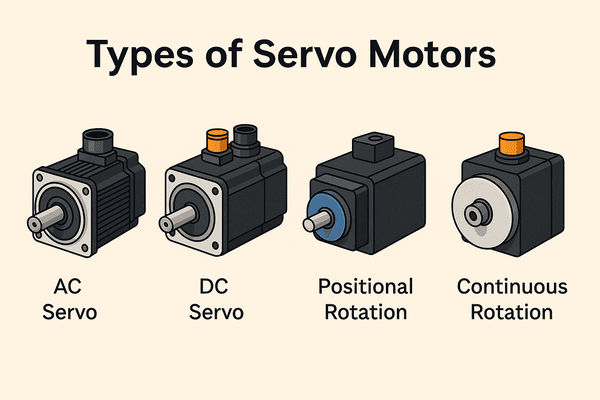

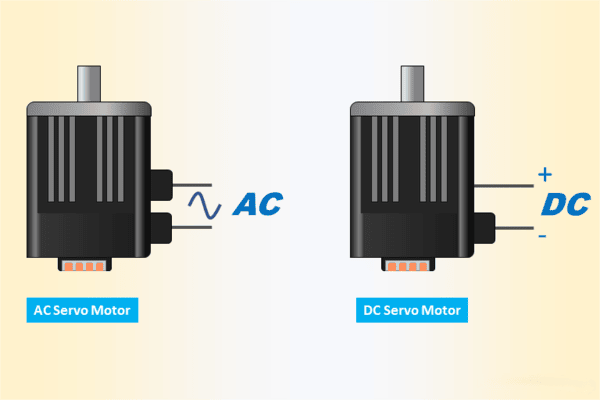

Are Servo Motors AC or DC?

Servo motors are available in both AC and DC versions. BagMec® machines use AC servo motors exclusively due to their performance, reliability, and maintenance advantages.

AC vs. DC Servo Motors

| Feature | AC Servo Motor (BagMec®) | DC Servo Motor | Operational Impact |

|---|---|---|---|

| Design | Brushless, electronically commutated | Brushed, mechanical commutation | Higher reliability and no brush wear. |

| Maintenance | Minimal | Regular brush replacement | Lower downtime and cost of ownership. |

| Performance | High torque at high speeds | Reduced torque at high speeds | Consistent output at maximum speeds. |

| Heat Management | Effective (heat in stator) | Poor (heat in rotor) | Longer motor life due to better cooling. |

| Efficiency | High | Lower due to friction losses | Reduced power consumption. |

The brushless design is particularly useful in clean production environments, while high efficiency supports energy cost savings and environmental goals.

Conclusion

A Type 2 servo system, built around closed-loop PID control, offers precise, reliable motion essential for modern manufacturing. BagMec® integrates brushless AC servo motors and finely tuned control algorithms into every machine, ensuring high performance, low maintenance, and consistent product quality across a wide range of applications.