Are you trying to pinpoint plastic bag production expenses? It can seem like a puzzle, making budgeting tough. Knowing the real costs, and how to lower them, is key to a healthy bottom line.

Industry quotes one cent for standard bags, 8-10 cents for biodegradable. BagMec® machines aim lower: achieve costs like 0.7 cents with recycled materials, thanks to our superior energy and material efficiency.

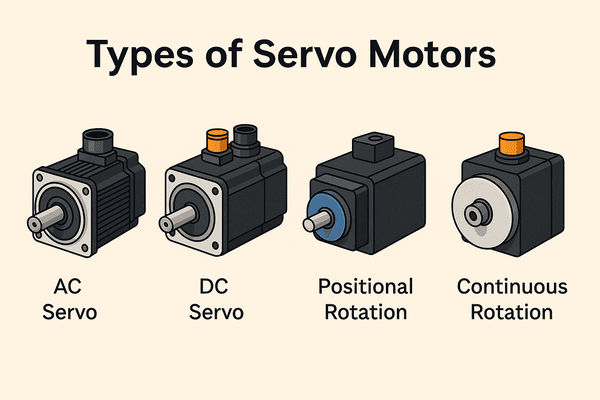

This one-cent benchmark is a starting point. Raw material prices fluctuate. The type of machine, its speed, and how automated it is play huge roles. Then, there's labor and energy. At BagMec®, our machines are built to tackle these. For instance, our energy-saving servo motors can slash power use by about 30%. Less waste and higher automation also mean your per-bag cost can dip below that typical cent.

We see clients achieve this. A simple flat bag will always cost less than a complex laminated pouch. But by optimizing film feeding with our "Smart Tension Control1" and ensuring high uptime, we help you squeeze every bit of value from your materials and operations. This means those pennies really start to add up in your favor.

How do different raw materials affect bag making costs?

Choosing your raw material is a major cost decision. It directly shapes whether you're near the one-cent mark or the higher price of eco-friendly bags.

Standard plastics like LDPE/HDPE are key to hitting the roughly one-cent per bag cost. Eco-friendly materials like PLA push costs to the 8-10 cent range. BagMec® machines efficiently process both, optimizing material use to manage these costs.

Common Plastic Bag Materials and Their Cost Implications

The type of plastic you choose impacts both the raw material expense and how smoothly it runs on machines.

| Material Type | Relative Cost | Target Cost Per Bag (Approx.) | Key Characteristics | BagMec® Machine Compatibility |

|---|---|---|---|---|

| LDPE (Low-Density Polyethylene) | Low | ~ $0.01 | Flexible, transparent, great for standard shopping bags | Yes, for shopping bag machines |

| HDPE (High-Density Polyethylene) | Low-Medium | ~ $0.01 - $0.015 | Stronger, stiffer, common for grocery bags | Yes, for flat/handle bags |

| PP (Polypropylene) | Medium | ~ $0.02 - $0.03 | Clear, strong, excellent for food packaging that needs a bit more | Yes, for food-grade packaging |

| Multi-layer Laminates | High | > $0.05 (varies widely) | Superior barrier properties, for specialty pouches like retort or medical | Yes, for laminated pouches |

Our BagMec® machines are designed for versatility. The "Smart Tension Control" system is vital here. It handles different film types with precision, reducing waste. Less waste means lower material costs, whether you're using affordable LDPE or more premium laminates.

The Rise of Biodegradable and Recycled Materials

Sustainability is a big driver now. This often means using materials like PLA or incorporating recycled content.

- PLA (Polylactic Acid): This is a popular biodegradable choice, made from resources like corn starch. It's why you see bags in the 8 to 10 cents range. While the raw material is pricier, efficient processing is key.

- Recycled Content: Using recycled LDPE or HDPE can be a smart move. It often offers a cost benefit over virgin PLA while still boosting your green credentials. The exact cost depends on the quality and availability of recycled pellets.

BagMec® is proactive in this area. Our machines are optimized for recycled materials. We also have direct experience developing machines for PLA, like for the US Eco-Brand that needed 100% compostable shopping bags. Even with more expensive biodegradable materials2, our machine efficiency helps keep the overall production cost as low as possible by minimizing waste and maximizing output.

What role does machine efficiency play in bag production costs?

Your bag making machine is central to hitting or even beating that one-cent target for standard bags. Efficiency here is not just a buzzword; it's money in your pocket.

Machine efficiency directly slashes per-bag costs. Faster machines mean more bags per hour. Automation cuts down on labor. Energy-efficient designs, like ours at BagMec®, significantly lower your electricity bills, making sub-penny costs achievable.

Let's explore this vital connection.

Automation Levels and Their Impact

The level of automation in your machine directly influences both upfront investment and daily running costs.

- Semi-automatic systems: These require more hands-on work from operators. The initial machine cost is lower. But, your labor cost per bag can be higher, making it harder to reach ultra-low production costs.

- Fully automated systems: These have a higher purchase price but offer big long-term savings. With PLC controls and touchscreen interfaces, they run with less direct labor. Our high-speed shopping bag machines, for example, can produce 1,200 bags per hour. More bags with fewer people means lower per-bag labor costs.

BagMec® provides a range from semi-automatic to fully automated lines. This way, you can match the machine to your specific volume needs and labor environment to best optimize costs.

Technological Innovations for Cost Savings

Modern machines from BagMec® include tech designed to save you money.

- "Smart Tension Control": This patented BagMec® technology isn't just about smooth running. It ensures consistent film feeding, which directly minimizes material waste. Less waste equals lower material costs per bag.

- Energy-saving servo motors: This is a big one. Our machines often feature servo motors that can cut power consumption by up to 30% compared to older or less advanced designs. Over a year, this adds up to substantial savings on your energy bills, directly impacting that per-bag cost.

- Durability and Uptime: Our machines use high-carbon steel and corrosion-resistant coatings. This means they last longer and run more reliably. The German packaging supplier who used 8 of our FFS machines saw 99% uptime and an 18% cut in material waste. High uptime means more production and lower maintenance costs per bag.

These efficiencies combined are how we help clients push their costs for standard bags below the typical one-cent mark.

Can customizing bag features increase my production expenses?

Yes, adding special features to your bags will increase costs beyond the baseline for a plain bag. But these features often add significant value.

Custom features like printing, special handles, or zippers will raise production costs above the basic one-cent mark. They might need extra machine modules or more complex operations. BagMec® helps integrate these efficiently to manage the cost increase.

Let's break down how some common customizations affect your expenses.

Common Customizations and Their Cost Factors

Tailoring bags to a brand or specific use is common. Here's how some features impact cost:

| Custom Feature | Potential Cost Impact (on top of base bag) | Reason | BagMec® Solution Available |

|---|---|---|---|

| Printing/Logo Embossing | + $0.001 to $0.005+ per bag | Requires printing units, inks, setup time, potential for slower speeds | Yes, integrated units |

| Special Handles (e.g., die-cut, patch) | + $0.002 to $0.01+ per bag | Needs specific die-cutting tools, extra material, assembly steps | Yes, precision die-cutting |

| Zippers/Closures | + $0.005 to $0.02+ per bag | Requires zipper application units, zipper material, slower production | Yes, for food-grade machines |

| Gussets (Side/Bottom) | + $0.0005 to $0.002+ per bag | Modifies bag structure, may need specific forming attachments, material use | Yes, various bag types |

Note: These are rough estimates and can vary significantly based on complexity, volume, and material.

Balancing Customization with Budget

While custom features add to the cost, they also provide benefits like better branding or product protection. Our role at BagMec® is to provide customized machinery that adds these features in the most cost-effective way. For an Indian logistics giant, we built a custom heavy-duty courier bag line. It included integrated QR code printing, handling 2,500 bags/hour. This specialized machine met their unique needs while keeping production efficient. We aim to find that sweet spot between desired features and your budget.

How does production volume influence the per-bag cost?

Production volume is crucial. Producing more bags generally means each bag costs less to make, helping you get closer to, or even below, that one-cent target.

Higher production volumes usually lead to lower per-bag costs because of economies of scale. Fixed costs are spread over more units, and you can often get better prices on bulk materials. This is key for achieving ultra-low costs.

Let's understand this better.

Understanding Economies of Scale

Economies of scale mean your average cost per unit drops as your output increases.

- Fixed Costs: Things like factory rent or the machine's purchase price are fixed. Whether you make 10,000 bags or 1,000,000 bags, these costs don't change much. So, with higher volume, each bag carries a tinier fraction of these fixed costs.

- Variable Costs: Costs like raw materials and direct energy per bag can also benefit. Buying larger quantities of resin often comes with volume discounts from suppliers.

Our BagMec® machines are built for various capacities. High-speed models making 1,200 bags/hour, for example, are designed to help you achieve significant economies of scale, driving down that per-bag cost.

Minimum Order Quantities (MOQs) and Scalability

When buying raw materials, suppliers usually have MOQs. Meeting these and buying in larger volumes can lead to better per-unit material prices.

At BagMec®, we understand businesses grow. We offer flexible MOQs for our machines, from a single prototype unit up to high-volume production lines. Our annual output of over 500 machines serves clients at all scales. This scalability means you can start at a level that suits you and expand efficiently, always aiming for the lowest possible per-bag cost as your volume increases.

Conclusion

Making plastic bags for about one cent is achievable. Biodegradable bags cost more. With BagMec®'s efficient machines, low energy use, and optimized material handling, you can often reduce these costs further. Smart choices make a big difference.