Finding clear pricing for industrial machinery can be tough. This makes budgeting hard for your business. Let's explore what impacts the final investment for your plastic polythene bag machine1.

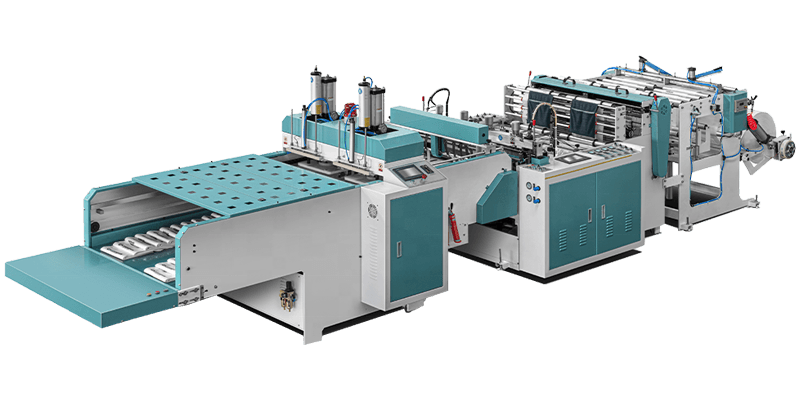

At BagMec®, our plastic polythene bag machines generally range from $8,500 to $88,000 USD. This variation depends a lot on machine type, specific features, and how much customization you need for your production line.

You might see a big price difference across the market. This is because "polythene bag machine" actually covers many different types of equipment. For example, a simpler machine designed for basic flat bags will usually cost less. On the other hand, a high-speed machine built for more complex bags, such as those with side-seals or zippers, will be a larger investment. At BagMec®, we offer a wide selection. We can build everything from entry-level units to fully automated systems. These systems are designed for various materials like LDPE, HDPE, PP films, or even advanced biodegradable PLA.

Custom features really shape the final price of a machine. Think about adding an embossing unit to put your logo on bags, or needing a precision die-cutting system for unique shapes. The level of automation is another big factor influencing cost. A semi-automatic machine is typically less expensive upfront. But, a fully automated system, often equipped with PLC control and a user-friendly touchscreen interface, represents a bigger initial investment. However, it usually gives better long-term efficiency and output. We design machines to match your specific needs for production volume and the types of material you plan to use.

What Key Factors Determine the Price of a Bag Making Machine?

So, what exactly makes one machine pricier than another? Several key elements come into play when we calculate the final cost for you to consider.

The main things affecting the price are the specific machine type (like T-shirt bag or FFS machine), material compatibility (LDPE, PLA, laminates), automation level2, custom features3 (like in-line printing), and production capacity. These define the engineering involved.

Machine Type, Bag Output, and Specific Price Ranges

The specific type of machine you need is the biggest factor affecting the price. Each machine is engineered differently to produce certain kinds of bags. Here's a look at some common machine types we offer at BagMec®, the bags they produce, and their typical price ranges:

- Patch Handle Bag Making Machine:

- Bags Produced: Creates bags with a reinforced patch handle, popular for retail and promotional use, offering a more premium feel.

- Price: $8,500 - $15,500 USD.

- Side Sealing Bag Machine:

- Bags Produced: Versatile for producing flat bags with seals on the sides, used for general packaging like clothing or stationery.

- Price: $10,500 - $18,500 USD.

- Heavy Duty Bag Machine:

- Bags Produced: Built for thicker films to make strong, durable bags for industrial applications, aggregates, or other heavy items.

- Price: $12,000 - $23,000 USD.

- Zipper Bag Making Machine:

- Bags Produced: Ideal for producing bags with re-closable zippers, for food packaging, small parts, or any product needing to be sealed and reopened.

- Price: $15,000 - $22,000 USD.

- T-Shirt Bag Making Machine:

- Bags Produced: Makes common shopping bags with handles (vest carrier bags), often found in supermarkets and retail stores.

- Price: $17,000 - $32,000 USD.

- Courier Bag Machine / DHL Multifunction Bag Making Machine:

- Bags Produced: Produces tamper-evident bags for shipping documents and goods in logistics and e-commerce, often with adhesive strips.

- Price: $23,000 - $35,000 USD.

- Garbage Bag Machine:

- Bags Produced: Designed to make various sizes of garbage bags, bin liners, or trash bags, frequently from thicker or recycled materials.

- Price: $23,000 - $35,000 USD.

- Diaper Bag Making Machine:

- Bags Produced: Specialized for producing packaging for diapers and hygiene products, focusing on specific bag styles and aseptic features.

- Price: $25,000 - $70,000 USD.

- Food Package Bag Machine:

- Bags Produced: A category for various food packaging, like pouches for snacks, grains, or frozen foods requiring hygiene and freshness.

- Price: $30,000 - $68,000 USD.

- Loop Handle Bag Making Machine:

- Bags Produced: Makes bags with soft loop handles, used for boutique shopping and heavier items, offering comfort and style.

- Price: $33,000 - $38,000 USD.

- FFS (Form-Fill-Seal) Bag Machine:

- Bags Produced: Advanced machines that form the bag, fill it (snacks, powders, liquids), and seal it, for high-volume food and consumer goods.

- Price: $34,000 - $48,000 USD.

- Lamination Pouch Making Machine:

- Bags Produced: Produces pouches from laminated films for items like food, coffee, or pet food, offering enhanced barrier properties.

- Price: $34,000 - $67,000 USD.

- Wicketer Bread Bag Machine:

- Bags Produced: Specialized for bags for bread and bakery items, often with wicket pins for easy dispensing on automated packaging lines.

- Price: $69,000 - $88,000 USD.

This list shows how the type of bag and machine complexity directly influences the investment. More specialized machines or those with higher output tend to be at the higher end of these ranges.

Material Compatibility

The materials your machine needs to handle also affect the price.

- Standard Films: Machines exclusively for LDPE/HDPE/PP films are common.

- Specialty Films: If you need to process biodegradable PLA or multi-layer laminates, the machine might require specialized tension control systems (like our "Smart Tension Control"), unique sealing technologies, or temperature controls. This adds to the engineering cost.

The table below shows a general idea:

| Material Type | Machine Feature Impact | Potential Cost Impact |

|---|---|---|

| Standard PE Films | Standard feeders, sealers | Base |

| Biodegradable PLA | Precise temperature control, gentle handling | Moderate |

| Multi-layer Laminates | Stronger sealing bars, advanced tension | Moderate to High |

Automation Levels and Custom Features

The degree of automation and any special additions you require will significantly influence the cost.

- Semi-Automatic: These machines require more operator involvement. They are less expensive initially but may have lower output and higher labor costs over time.

- Fully Automated Systems: These systems use PLC controls and touchscreen interfaces. They often integrate processes like handle punching, gusseting, or sealing in one continuous operation. While the upfront cost is higher, they typically offer higher speeds (e.g., our retail machines producing 1,200 bags/hour) and lower per-unit production costs.

- Custom Features: Adding things like logo embossing units, precision die-cutting, multi-language user interfaces, or integrated QR code printing, as seen in our Indian logistics client's machine, increases the price. Each custom feature requires specific engineering and components.

Production Capacity and Speed

Higher production capacity usually means a more powerful and complex machine.

- Output Requirements: A machine producing 200 bags per minute will be less complex and costly than one designed for 500+ bags per minute. Increased speed often necessitates more robust construction, advanced servo motors (like our energy-saving ones that reduce power consumption by 30%), and sophisticated control systems to maintain quality at high speeds.

Are Cheaper Polythene Bag Machines Always a Good Investment?

It's natural to look for a lower price when buying equipment. But is the cheapest machine always the best choice for your business in the long run?

A cheaper machine might save money initially, but it could lead to higher costs later. Think about lower output, more breakdowns, poor bag quality, or limited support. Sometimes, a very low price means compromises on durability or critical features.

The Hidden Costs of "Cheap"

A machine with a low upfront cost can sometimes come with other, less obvious expenses.

- Maintenance and Downtime: Cheaper machines might use lower-quality components. These can wear out faster. This leads to more frequent maintenance and costly production downtime. Our machines use high-carbon steel components and corrosion-resistant coatings for durability, even in humid environments.

- Material Waste: Less precise machines can lead to higher material scrap rates. For instance, our German packaging supplier achieved an 18% reduction in material waste with our FFS machines.

- Shorter Lifespan: A machine built with inferior parts may not last as long. This means you might need to replace it sooner, leading to a higher overall cost of ownership.

- Limited Support: Some low-cost suppliers might not offer comprehensive after-sales support or readily available spare parts. This can be a big problem if you face technical issues. We provide global logistics support and optional on-site installation and training.

Value Beyond the Initial Price Tag – What We Focus On

At BagMec®, we believe in providing long-term value.

- Durability Assurance: We use high-quality materials and conduct rigorous testing, including a 72-hour continuous operation stress test, to ensure our machines are built to last.

- Efficiency and Innovation: Our patented technologies like "Smart Tension Control" and energy-saving servo motors are designed to improve your operational efficiency and reduce running costs.

- Reliability: Our customer case with the German packaging supplier highlights 99% uptime. This kind of reliability is crucial for consistent production.

- Future-Ready Technology: We offer IoT-enabled machines with remote diagnostics and predictive maintenance. This helps you stay ahead.

How Can I Get an Accurate Quote for My Specific Needs?

Because every business has unique production requirements, a general price list isn't always helpful. So, how do you get a price that truly fits your needs?

To give you an accurate quote, we at BagMec® need to understand details like your desired bag type, dimensions, materials, target output speed, and any special features such as printing or unique seals. This helps us tailor the machine perfectly.

Information We Need From You

To prepare a precise quotation, we typically ask for the following details:

| Information Category | Specific Details Needed | Why It's Important |

|---|---|---|

| Bag Specifications | Type (flat, T-shirt, zipper, side-seal, FFS etc.), width, length, gusset | Determines basic machine configuration and size. |

| Material Details | Type (LDPE, HDPE, PLA, laminate), thickness (microns/gauge) | Affects sealing units, tension control, film feeding. |

| Production Needs | Bags per minute/hour, hours of operation per day | Influences motor power, automation level, machine robustness. |

| Custom Features | Printing (in-line/off-line), punching, embossing, special seals | Requires integration of additional modules or systems. |

| Automation Level | Semi-automatic or fully automatic (PLC, touchscreen) | Impacts complexity, speed, and labor requirements. |

| Existing Setup (if any) | Information about current production lines or challenges | Helps us understand your context and potential upgrades. |

For example, Hans Fischer in Germany needed a high-speed zipper bag machine for frozen food meeting EU hygiene standards. Priya Kapoor in India looked for a compact courier bag machine under $50,000 with good technical support. These diverse needs require different machine solutions.

Our Quoting Process at BagMec®

We aim to make this process smooth and transparent.

- Initial Consultation: Contact us with your requirements. Joshua Wei, our General Manager, or a member of his team will discuss your project.

- Needs Analysis: We review your specifications in detail. We might ask follow-up questions to ensure we understand everything.

- Solution Proposal: Our engineers design a machine configuration that meets your needs and budget.

- Quotation Delivery: We deliver a detailed quote, usually within 48 hours. This includes machine specifications, price, payment terms, and delivery times.

- Further Discussion: We are available to answer any questions and can even schedule a virtual factory tour.

You can request a free engineering consultation by emailing info@bagmec.com or visiting www.bagmec.com.

Conclusion

Choosing a polythene bag machine involves more than just price. It's about finding the right machine type, like a T-shirt bag or FFS machine, that fits your bags and budget, and partnering with a supplier like BagMec® for lasting quality.

-

Explore this link to understand the various types of polythene bag machines and their specific applications, helping you make an informed decision. ↩

-

Learn about the significance of automation levels in machinery, which can greatly influence efficiency and long-term costs for your business. ↩

-

Discover how custom features can enhance the functionality of machinery and impact pricing, ensuring you choose the right options for your needs. ↩