Ever wondered if making plastic bags is simple? It seems like they are everywhere. Without the right knowledge and tools, it can be a real challenge. But with modern machinery, the process is actually quite efficient.

Yes, producing plastic bags is straightforward with the right automated equipment. The core steps are film extrusion, optional printing, and then the automated cutting and sealing process by a bag making machine1. It's a defined, systematic manufacturing flow.

The journey from tiny plastic pellets to a finished, ready-to-use bag might look complex from the outside. However, the entire operation is broken down into distinct, manageable stages. First, the raw plastic material is transformed into a continuous sheet of film. If branding or designs are needed, this film then passes through a printing stage. Finally, specialized machines take over. They cut the film to the precise size and then seal it to create the individual bags. We at BagMec® have spent years perfecting machines for each of these critical steps.

Let's break this down a bit more.

- Plastic Resin Transformation: This is the birth of the bag's material. Plastic pellets are melted and then formed into a giant, thin bubble of plastic. This bubble is then cooled and flattened into rolls of film.

- Adding Visuals (If Needed): For printed bags, these film rolls go to a printing press. Here, inks are applied to create logos, text, or any desired graphics.

- Creating the Bag: The plain or printed film is then fed into a specific bag making machine. This machine handles the cutting, the sealing of edges, and often, the creation of handles or other features. Our BagMec® machines are designed for precision and speed in this final stage.

What are the key machines in the plastic bag production line?

So, we've talked about the process. But what actual machinery makes this happen? Understanding the equipment helps to see how streamlined production can be.

The essential machines include a film blowing machine2 to create plastic film, a printing machine for any designs, and a bag making machine which cuts, seals, and finalizes the bags. Each machine performs a critical, distinct function.

The Film Blowing Machine: From Pellet to Film

This is where everything begins.

The film blowing machine takes raw plastic resin – materials like LDPE (Low-Density Polyethylene), HDPE (High-Density Polyethylene), PP (Polypropylene), or even biodegradable options like PLA.

- Melting & Extrusion: The pellets are fed into an extruder, melted, and forced through a circular die. This forms a continuous tube of molten plastic.

- Inflation & Cooling: Air is blown into this tube, expanding it like a bubble to achieve the desired film thickness and width. The bubble is then cooled by air rings.

- Flattening & Winding: Once cooled, the bubble is collapsed and flattened by nip rollers. It is then wound onto cores, creating large rolls of plastic film.

Our BagMec® machines often incorporate features like our "Smart Tension Control." This ensures the film is fed consistently, which is vital for the quality of the film and the efficiency of subsequent processes.

| Feature | Description | Benefit for Production |

|---|---|---|

| Material Hopper | Stores and feeds plastic resin into the extruder. | Continuous material supply. |

| Extruder Screw | Melts and homogenizes the plastic. | Consistent melt quality. |

| Die Head | Shapes the molten plastic into a tube. | Uniform film formation. |

| Air Ring | Cools the inflated bubble rapidly and evenly. | Controls film properties, prevents defects. |

| Nip Rollers | Flatten the bubble and pull the film. | Consistent film tension and width. |

| Winder Unit | Collects the finished film onto rolls. | Easy handling for next production stage. |

The Printing Machine: Adding Brand Identity

If the bags require branding, logos, or any decorative elements, a printing machine is the next step.

The rolls of film from the blowing machine are unwound and fed through the printer.

- Flexographic Printing: This is a common method. It uses flexible relief plates and fast-drying inks. It's great for high-volume printing on various film types.

- Gravure Printing: This method uses engraved cylinders. It can achieve very high-quality prints with fine detail, often used for premium packaging.

The choice of printing machine depends on the desired print quality, volume, and complexity of the design. Synchronization between the printer and the subsequent bag making machine is important if an in-line process is used.

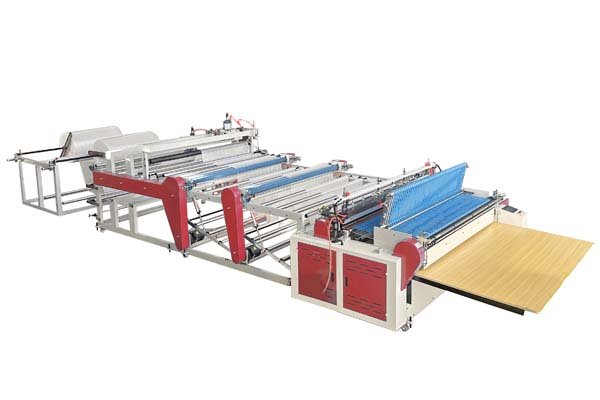

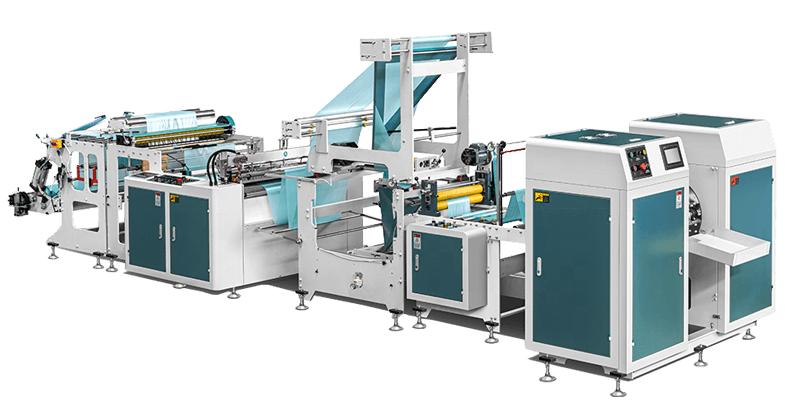

The Bag Making Machine: The Final Assembly

This is the heart of the bag production and where our BagMec® expertise truly shines. The bag making machine takes the plain or printed film rolls and transforms them into finished bags.

The general operation involves:

- Unwinding and Feeding: The film roll is unwound and fed into the machine.

- Sealing: Heated bars or wires create the bottom and side seals of the bag. The type of seal (e.g., bottom seal, side seal) depends on the bag type.

- Cutting: A blade cuts the film to separate individual bags.

- Additional Operations (if any): This can include handle punching (for T-shirt bags), patch handle application, zipper insertion, or wicket hole punching for bread bags.

At BagMec®, we manufacture a diverse range of these machines:

- T-Shirt Bag Making Machines: For common shopping bags, often with automated handle punching. (Price: $17,000-$32,000)

- Side Sealing Bag Machines: For boutique bags, courier envelopes, and other flat bags. (Price: $10,500-$18,500)

- Food Package Bag Machines: Designed for food-grade materials, sometimes incorporating zipper applicators. (Price: $30,000-$68,000)

- Wicketer Bread Bag Machines: Produces bags stacked on wickets for automated bakery packaging. (Price: $69,000-$88,000)

- Heavy Duty Bag Machines: For producing strong bags for industrial goods or waste. (Price: $12,000-$23,000)

Each machine is designed for specific bag types and production volumes, ensuring optimal performance.

How does machine customization3 impact production outcomes?

Choosing standard machines is one option. But what if you have specific needs? This is where customization options for your machinery become very important.

Machine customization allows you to tailor production to exact bag specifications, material types, and desired output. This directly impacts efficiency, reduces waste, and can create unique products, enhancing your market competitiveness.

Matching Machine to Material and Bag Type

Not all plastic films behave the same. Different materials like LDPE, HDPE, PP, or biodegradable PLA have unique properties.

- Material Compatibility: A customized machine can be fine-tuned to handle specific film characteristics – its thickness, elasticity, and sealing temperature. This ensures strong seals and smooth operation. Our BagMec® machines are designed for versatility but can be further optimized for specific material challenges.

- Specialty Bag Features: Do you need a unique handle, a specific type of seal, or integration of features like embossing or die-cutting?

- Logo Embossing Units: Can be integrated to add subtle branding.

- Precision Die-Cutting: For unique shapes or cut-outs.

- Multi-Language UI: For facilities with diverse teams.

We often work with clients like Priya Kapoor from India, who needed a compact courier bag machine under $50,000 with robust technical support, or Carlos Mendez in Mexico, who required an aseptic diaper bag machine. These require specific design considerations.

Automation and Output Levels

The level of automation significantly impacts production speed and labor costs.

- Semi-Automatic vs. Fully Automated:

- Semi-automatic systems might require more operator involvement for certain tasks.

- Fully automated systems, like those featuring PLC control and touchscreen interfaces offered by BagMec®, minimize manual intervention. This leads to higher speeds (e.g., our retail shopping bag machines can produce 1,200 bags/hour) and greater consistency.

- Integration with Other Systems: Customization can also mean better integration with upstream (printing) or downstream (packing) equipment, creating a more seamless production line.

Future-Proofing and Sustainability

Thinking ahead is key.

- Upgradability: Can the machine be upgraded later with new modules or features? This is a consideration in our design process.

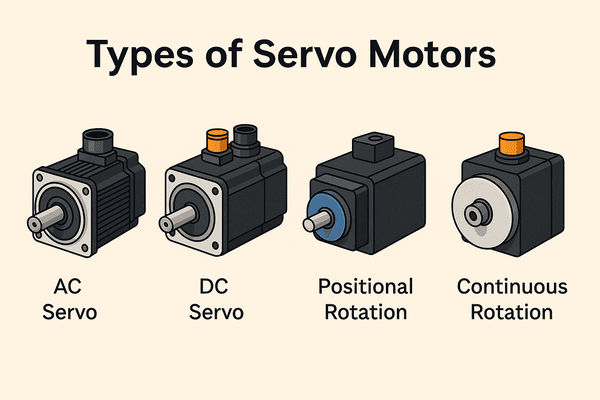

- Sustainability Focus: We design machines optimized for recycled or biodegradable materials. Our energy-saving servo motors, for example, can reduce power consumption by up to 30%. This was a key factor for a US eco-brand we partnered with to co-develop machines for 100% compostable PLA shopping bags. These initiatives not only save operational costs but also align with growing environmental concerns.

Our "Future-Ready Technology" includes IoT-enabled machines for remote diagnostics, which helps in predictive maintenance and minimizes downtime.

Conclusion: Is it Easy? With the Right Partner, Yes.

So, producing plastic bags involves clear steps and specific machinery. While it requires investment and know-how, it's not overly complex with today's technology. With quality machines and good support, like we offer at BagMec®, you can achieve efficient, high-quality bag production.

-

Explore this link to understand the technology behind bag making machines and their role in efficient production. ↩

-

Learn about the film blowing machine's process and its importance in creating plastic film for bags. ↩

-

Discover how customizing machinery can enhance production efficiency and product quality in manufacturing. ↩