Are you wondering what machinery is essential to start producing plastic bags? The variety of options can seem overwhelming, and choosing the wrong equipment can be a costly mistake. We're here to simplify it and show you what's needed.

To make plastic bags, you generally need two main types of machines: first, a film extrusion machine1 to produce the plastic film from raw resin. Second, a specialized bag-making machine then converts this film into the final bags by cutting, sealing, and adding features.

The journey from tiny plastic pellets to a finished bag involves a couple of key steps. Think of it as a production line. First, you need to create the base material – the plastic film. This is done using film extrusion machines, where plastic resins like Polyethylene (PE) or Polypropylene (PP) are melted and formed into a continuous thin sheet or tube of film. This film is then wound into large rolls. After that, these rolls of film are taken to a separate bag-making machine. This is where the actual bag takes shape. The machine will cut the film to the right size, seal the edges to form the bag's structure, and can also add handles, print designs, or create special features depending on the type of bag you want to make. Many manufacturers offer such equipment, like those found on Alibaba for T-shirt bags or film blowing machines.

How are T-Shirt Bags Made?

T-shirt bags are so common in daily life, for groceries or general shopping. Ever wondered about the specific machines that churn these out in large numbers?

Making T-shirt bags involves a film blowing machine to create rolls of HDPE or LDPE film. Then, a dedicated T-shirt bag making machine automatically feeds this film, seals it, cuts it into bag shapes, and punches out the characteristic handles.

Core Machinery for T-Shirt Bags

- Film Blowing Machine: This is where it all begins.

- Raw Material: Typically, High-Density Polyethylene (HDPE) pellets are used for their strength and thinness, though Low-Density Polyethylene (LDPE) can also be used.

- Process: The pellets are melted in an extruder, then forced through a circular die to form a continuous tube of plastic, often called a bubble. This bubble is cooled and then flattened by nip rollers to create a lay-flat film, which is then wound into rolls.

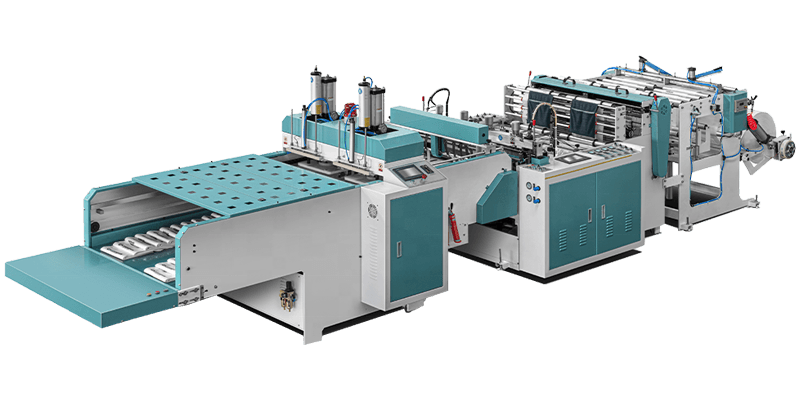

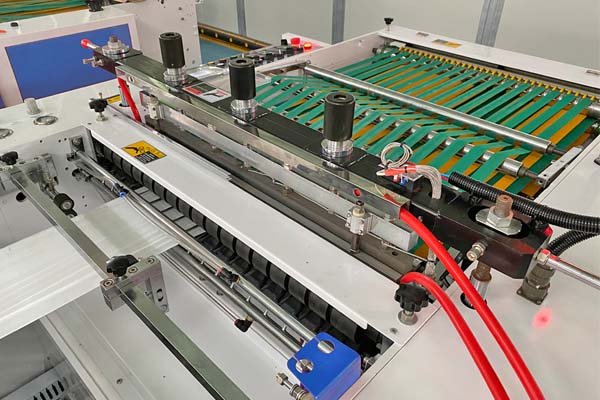

- T-Shirt Bag Making Machine2: This machine takes the film rolls and transforms them.

- Process: The film is unwound and fed into the machine. It's often printed on first if designs are required. Then, heat sealing bars create the bottom seal of the bag. A cutting unit shapes the bag and cuts out the "T-shirt" style handles. Finally, the bags are often stacked or bundled automatically.

- At BagMec®, our T-Shirt Bag Making Machines range from $17,000 to $32,000, designed for efficiency and durability.

Key Steps in T-Shirt Bag Production

| Step | Machine/Component | Input Material | Output |

|---|---|---|---|

| Resin Melting | Extruder (part of Film Blower) | HDPE/LDPE Pellets | Molten Plastic |

| Film Bubble Formation | Die Head & Air Ring | Molten Plastic | Inflated Film Tube |

| Film Cooling & Winding | Cooling System & Winder | Film Tube | Roll of Plastic Film |

| Bag Sealing & Cutting | T-Shirt Bag Making Machine | Roll of Plastic Film | Individual Bags |

| Handle Punching | Punching Unit (on bag machine) | Individual Bags | Finished T-Shirt Bags |

This setup enables high-volume production of a very popular bag type.

What Machines Produce Garment Bags?

Garment bags, those thin plastic covers from the dry cleaner or for new clothes, serve a protective purpose. What's the machinery behind these simple but useful items?

To produce garment bags, you need a film extrusion machine (often for LDPE or PP film) to make the plastic film. Then, a side sealing bag machine cuts and seals the film, usually creating a shaped shoulder and an opening for a hanger.

Let's look closer at the specifics.

Essential Machines for Garment Bags

- Film Extrusion Machine:

- Raw Material: LDPE is common for its softness and clarity. Polypropylene (PP) might also be used for a crisper feel.

- Process: Similar to T-shirt bag film, but the film characteristics (thickness, softness) are tailored for garment protection. The output is a roll of flat film.

- Side Sealing Bag Making Machine: This machine is key for the unique shape of garment bags.

- Process: The roll of film is fed into the machine. It often includes a unit to create a sloped cut for the shoulders of the garment bag. Side sealing bars create the bag's side seams. A punch unit may create a hole for the hanger hook. The bottom is typically sealed and cut.

- Our BagMec® Side Sealing Bag Machines, priced between $10,500 and $18,500, are perfect for this application.

Features of Garment Bag Production

| Feature | Machine Operation Detail | Material Aspect |

|---|---|---|

| Film Feed | Unwinds film roll from extruder | Usually LDPE or PP film |

| Shaped Top | Special cutting die for sloped shoulders | Film needs to cut cleanly |

| Side Seals | Heat sealing bars create bag edges | Consistent seal strength required |

| Hanger Opening | Punching unit for hanger hook hole | Precise positioning needed |

| Bottom Seal/Cut-off | Seals bottom and separates individual bags | Clean cut-off important |

The result is a lightweight, protective bag perfectly suited for clothing.

How Do You Make Food Packaging Bags?

Food packaging bags have specific requirements for safety, freshness, and sometimes product visibility. What machines are involved here?

Food packaging bags commonly require film extrusion (sometimes co-extrusion for multi-layer films), potentially a lamination machine if barrier properties are needed, and then specialized pouch making machines such as zipper bag machines or Form-Fill-Seal (FFS) machines.

This area is quite diverse.

Machinery for Food-Grade Bags

- Film Extrusion (and Co-Extrusion):

- Raw Materials: Food-grade PE, PP, PET, and sometimes more complex barrier materials like EVOH or Nylon for extended shelf life.

- Process: Single-layer films are made with standard extruders. For multi-layer films (e.g., for enhanced oxygen barriers), co-extrusion machines are used, which combine different molten plastics into a single composite film.

- Lamination Machine3 (Optional but common):

- Process: If different layers (like printed film, barrier film, sealing film) are produced separately, a lamination machine bonds them together.

- Specialized Bag/Pouch Making Machines:

- Food Package Bag Machines: Our machines in this category ($30,000 to $68,000) can handle various food-safe films.

- Lamination Pouch Making Machines: Specifically for creating pouches from laminated films, these machines (our price: $34,000 - $67,000) can make stand-up pouches, three-side seal pouches, etc.

- Zipper Bag Making Machines: For resealable bags, these machines ($15,000 - $22,000 at BagMec®) integrate a zipper application unit.

- FFS (Form-Fill-Seal) Machines: These are highly automated systems that form the bag, fill it with product, and seal it all in one continuous operation. We offer FFS bag machines from $34,000 to $48,000.

Key Considerations for Food Packaging Machinery

| Aspect | Machine Capability Needed | Material Implication |

|---|---|---|

| Food Safety | FDA-compliant materials, hygienic design | Non-toxic, non-contaminating |

| Barrier Properties | Co-extrusion or lamination for O2/moisture barrier | Multi-layer films common |

| Seal Integrity | Strong, reliable seals to prevent leakage/spoilage | Proper sealing temperature/pressure |

| Special Features | Zipper insertion, tear notches, stand-up gussets | Requires specific machine modules |

Choosing the right set of machines depends heavily on the type of food product and its packaging requirements. Some companies like JANDI'S Industrial Co., Ltd. also specialize in machinery for plastic film and bag production linkedin.com.

What's Involved in Making Heavy-Duty Bags?

For tougher applications like construction debris, industrial parts, or large volume waste, heavy-duty bags are a must.

Making heavy-duty bags, such as garbage bags or industrial sacks, uses robust film extrusion lines for thicker LLDPE or HDPE films. Powerful heavy-duty bag making machines then provide strong seals and can create features like gussets for increased capacity.

Strength and durability are key here.

Machinery for Strength

- Heavy-Duty Film Extrusion Line:

- Raw Material: Linear Low-Density Polyethylene (LLDPE) is very common for its excellent puncture resistance and strength. Thicker gauge HDPE can also be used.

- Process: Extruders need to handle larger volumes and produce thicker films. The cooling process is also critical for thick films to ensure quality.

- Heavy-Duty Bag Making Machine:

- Process: These machines are built to handle thicker, tougher films. They feature very strong sealing bars to ensure the integrity of the seals under heavy loads. They can often create side gussets (to give the bag a more squared-off bottom and extra volume) or bottom gussets. For garbage bags, perforation units are common to create bags on a roll.

- At BagMec®, our Heavy Duty Bag Machines are priced from $12,000 to $23,000, and our specialized Garbage Bag Machines range from $23,000 to $35,000.

Critical Aspects of Heavy-Duty Bag Production

| Feature | Machine Requirement | Film Characteristic |

|---|---|---|

| Film Strength | Ability to extrude consistent, thick film | High puncture/tear resistance (LLDPE) |

| Seal Strength | High-pressure, consistent temperature sealing bars | Must not fail under load |

| Gusseting | Units to fold and seal side or bottom gussets properly | Adds volume/capacity |

| Perforation | For bags-on-a-roll (common for garbage bags) | Clean, easy tear-off |

Businesses like Vishva Machinery also offer various types of packaging machines, indicating a diverse market for these solutions.

Conclusion

To make plastic bags, you need film extrusion machines for creating the film and various specialized bag-making machines for forming T-shirt, garment, food, or heavy-duty bags. We at BagMec® provide a wide range of these machines tailored to your production needs.

-

Explore this link to understand the critical role of film extrusion machines in plastic bag production, enhancing your knowledge of the manufacturing process. ↩

-

Discover the intricacies of T-Shirt Bag Making Machines and their efficiency in producing bags, which is essential for anyone in the industry. ↩

-

Learn about the importance of lamination machines in food packaging, ensuring product safety and freshness, crucial for manufacturers. ↩