Are you looking for the right machines to make paper bags? It can seem complex with so many options. We at BagMec® help you understand exactly what's needed.

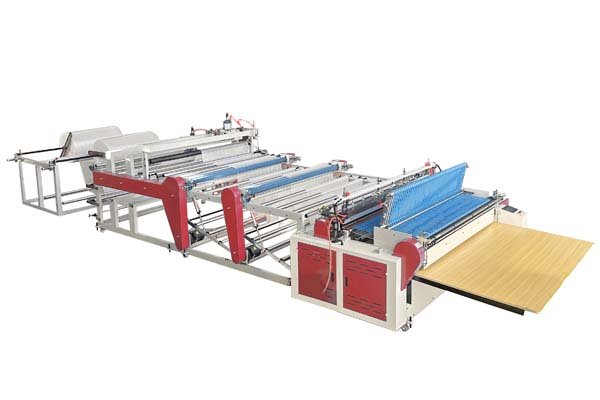

Several types of machines make paper bags. These include main paper bag forming machines1, handle making units, and printing machines2. The forming machines create different styles, like square bottom or V-bottom bags.

At BagMec®, we know that making a paper bag involves several precise steps. It’s not just one machine, but a system working together. The main machine, the paper bag former, creates the basic bag shape. Other machines or units might then add handles for carrying. Printing machines can also be used to add your brand's logo or designs. This creates a complete, ready-to-use paper bag. We offer a range of machines to cover all these production needs effectively.

For instance, our paper bag forming machines take care of key tasks. These include feeding the paper, shaping it into a tube, cutting it to the right length, and gluing the bottom. If you need bags with handles, a separate handle making machine or unit creates the handles first. These handles are then attached to the bag. Printing machines can apply your designs onto the paper before it’s made into a bag, or sometimes after. We ensure all these machines and units work together smoothly. This allows for very efficient paper bag production for your business.

How does a basic paper bag forming machine work?

Ever wonder how a flat sheet of paper becomes a useful bag? It is a very interesting automated process inside a machine. Let's take a closer look at how this happens.

A basic paper bag forming machine takes a roll of paper. It feeds the paper, forms it into a tube, cuts individual bag lengths, and then glues the bottom. This process creates either flat bags, sometimes called satchel bags, or sturdy square bottom bags.

The journey of paper inside one of our machines is quite precise. We design our machines for reliability and quality output.

The Paper's Journey in Our Machines

At BagMec®, our paper bag forming machines start by carefully taking paper from a large roll. This roll is the main raw material for your bags.

The machine then unrolls the paper smoothly. We have systems like our "Smart Tension Control" (a BagMec® patented technology). This system makes sure the paper feeds through the machine without any jerks or slack. This consistent tension is very important. It helps prevent the paper from tearing or jamming. It also ensures each bag is made to the correct size.

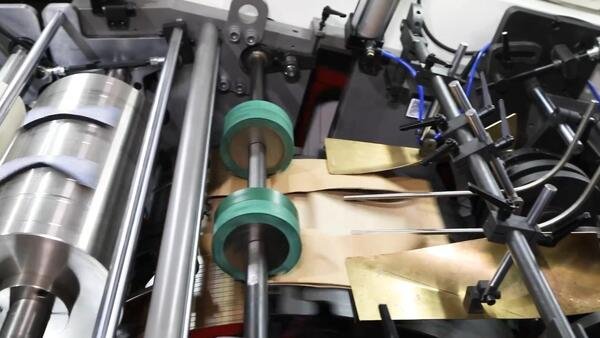

Next, the flat paper web goes into a forming section. Here, specialized parts fold and shape the paper into a continuous tube. Precision gluing systems apply adhesive along the edge of the paper. This seals the side of the tube securely and cleanly.

Creating the Bag Shape and Bottom

Once the long paper tube is formed and sealed, it moves to a cutting unit. Here, the machine cuts the tube into individual bag lengths. The cutting is very accurate.

Then, the bottom forming section takes over. For square bottom bags, this involves a complex series of folds, tucks, and creases. The machine then applies glue to specific points to seal the bottom. This creates a flat base so the bag can stand up. For V-bottom bags, also known as flat or satchel bags, the bottom forming process is simpler. The end of the tube is folded and glued to create a V-shaped seal. MTED mentions RZJD-250J machines for flat and satchel paper bags.

Types of Bag Forming Machines We Offer

We provide different types of paper bag forming machines to meet diverse needs.

| Machine Type | Common Uses | Key Feature at BagMec® |

|---|---|---|

| Square Bottom Bag Machines | Shopping bags, takeaway food bags, gift bags | High speed, options for inline handle unit |

| V-Bottom Bag Machines | Bakery bags, pharmacy bags, small retail items | Efficient, reliable for high-volume flat bags |

| Two-Sheet Paper Bag Machines | Heavy-duty bags, larger capacity bags | Enhanced strength by bonding two paper layers |

As an example, some customers require very strong or large paper bags. For these, a machine that bonds two sheets of paper together before forming the bag can be ideal. This is mentioned by suppliers like Champion Machinery for their two-sheet paper pasting machine. We offer similar advanced solutions.

What about machines for paper bag handles?

Many paper bags need handles. This makes them much easier for customers to carry. So, how are these handles made and attached to the bags? Let's explore this part of the process.

Handle making machines create different styles of handles. Common types are twisted rope handles or flat paper handles. These handles are then attached to the paper bags. This can happen inline by the main bag machine or by a separate handle pasting machine.

Handles add a lot of function and appeal to paper bags. They make the bags more convenient for end-users. At BagMec®, we provide reliable solutions for producing various types of handles and attaching them securely.

Types of Handles and Their Machines

Different bag styles and uses call for different handle types. Here are a few common ones:

- Twisted Rope Handle Machines: These units make handles that look like a soft rope. They take paper ropes (which can be pre-made or made inline from paper strips). The machine cuts these ropes to the correct length. It then attaches a small piece of paper, called a patch, to each end of the handle. This patch is what gets glued to the bag. Our NEW WORLD A Series includes machines that can make and attach twisted handles online [allwell-paper.en.made-in-china.com/].

- Flat Paper Handle Machines: These machines create flat loop handles. They use rolls of paper. The paper is folded multiple times to make a strong, flat strap. These are very popular for retail shopping bags and food takeaway bags. Our Loop Handle Bag Making Machines ($33,000.00-$38,000.00) are specifically designed for producing these handles and bags.

- D-Cut (Patch Handle) Machines: These are not separate handles attached to the bag. Instead, they are cut-outs in the top part of the bag itself. To make them strong enough to carry, a patch of plastic film or thicker paper is applied around the cut-out area. This reinforces the handle. Our Patch Handle Bag Making Machines ($8,500.00-$15,500.00) create these integrated handles.

Handle Attachment Process

The way handles are attached can vary depending on the production setup:

- Inline Attachment: Many of our advanced BagMec® paper bag machines can make the handles and attach them to the bag bodies in one single, continuous process. This is highly efficient. It is best for high-volume production of handled bags.

- Offline/Semi-Automatic Attachment: For smaller production runs or for highly specialized bags, handles can be made separately by a handle making machine. Then, these pre-made handles are attached to already formed bags. This can be done manually or using a semi-automatic handle pasting machine.

We aim to offer flexible solutions. This allows you to choose the best method that fits your specific production volume and bag design requirements.

How is printing incorporated into paper bag manufacturing?

Branding is very important for paper bags. They act as walking advertisements. So, how do your logos, designs, and messages get onto these bags? Printing machines play a crucial role in this.

Printing on paper bags is most often done using flexographic (flexo) printing machines. This printing can happen in two main ways: either on the large paper roll before it's made into bags (pre-print), or on the formed bags themselves (post-print), depending on the machine configuration.

Printed paper bags are excellent marketing tools. At BagMec®, we understand that high-quality printing is vital for your brand's image. We ensure our machines facilitate this.

Flexographic Printing Explained

Flexographic printing, or flexo, is the industry standard for printing on paper bags. Here’s why:

- It uses flexible printing plates made of rubber or photopolymer. These plates transfer ink to the paper.

- It works very well with fast-drying inks. This is important for high-speed production.

- Flexo can print on many types of paper used for bags.

- It can print multiple colors, from simple one-color logos to complex, multi-color graphics.

Printing Integration Options

There are different ways to integrate printing into your paper bag production line:

- Inline Printing Units: Many of our BagMec® paper bag machines can be equipped with inline flexo printing units. This means the paper roll is printed just before it enters the bag forming section of the machine. This is very efficient. It combines printing and bag making into one smooth, continuous operation. These inline units commonly offer 2, 4, or even 6 color printing capabilities.

- Standalone Printing Machines (Pre-Print): For very high-resolution graphics or extremely large print jobs, some businesses choose to print the paper rolls separately. They might use a standalone CI (Central Impression) flexo press or a stack-type flexo press for this. After printing, these pre-printed rolls are then loaded onto the paper bag making machine.

We can help you decide the best approach. This depends on your desired print quality, design complexity, and production volume. For example, one of our clients, an Indian logistics giant, needed integrated QR code printing on their courier bags. We customized their heavy-duty bag production line to include this specific printing feature.

Considerations for Printing

When thinking about printing, keep these points in mind:

- Ink Types: Our machines are compatible with various ink types. This includes water-based inks, which are often preferred for food packaging or for more eco-friendly bagging solutions.

- Registration Accuracy: Our printing units are engineered for precise color registration. This means each color in your design aligns perfectly with the others. This results in a sharp, clear, and professional-looking print.

- Speed: Inline printing units are designed to work at the same speed as the bag making process. This ensures there are no bottlenecks in your production line.

What other specialized machines or features are important?

Beyond the basic forming, handle attachment, and printing, what else should you know about modern paper bag production? Certain specialized machines and advanced features can greatly enhance the process.

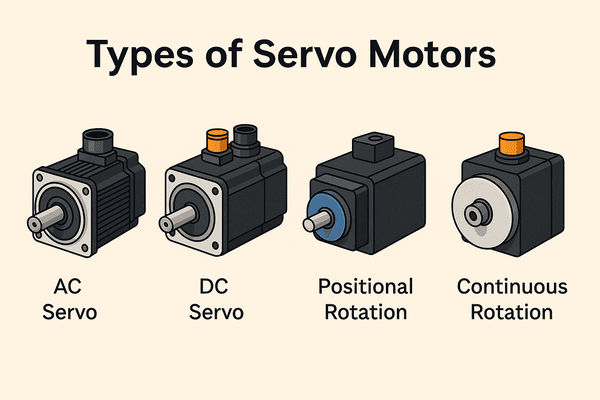

Specialized machines might create features like gussets for extra capacity, windows for product visibility, or unique closures. Key machine features like PLC controls for automation, energy-saving servo motors, and precise tension control systems also boost production quality and efficiency.

At BagMec®, we focus on incorporating advanced technology into our machines. This helps you produce top-quality paper bags efficiently and reliably, giving you a competitive edge.

Key Machine Components and Advanced Features

Modern paper bag machines come with several sophisticated components:

- PLC Control Systems: Most of our BagMec® machines feature Programmable Logic Controller (PLC) systems. These are like the brain of the machine. They automate and manage all operations. Operators can use a touchscreen interface, often available in multiple languages, to set parameters like bag length, speed, and glue application. This ensures precision and consistency.

- Servo Motors: We widely use energy-saving servo motors in our machine designs. These advanced motors can reduce power consumption by up to 30% compared to traditional motors. They also offer much better control and faster response times. This leads to higher quality bags and more consistent production speeds.

- "Smart Tension Control": This is a BagMec® patented technology that we are very proud of. It ensures the paper web feeds through the machine with perfectly consistent tension. Proper tension is vital. It prevents material stretching or tearing, reduces waste, and is key for accurate bag formation and printing.

- Automatic Web Guiding Systems: These systems continually monitor the position of the paper web as it moves through the machine. If the paper starts to drift to one side, the system automatically corrects its path. This is crucial for preventing misaligned prints, uneven folds, or poorly formed bags.

Specialized Bag Making Units and Capabilities

Depending on the type of paper bag you want to produce, you might need machines with specific units:

- Window Patching Units: For bags that allow customers to see the product inside (like for bread, cookies, or other food items), some machines can include a window patching unit. This unit cuts an opening in the bag and then securely glues a piece of clear film over it.

- Die-Cutting Units: For bags requiring unique shapes, special handle cut-outs, or decorative elements, precision die-cutting units can be integrated. These are often used for luxury retail bags or promotional bags.

- Gusset Formers: Side gussets are folds along the sides of a bag that allow it to expand and hold more volume. This is a common feature in square bottom shopping bags and grocery bags. Our machines have precise mechanisms to form these gussets accurately and consistently.

- Material Compatibility and Customization: Our machines are built to handle a variety of paper types and weights. We also have experience with eco-friendly materials like biodegradable PLA films for certain applications. This capability helped one of our US Eco-Brand clients. We co-developed machines with them to produce 100% compostable shopping bags. Additionally, as noted by sources like paper-bag-machine.com, some applications benefit from tube forming with multiple paper layers for extra strength, a capability we can integrate.

Conclusion

Making paper bags involves a set of specialized machines. From forming the bag body to adding handles and printing designs, each machine plays an important part. At BagMec®, we provide comprehensive and customized solutions to meet all your paper bag production requirements.