Are you tired of bags that rip easily? Maybe you're concerned if your packaging is safe for food, or strong enough for your products. Let's explore what really makes a plastic bag a good one.

A good plastic bag is durable and sturdy, always appropriate for its specific purpose. For food items, it means using food-grade plastics like PE or PP. When strength is vital, robust HDPE bags, often with a higher mil count, ensure top performance.

When we talk about a "good" plastic bag, it's more than just something to hold things. It’s about the material science. The plastic resin used, such as Low-Density Polyethylene (LDPE) or High-Density Polyethylene (HDPE), determines how flexible or tough the bag will be. Also, the bag's thickness, measured in mils or microns, is very important. A thicker bag generally means more strength and better resistance to punctures or tears. This makes sure the bag works as expected, whether it's for groceries, industrial components, or medical supplies.

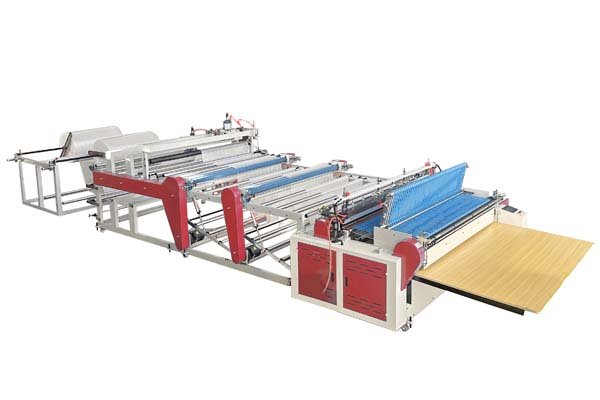

For example, a bag meant to hold sharp industrial parts needs high puncture resistance. This often comes from special material blends and increased thickness. Then, for food packaging, the plastic must be food-grade. This means it won’t transfer any harmful substances to the food. At BagMec®, our machines are engineered to precisely handle these diverse materials and critical specifications. This ensures the final bag our customers produce meets these essential quality standards every time.

How does material selection define plastic bag excellence?

Choosing the right plastic material is the very first step. This choice affects everything from how the bag feels in your hand to how well it protects what's inside.

Material excellence in a plastic bag comes from picking the correct resin, like flexible LDPE or strong HDPE. Additives can also improve features like UV protection or anti-static properties, tailoring the bag perfectly for its use.

Understanding Common Plastic Resins

The type of plastic resin is fundamental to a bag's characteristics.

- LDPE (Low-Density Polyethylene): This is perfect for bags that need to be soft and pliable. Think of produce bags or the bread bags made by our Wicketer Bread Bag Machines. LDPE offers good softness, flexibility, and decent clarity. It stretches well, which helps prevent tearing.

- HDPE (High-Density Polyethylene): When you need strength and stiffness, HDPE is the answer. Grocery store t-shirt bags or some types of garbage bags often use HDPE. It provides excellent moisture protection and can be made thinner than LDPE while still being quite strong. Our T-Shirt Bag Making Machines are built to process HDPE rapidly and reliably.

- PP (Polypropylene): PP gives great clarity and has a higher melting point. This makes it good for packaging items that might be warm or need to look very appealing on shelves. Snack food packaging often uses PP films.

- Laminates and Co-extrusions: For complex needs, like making sure food stays fresh longer or protecting contents from oxygen, different plastic layers are combined. Our Lamination Pouch Making Machines are experts at handling these advanced multi-layer films, ensuring each layer contributes to the bag's performance.

The Role of Additives

Additives are special ingredients that can significantly change how a bag performs.

- For example, UV inhibitors protect the bag's contents from sunlight damage.

- Slip agents make bags easier to open, which is important for packaging lines and end-users.

- Anti-static additives prevent static build-up, stopping dust from clinging to the bag.

- Color concentrates allow for branding and can make bags opaque for security.

- At BagMec®, our machines are designed to be versatile. They can work effectively with films that include various additives. We ensure our machine processes, like sealing and cutting, maintain the integrity of these specialized materials.

Material Thickness (Gauge/Mil)

The thickness of the plastic film is a critical factor for bag quality. It's often measured in "mils" (thousandths of an inch) or microns.

| Bag Type Example | Typical Material | Common Thickness Range (mil/micron approx.) | Why it Matters for Quality |

|---|---|---|---|

| Small Produce Bag | LDPE | 0.5 - 1.0 mil (12-25 microns) | Lightweight, cost-effective, good for light items |

| T-Shirt Shopping Bag | HDPE | 0.5 - 1.5 mil (12-38 microns) | Offers strength even when thin, economical |

| Heavy-Duty Garbage Bag | LDPE/HDPE Blend | 1.5 - 4.0 mil (38-100 microns) | Needs high puncture and tear resistance for waste |

| Courier/Mailer Bag | LDPE Co-ex | 2.0 - 3.5 mil (50-88 microns) | Requires durability, opacity, often tamper-evidence |

| Food Pouch (Laminated) | Various | 2.5 - 5.0 mil (63-125 microns) | Essential for barrier properties and freshness |

A good bag has the right thickness for its job. If it's too thin, it might fail. If it's too thick, it's wasteful and more expensive than necessary. Our BagMec® machines feature "Smart Tension Control." This patented technology is vital for consistently working with different film thicknesses, ensuring the film feeds smoothly, whether it's a delicate thin film or a robust heavy-duty one.

Why is manufacturing precision crucial for a top-quality bag?

Even the best materials won't make a good bag if it's poorly made or assembled. Manufacturing precision is where the material's potential turns into actual quality.

Manufacturing precision ensures every bag has consistent dimensions, strong seals, and correctly placed features like handles or zippers. This directly affects how reliable and functional the bag is, making it dependable for everyone who uses it.

The Importance of Sealing

The seal is often where a bag might fail if not made correctly.

- Seal Strength: A good seal must be strong enough to hold whatever the bag is designed for, without bursting or leaking. This strength depends on carefully controlled temperature, pressure, and the amount of time the seal is applied (dwell time). Our machines use advanced PLC control systems to manage these factors very precisely for different film types.

- Seal Consistency: It's not enough for one seal to be good; every seal on every bag must be consistent. Uneven or incomplete seals are a common cause of bag failure. We use high-quality heating elements and pressure systems in our machines to make sure seals are uniform across the entire width and from bag to bag.

- Types of Common Seals:

- Bottom Seal: Very common for flat bags or garbage bags. It creates a strong base.

- Side Seal (Side Weld): Often used for items like bread bags, produce bags, and some types of pouches. Our Side Sealing Bag Machines are designed to create clean, strong side welds.

- Star Seal: You might see this on some kitchen garbage bags. It's designed to spread stress more evenly and helps prevent leaks.

Our BagMec® machines are engineered for robust and consistent seals. This applies whether it’s a simple side seal or a complex seal needed for a zipper bag. Our "Smart Tension Control" system also helps here. It makes sure the film feeds smoothly and without wrinkles into the sealing section, which is essential for a perfect seal.

Cutting and Perforation Accuracy

How a bag is cut and perforated also says a lot about its quality.

- Clean Cuts: Bags need to be cut cleanly from the continuous roll of plastic film. Ragged or uneven edges are a sign of poor manufacturing and can sometimes be a weak point.

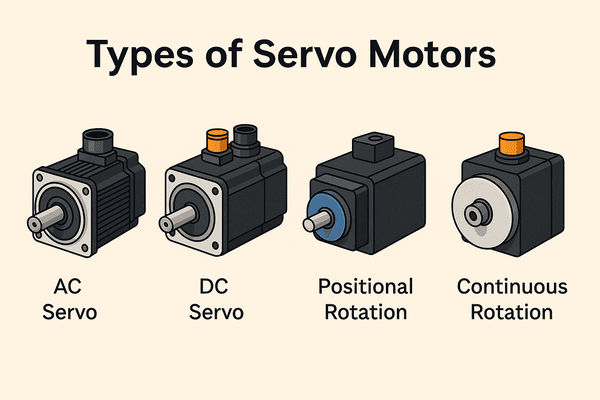

- Accurate Length: Each bag must be cut to the correct length, over and over again. Our machines use servo motor-driven systems. These ensure very high precision in controlling bag length, so you don't have variations.

- Perforations (for bags on a roll): If bags come on a roll (like garbage bags or produce bags), the perforations between them must be just right. They need to be strong enough so the roll doesn’t fall apart, but easy enough for a user to tear off one bag at a time cleanly.

Our various machines, like the T-Shirt Bag Making Machine or the Garbage Bag Machine, include high-Precision cutting units designed for millions of cycles.

Feature Integration

Many modern bags have added features. Precision here is absolutely key to their function.

- Handle Placement and Attachment: For shopping bags (like those made on our Loop Handle Bag Making Machine) or patch handle bags (from our Patch Handle Bag Making Machine), the handles must be securely attached and positioned correctly and uniformly. A poorly attached handle means the bag fails.

- Zipper Alignment: On zipper bags, the zipper strip must be perfectly aligned with the bag edges and sealed properly along its entire length. If not, the zipper won’t close right or might leak. Our Zipper Bag Making Machines are built specifically for this kind of precision.

- Specialty Features: Some bags require unique elements, like the paper holders and ultrasonic welding found in specialized machines like those for dust vacuum cleaner bags ncm-machinery.com. Our machines, such as the Courier Bag Machine used by our Indian logistics client to produce 2,500 bags/hour, can integrate features like tear-resistant seams or precise placement for address windows.

At BagMec®, our 5-stage inspection protocol for every machine is very strict. It includes precision alignment verification using laser calibration. We also run a 72-hour continuous operation stress test. This ensures that every machine we ship can deliver this essential manufacturing precision, which then translates directly to the superior quality of the bags our customers produce.

Can eco-friendly plastic bags truly be "good" bags?

Many people ask if "eco-friendly" and "good quality" can exist together in plastic bags. My answer is a strong yes, especially with today's technology and materials.

Yes, eco-friendly plastic bags can be excellent. A "good" eco-friendly bag performs its main job effectively and helps reduce environmental impact. This can be through biodegradability, compostability, or using recycled content, without losing necessary strength or safety.

The idea of a "good" bag is definitely changing to include environmental responsibility. At BagMec®, we are fully committed to supporting this important shift in the industry. Some companies, like one mentioned by nova-mech.com, moved into non-woven bag making due to concerns about "white pollution," showing a long-standing industry awareness.

Types of Eco-Friendly Plastics

- Recycled Content Bags:

- These bags are made partly or wholly from post-consumer recycled (PCR) or post-industrial recycled (PIR) plastics.

- Benefit: This reduces waste going to landfills, conserves new (virgin) resources, and usually lowers the carbon footprint of the bag.

- Challenge: Sometimes, ensuring consistent strength and appearance can be tricky with recycled content. But, new advances in plastic recycling and processing are constantly improving the quality. Our BagMec® machines are increasingly designed to effectively handle films with higher percentages of recycled material.

- Biodegradable/Compostable Bags (e.g., PLA, PHA, Starch-based):

- These are often made from plant-based materials (like corn starch or sugarcane for PLA) or other special polymers. These polymers are designed to break down into natural components under specific composting conditions.

- Benefit: If composted properly in industrial facilities, they can reduce the amount of persistent plastic in the environment.

- Challenge: They usually need specific industrial composting facilities to break down effectively; home composting might not always work. Also, these bioplastics might have different performance characteristics (like a shorter shelf life or more sensitivity to heat) compared to traditional plastics.

- We are proud to have co-developed machines for biodegradable PLA film. This has enabled clients, like a US Eco-Brand we worked with, to produce 100% compostable shopping bags for zero-waste retail.

Machine Adaptability for Eco-Materials

Processing these eco-friendly materials can sometimes require different machine settings or even specialized components.

- Temperature Sensitivity: Some bioplastics, like PLA, are more sensitive to heat than traditional plastics like PE. So, the sealing temperature, pressure, and time must be controlled very accurately. Our BagMec® machines offer this precise temperature control, which is crucial for working with these materials.

- Film Strength and Behavior: Films made from recycled material or bio-based content might stretch differently or have different tensile strengths. Our patented "Smart Tension Control" system is a big advantage here. It can adapt to these varying film properties, ensuring smooth feeding and processing.

- At BagMec®, we focus on making our machines versatile. Our commitment to sustainability means we are always researching and developing ways to optimize our equipment for recycled and biodegradable materials. This helps our customers produce high-quality bags that are also friendlier to the environment. Our energy-saving servo motors, reducing power consumption by up to 30%, also contribute to a more sustainable production process.

Balancing Performance and Eco-Friendliness

A "good" eco-friendly bag must still do its main job well. A compostable grocery bag that tears before you get home is not a good bag, no matter how eco-friendly it is.

The key is to find the right balance:

- Right material for the application: A heavy-duty compostable bag designed for collecting organic waste needs different properties than a lightweight biodegradable produce bag.

- Clarity on disposal: It’s important for users to understand how to dispose of these bags correctly (e.g., recycling bin, industrial compost facility) to actually get the environmental benefits.

Our role at BagMec® is to provide the machinery that lets manufacturers produce these types of bags reliably, efficiently, and with the quality that end-users expect.

How do different industries define a "good" plastic bag?

A company selling fresh food has very different bag needs than a company shipping clothes. What makes a bag "good" truly depends on who is using it and for what purpose.

Different industries prioritize different bag qualities. For food packaging, safety and freshness (barrier properties) are top priorities. But for courier bags or heavy-duty industrial uses, strength and tear resistance are most vital.

The specific requirements for a "good" plastic bag change a lot based on its final application. At BagMec®, we understand these differences. That's why we build a diverse range of machines, from those making T-Shirt bags (priced around $17,000-$32,000) to complex Wicketer Bread Bag Machines (around $69,000-$88,000), each designed to cater to specific industry needs.

Retail Industry

- Key Priorities: Good carrying strength for purchased goods, cost-effectiveness for bulk use, branding opportunities (good printability), and ease of use for customers (e.g., T-shirt bags, loop handle bags).

- BagMec® Solution: Our high-speed shopping bag machines (like the T-Shirt Bag and Loop Handle Bag machines) are designed for efficient production of durable bags. They can produce up to 1,200 bags/hour for certain types, ensuring strong handles and options for customization.

Food Packaging Industry

- Key Priorities: Absolute food safety (using FDA-compliant materials like PE and PP), good barrier properties (to keep food fresh and protect from contamination), strong seal integrity (to prevent leaks), often clarity (so customers can see the product), and sometimes suitability for freezer or microwave use.

- BagMec® Solution: Our food-grade packaging machines (including Zipper Bag, Side-Seal Bag, Form-Fill-Seal (FFS) Bag, and Lamination Pouch machines, with prices for food packaging machines generally between $30,000-$68,000) are designed with anti-contamination features. They handle materials suited for direct food contact and ensure reliable, strong seals, critical for food safety as a German packaging supplier using our FFS machines found, achieving 99% uptime.

Logistics and E-commerce Industry

- Key Priorities: High durability, strong tear resistance, good puncture resistance (to withstand rough handling), tamper-evidence (for security), opacity (to hide contents), and sometimes weather resistance.

- BagMec® Solution: Our Courier Bag Machines (often priced $23,000-$35,000) and Heavy-Duty Bag Machines produce bags with reinforced, tear-resistant seams. They are built to handle the tough demands of shipping. An Indian logistics giant uses our customized courier bag line, producing 2,500 bags/hour with integrated QR code printing.

Medical and Hygiene Industry

- Key Priorities: Sterility or high levels of cleanliness, material safety (non-toxic and non-reactive), secure closures, and compliance with specific industry standards (e.g., ISO standards for certain medical device packaging).

- BagMec® Solution: Our Diaper Bag Making Machines (typically $25,000-$70,000) and other specialized systems can be adapted for medical and hygiene applications. We focus on clean production environments and ensuring material compatibility. We can develop solutions like aseptic diaper bag production lines, addressing needs like those of Carlos Mendez, a Production Head in Mexico looking for ISO 13485 compliance.

Industrial Applications

- Key Priorities: Extreme strength for very heavy or abrasive contents (like construction materials or aggregates), chemical resistance (if storing chemicals), and large capacity.

- BagMec® Solution: Our Heavy-Duty Bag Machines (priced $12,000-$23,000) can produce very strong bags from thick films. These are designed to hold items like building materials, certain chemicals (when using the correct resistant film materials), or bulk agricultural products.

Quick Comparison of Industry Needs:

| Industry | Key Attribute 1 | Key Attribute 2 | Key Attribute 3 | BagMec® Machine Example(s) |

|---|---|---|---|---|

| Retail | Carry Strength | Cost-Effectiveness | Printability/Branding | T-Shirt Bag Machine, Loop Handle Bag Machine |

| Food Packaging | Food Safety (FDA Grade) | Seal Integrity | Barrier Properties | Food Package Bag Machine, Zipper Bag Making Machine |

| E-commerce/Logistics | Tear Resistance | Puncture Resistance | Security (Opacity/Tamper) | Courier Bag Machine, Heavy Duty Bag Machine |

| Medical/Hygiene | Cleanliness/Sterility | Material Safety | Secure Closure | Diaper Bag Making Machine |

| Industrial Applications | Heavy-Duty Strength | Chemical Resistance | Large Volume Capacity | Heavy Duty Bag Machine |

Understanding these very different requirements allows us at BagMec® to design and manufacture specialized machinery. Our goal is to ensure that each machine delivers precisely what each specific industry considers a "good" quality bag.

Conclusion

In the end, a good plastic bag is strong, made from the right material, and perfectly fits its intended purpose. Quality manufacturing, like we strive for at BagMec®, ensures it performs reliably every single time.