Trying to find out how much a garbage bag machine1 costs can be tough. You might see a wide range of prices, or no prices at all. This makes it hard to plan your budget. I'm here to help clear things up.

A garbage bag machine from us at BagMec® typically costs between $23,000 and $35,000. This price can change based on the specific features and capabilities you need for your production.

That price range gives you a good starting point. But, the final cost isn't just a simple number pulled out of thin air. It really depends on what the machine can do. Think about things like how many bags it can make per minute, how much of the process is automated, and what kind of plastic films it can handle. At BagMec®, we have machines in this range that we can customize to fit exactly what your business needs. We focus on giving you a machine that offers great value and performance.

So, what exactly influences that price tag? Several factors come into play.

- Machine Complexity: A basic machine that makes simple bottom-sealed bags will cost less than one that can produce bags with drawstrings or star seals. More complex features mean more engineering and parts.

- Production Capacity: If you need to make a lot of bags very quickly, you'll need a machine with higher output. Faster machines usually have more advanced motors and control systems, which adds to the cost.

- Automation Level: A semi-automatic machine requires more operator involvement, while a fully automated system with PLC controls and touchscreen interfaces will be more expensive but can reduce labor costs and increase efficiency.

- Custom Features: Do you need an inline printing unit for logos? Or maybe a special folding device? These kinds of add-ons will also affect the final price.

How Do Specific Machine Features Affect Garbage Bag Machine Prices?

You might see two garbage bag machines and wonder why one costs more than the other. Well, it's usually down to the specific features and technology packed into them.

Key features like advanced sealing types, the level of automation, production speed, and custom add-ons significantly impact the final price of a garbage bag machine. More sophisticated features generally mean a higher investment.

Let's take a closer look at how these features can change the price. It's not just about having more buttons; it's about what those features can do for your production line and the quality of your bags.

Breaking Down Feature Costs

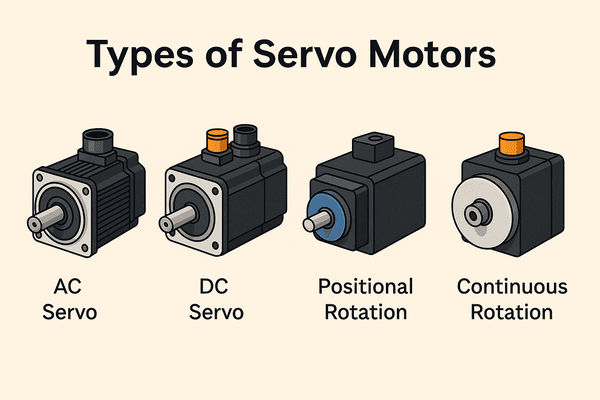

Automation Levels and Their Cost Implications

Automation is a big factor. A machine that does more on its own costs more upfront. But, it can save you money on labor and errors in the long run.

For example, our BagMec® machines can range from semi-automatic, needing more hands-on work, to fully automated systems. These fully automated systems use PLC controls and smart servo motors, like our "Smart Tension Control" technology, which ensures consistent film feeding. This technology adds to the price but boosts your output and quality.

| Feature | Semi-Automatic Machine | Fully-Automated Machine | Cost Impact |

|---|---|---|---|

| Labor Needed | Higher | Lower | Significant |

| Consistency | Depends on operator skill | Very High | Medium |

| Initial Cost | Lower | Higher | High |

| Output Speed | Moderate | High | High |

| Complexity | Simpler mechanics | Advanced PLC, Servos | High |

Sealing Technology and Its Price Point

The type of seal your garbage bags need also affects the price.

- Bottom Seal: This is the most common and usually the most cost-effective sealing method. It's great for standard trash bags.

- Side Seal: This is often used for stronger bags or bags that need a particular shape. The machinery can be a bit more complex.

- Star Seal: These seals are very strong and help the bag conform to the shape of a trash can. The mechanism to create a star seal is more specialized, adding to the cost.

- Drawstring/Tape Unit: If you want bags with drawstrings, the machine needs an extra unit to insert and seal the tape. This is a significant add-on and increases the price.

Machines that can do multiple types of seals or more complex seals will naturally be more expensive.

Production Speed and Output

How many bags do you need to make per minute or per hour? A machine designed for high-speed production (e.g., 200+ bags/minute) will have more robust components, precision engineering, and more powerful motors than a machine that produces, say, 100 bags/minute. This increased capability directly translates to a higher price. Our high-speed machines are built for reliability even at top speeds, ensuring you get the output you pay for.

Custom Add-ons: Printing, Folding, and More

Many businesses need more than just a plain bag.

- Printing Units: If you want to print logos, instructions, or branding on your bags, an inline flexographic printing unit can be integrated. The number of colors and printing width will affect this additional cost.

- Folding Units: Some machines can automatically fold the bags into specific configurations (e.g., C-fold, Z-fold) or perforate them for rolls. This adds mechanical complexity and cost.

- Special Material Handling: If you're using very thin films, recycled materials, or biodegradable plastics like PLA, the machine might need special tension controls or temperature regulators. Our BagMec® machines are designed to handle various materials, including LDPE/HDPE/PP films and biodegradable PLA, thanks to features like our "Smart Tension Control."

Are Cheaper Garbage Bag Machines a Good Investment?

It's natural to want to save money. So, a cheaper garbage bag machine might look like a great deal at first. But you need to think about the long run.

Cheaper garbage bag machines can have a lower initial cost. But, they often come with trade-offs like lower build quality, less durability, reduced efficiency, and potentially higher maintenance costs over time.

Saving money upfront is good. But if the machine breaks down often, produces a lot of waste, or doesn't last very long, those initial savings can disappear quickly. It's about finding the right balance between cost and quality.

The Real Cost of "Cheap"

The Hidden Costs of Low-Priced Machines

A low price tag can hide several potential problems:

- Increased Downtime: Cheaper machines might use lower-quality components that wear out faster. This means more time when your machine isn't running and you're not making money.

- Higher Maintenance Bills: More frequent repairs and part replacements add up.

- Material Waste: If the machine isn't precise, it might produce more faulty bags. This wastes your raw materials and cuts into your profits.

- Shorter Lifespan: A less durable machine will need to be replaced sooner. This means another big investment down the line.

- Lower Efficiency: They might consume more energy or require more manual labor, increasing your operational costs. This is something Hans Fischer from Germany might be wary of, given his concern for EU standards which often include energy efficiency.

Quality vs. Price: Finding the Balance with BagMec®

At BagMec®, we believe in providing value, not just a low price. Our machines, even in the $23,000-$35,000 range for garbage bag machines, are built with quality in mind.

We use high-carbon steel components for durability. Our machines often feature energy-saving servo motors, which can reduce power consumption by up to 30%. This is a long-term saving. We also adhere to ISO 9001 Quality Management and CE Compliance. This focus on quality means our machines are built to last and perform efficiently, giving you a better return on your investment.

When a Basic, More Affordable Machine Might Be Enough

Sometimes, a simpler, less expensive machine is the right choice.

If you are a startup like Priya Kapoor in India, who might be looking for a compact and budget-friendly solution, a basic machine with fewer bells and whistles could be perfect to get started. If your production volume is low, or you only need to make one specific type of simple bag, you might not need all the advanced features. We can help you figure out if a more standard model meets your needs without overspending.

What's Included in the BagMec® Garbage Bag Machine Price?

When you look at our price for a garbage bag machine, you might wonder what exactly you get for that money. We believe in being clear about what's included.

Our BagMec® garbage bag machine price, typically from $23,000 to $35,000, covers the fully assembled machine with standard features like PLC controls, quality motors, and essential safety mechanisms, ready for production.

Beyond the physical machine, we aim to provide a solid foundation for your bag-making operations. We want you to feel confident in your purchase.

Unpacking the Value

Standard Inclusions in Our Machines

When you invest in a BagMec® garbage bag machine, you generally receive:

- The Core Machine: Fully assembled and tested according to our 5-stage inspection protocol, which includes a 72-hour continuous operation stress test.

- Control System: Typically a PLC (Programmable Logic Controller) with a user-friendly touchscreen interface, often available in multiple languages.

- Drive System: Efficient motors, often servo motors for precision and energy saving (like our documented 30% reduced power consumption).

- Standard Sealing and Cutting Unit: Designed for the bag types specified.

- Basic Toolkit: For routine adjustments and maintenance.

- Safety Features: Emergency stop buttons and safety guards compliant with CE standards.

- Documentation: User manuals and technical specifications.

Optional Add-ons and Services

To further enhance your machine or support your operations, we offer optional services and components. These are not usually in the base price but can be added:

- Specialized Parts: Such as particular die-cutters, embossing units, or advanced stacking systems.

- On-site Installation & Training: Our technicians can come to your facility to set up the machine and train your team. This helps you get up and running smoothly. (This addresses concerns like Priya Kapoor's about limited technical support from other vendors).

- Spare Parts Packages: For common wear-and-tear items.

- Extended Warranty Options.

- Customization for specific materials or bag designs.

We discuss these options with you to ensure you only pay for what you truly need.

Understanding Total Cost of Ownership (TCO)

We encourage you to think about the Total Cost of Ownership, not just the purchase price. A slightly more expensive machine might save you money over its lifetime.

Factors contributing to a lower TCO with BagMec® machines include:

- Energy Efficiency: Our energy-saving servo motors directly reduce your electricity bills.

- Durability: High-carbon steel components and corrosion-resistant coatings (especially useful in humid environments) mean our machines last longer and need fewer major repairs.

- Reduced Waste: Precision engineering, like our "Smart Tension Control," minimizes material waste.

- Predictive Maintenance Capabilities: Some of our future-ready machines are IoT-enabled for remote diagnostics, helping prevent costly unexpected downtime.

How Can I Get an Accurate Quote for a Garbage Bag Machine?

Now that you know more about the costs and features, you probably want a specific price for your needs. Getting an accurate quote is straightforward if you provide the right information.

To get an accurate garbage bag machine quote, tell us your specific requirements. This includes the type and size of bags you want to make, the material, your desired production speed, and any special features.

The more details you can give us, the better we can tailor a machine and a quote for you. Generic price lists often don't capture the nuances of custom manufacturing.

Your Path to a Precise Quote

Key Information We Need From You

To help us prepare the most accurate quote, please try to provide the following:

- Bag Type: Are they bottom-sealed, side-sealed, star-sealed, on a roll, with drawstrings?

- Bag Material: LDPE, HDPE, PP, recycled, biodegradable (like PLA)? What's the film thickness?

- Bag Dimensions: Width, length, and gusset size (if any).

- Production Capacity: How many bags do you need per minute or per hour?

- Automation Level: Are you looking for a semi-automatic or fully automated line?

- Special Features: Do you need printing, folding, hole punching, or specific conveying systems?

- Your Location: For shipping cost estimation and service considerations.

Don't worry if you're unsure about some of these. We can discuss your project and help you figure out the best specifications. This is especially true if you have specific needs like Carlos Mendez, who requires an aseptic machine, highlighting how detailed needs shape machine design.

Our Quoting Process at BagMec®

Here’s how we typically work to get you a quote:

- Initial Contact: Reach out to us via email (info@bagmec.com) or our website.

- Consultation: We'll discuss your needs. This might be a call or email exchange. We want to understand your project thoroughly – your current challenges and future goals.

- Needs Assessment & Machine Configuration: Based on your input, our engineers will recommend the best machine configuration or suggest custom solutions.

- Quote Preparation: We calculate the costs, including any chosen options or services.

- Quote Delivery: We aim to deliver a detailed quote within 48 hours. This quote will outline the machine specifications, price, payment terms, and estimated delivery time.

You can even request a free engineering consultation or schedule a virtual factory tour to see our capabilities firsthand.

Why Generic Price Lists Can Be Misleading for Industrial Machinery

You might wonder why we don't just publish a fixed price list.

The truth is, most industrial machines, especially in a specialized field like bag making, are not "one-size-fits-all."

- Customization: Many clients need specific modifications to meet their unique production environment or product requirements. A standard list can't cover all these variations.

- Varying Input Costs: Material and component costs can fluctuate.

- Shipping and Installation: These costs vary greatly depending on location and the complexity of the setup.

By providing a custom quote, we ensure the price you receive accurately reflects the machine and services that will best serve your business.

Conclusion: Understanding Your Garbage Bag Machine Investment

So, the cost of a garbage bag machine, around $23,000 to $35,000 from us at BagMec®, depends on its features, speed, and automation. We focus on quality and clear pricing to give you the best value for your specific needs.

-

Understanding the average cost can help you budget effectively for your business needs. ↩