Are you worried about plastic bag bans1 affecting your business? Many places are talking about new rules. We'll explore what's really happening with plastic bag laws around the world.

Some countries and regions are banning or taxing certain plastic bags, especially thin, single-use ones. However, a complete global ban is not happening soon. Many developing nations still heavily rely on plastic bags for daily use.

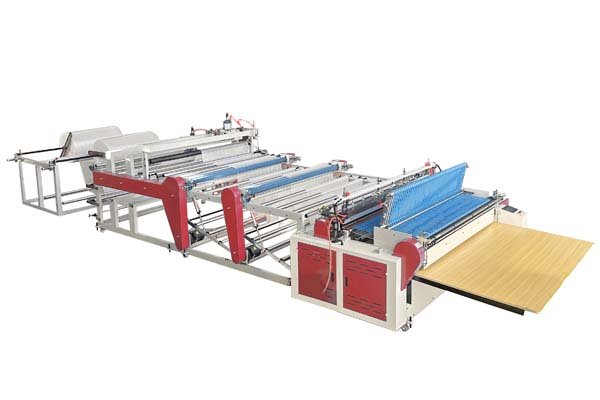

This topic is on many people's minds. We see headlines about plastic bag bans in places like the European Union, Canada, and several U.S. states. These rules often target the lightweight carrier bags you get at checkout. But, the story is different in many other parts of the world. In numerous developing countries, plastic bags are an affordable and practical solution for many people and businesses. So, the global picture is quite mixed. As a bag-making machine manufacturer, we at BagMec® keep a close eye on these trends to help our clients.

For example, some developed nations like France have had strong restrictions for years. They aim to encourage reusable bags2 or charge fees for new plastic ones. Kenya also has one of the strictest bans on plastic carrier bags. On the other hand, many developing economies face big challenges. The cost of alternatives, existing manufacturing jobs, and the lack of widespread recycling infrastructure make quick bans very difficult. It's a situation with many different sides to it.

What types of plastic bags face restrictions most often?

You might be wondering if all plastic bags are treated the same under these new rules. Let's look closer at what kinds of bags are usually affected.

Thin, single-use plastic carrier bags, typically those less than 50 microns thick, are the most common targets for bans or fees. Heavier, reusable plastic bags or specialized industrial bags are often exempt or have different rules.

When we dive deeper into these regulations, we see specific patterns.

Lightweight Carrier Bags Take the Hit

Most regulations focus on the very thin plastic bags given out at supermarkets or retail stores. These are often called T-shirt bags or shopping bags.

- Reason: They are easily littered and contribute significantly to visible pollution.

- Material: Usually made from HDPE (High-Density Polyethylene) or LDPE (Low-Density Polyethylene).

Why These Specific Bags?

The main goal is to reduce plastic waste that escapes collection systems and harms the environment. These lightweight bags are particularly problematic because:

- They have a short usage life.

- Their light weight allows them to travel easily by wind and water.

- They often lack economic value for recyclers.

Exemptions and Nuances

It's important to note that not all plastic bags fall under these bans.

- Thicker, "reusable" plastic bags: Some laws allow for thicker plastic bags, designed for multiple uses, sometimes with a fee.

- Bags for specific purposes: Bags used for wrapping fresh produce, meat, or fish for hygiene reasons are often exempt. Bags for bulk items, pharmacy prescriptions, or garbage collection might also have different rules.

- Industrial packaging: Bags used in industrial processes or for heavy-duty applications (like our heavy-duty bag machines produce) are generally not part of these consumer-focused bans.

Here's a simple table to illustrate:

| Bag Type | Common Regulatory Status | Typical Material | Our Machine Focus (BagMec®) |

|---|---|---|---|

| Thin single-use carrier bags | Often banned or taxed | HDPE, LDPE | T-Shirt Bag Machine, Patch Handle (if thicker) |

| Thicker reusable plastic bags | Sometimes allowed, often w/ fee | LDPE, PP | Loop Handle Bag Machine, Shopping Bag Machines |

| Produce/Meat bags (primary) | Usually exempt | LDPE | Side Sealing Bag Machine (for some types) |

| Garbage/Bin liners | Varies, can be regulated | LDPE, Recycled | Garbage Bag Machine |

| Courier / E-commerce bags | Generally not consumer banned | LDPE, Co-ex | Courier Bag Machine |

| Industrial / FFS Bags | Generally not consumer banned | PE, PP, Laminates | Heavy Duty Bag Machine, FFS Bag Machine |

Understanding these distinctions is key for businesses to adapt. At BagMec®, we offer machines like our T-Shirt Bag Making Machine for standard bags, but also solutions for thicker, more durable options, and specialized bags that meet new demands.

What are businesses using instead of banned plastic bags?

If some plastic bags are restricted, what are the alternatives businesses are adopting? Let's explore the common substitutes.

Businesses are increasingly using reusable bags (like cloth or PP non-woven), paper bags, and compostable or biodegradable "plastic" bags. The best choice depends on the product, cost, local regulations, and consumer acceptance.

The shift away from conventional thin plastic bags has spurred innovation and a return to older methods.

Reusable Bags

These are designed for multiple uses and are becoming very popular.

- Materials: Cotton, canvas, jute, PP (polypropylene) non-woven, or durable, thick plastic.

- Pros: Strong, can be branded, reduces the number of single-use bags.

- Cons: Higher upfront cost, consumers need to remember to bring them.

- Our Angle: We at BagMec® manufacture Loop Handle Bag Making Machines and Patch Handle Bag Making Machines, which can produce durable PP non-woven bags or thicker PE bags intended for reuse.

Paper Bags

A classic alternative that many are returning to.

- Pros: Often recyclable and biodegradable (if not coated with plastic). Can have a premium feel.

- Cons: Less durable than plastic, especially if wet. Higher production footprint (water and energy) than some plastics. Can be more expensive.

Compostable and Biodegradable Bags

These are designed to break down under specific conditions.

- Materials: PLA (polylactic acid), PHA (polyhydroxyalkanoates), starch-based polymers.

- Pros: Can reduce plastic accumulation if properly composted. Made from renewable resources (for some types like PLA).

- Cons: Require industrial composting facilities (not always available). Can contaminate conventional plastic recycling streams if mixed. "Biodegradable" can be misleading if conditions aren't met.

- Our Angle: Our expertise at BagMec® includes machinery compatible with biodegradable PLA films. We've even co-developed machines for 100% compostable shopping bags with eco-brands. Our "Smart Tension Control" technology is excellent for handling these sometimes delicate films.

Other Plastic Formulations

Sometimes, the shift is not away from plastic entirely but towards different types or thicker gauges.

- Recycled content plastic bags: Mandated in some areas to promote circular economy.

- Thicker PE bags: As mentioned, to encourage reuse.

The key is finding an alternative that works for your product, your customers, and the local rules. At BagMec®, our machines for food packaging, laminated pouches, and side-seal bags can often be adapted for new film types, offering flexibility.

How can my business adapt to changing plastic bag regulations?

Regulations about plastic bags can change. So, how can your business prepare and adapt effectively? Here are some practical steps.

To adapt, first, you must stay informed about local and regional laws. Then, evaluate your current bag usage and explore suitable alternative materials or bag designs. Investing in versatile machinery, like ours at BagMec®, allows for flexible production adjustments.

Navigating this changing landscape requires a proactive approach.

1. Stay Informed

Regulations vary widely by country, state, or even city.

- Action: Regularly check government environmental agency websites and industry news. Understand the specifics: what types of bags are restricted? What are the thickness limits? Are there fees or outright bans?

2. Assess Your Current Needs

Understand exactly how you use plastic bags.

- Action: What products do they carry? What strength is needed? What is the customer expectation? This helps identify where changes will have the most impact.

3. Explore Alternative Materials and Designs

Look into the options discussed earlier – reusable, paper, compostable, or different plastic types.

- Action: Consider cost, performance, supply chain, and customer perception for each alternative. For example, if you're in food packaging, our food-grade packaging machines can handle various films, including laminates or barrier films that might still be perfectly acceptable and necessary. If you need courier bags, their specific function typically keeps them outside common carrier bag bans; our DHL Multifunction Bag Making Machine handles these robust bags.

4. Partner with a Flexible Machinery Provider

This is where we come in. Your machinery needs to be adaptable.

- Action: Choose machines that can handle different materials (LDPE/HDPE/PP films, biodegradable PLA, multi-layer laminates) or can be modified.

- BagMec® Advantage: Our machines offer various automation levels and custom features. For example, our "Smart Tension Control" is vital for consistently feeding different film types. We offer specialized machines like Wicketer bread bag machines, which have very specific requirements, or lamination pouch making machines for high-value packaging. Our flexibility means we can help you pivot. We even accept prototype orders (1 machine) before you scale up.

5. Communicate with Your Customers

Let your customers know about any changes you're making and why.

- Action: This can be an opportunity to highlight your commitment to sustainability or compliance.

Adapting isn't just about avoiding penalties; it's about future-proofing your operations. Our team at BagMec® provides engineering consultations to help you find the right machine solution for your evolving needs.

Why isn't there a worldwide ban on all plastic bags yet?

With growing environmental concerns, many ask why a single, global ban on all plastic bags hasn't happened. The reasons are complex and varied.

A global ban is difficult due to vast economic differences between countries, varying levels of waste management infrastructure, the essential roles plastic bags still play in many sectors, and the lack of universally perfect and affordable alternatives.

Economic Factors and Development Levels

- Cost: For many developing countries, plastic bags are the cheapest and most readily available option for consumers and small businesses. Alternatives can be significantly more expensive.

- Industry & Jobs: The plastic manufacturing and بغ (bag) production industries employ many people globally. Abrupt, sweeping bans without viable economic transitions would lead to job losses.

Infrastructure Gaps

- Waste Management: Effective bans often need robust waste collection, sorting, and recycling or composting infrastructure. Many regions lack this. Without it, even "better" alternatives can end up as litter or in landfills.

- Production of Alternatives: Shifting to alternatives requires new manufacturing capabilities, supply chains, and technologies, which take time and investment to establish globally.

Essential Uses and Lack of Perfect Alternatives

- Hygiene and Food Safety: In many applications, like packaging fresh food or medical supplies, plastic bags provide critical hygiene and preservation functions that are hard to replace cheaply and effectively. Our food package bag machines and diaper bag machines cater to these vital needs.

- Performance: Plastic bags are lightweight, strong, and water-resistant. Finding a single alternative that matches all these properties at a similar cost is challenging.

Varying National Priorities and Capacities

- Sovereignty: Each country sets its own environmental and economic priorities based on its unique situation. International agreements on such issues are complex to negotiate and enforce.

- Enforcement: Even where bans exist, enforcement can be inconsistent due to limited resources or local resistance.

While a total global ban isn't on the immediate horizon, the trend is towards more regulation and a search for sustainable solutions. This means businesses need reliable partners like BagMec® to provide machinery for compliant and efficient bag production, whether it's for traditional PE bags in regions without bans, or for newer biodegradable materials and specialized bags elsewhere.

Conclusion: Navigating the Future of Bags

Plastic bag regulations are evolving globally, with more restrictions on some types. However, demand continues in many areas. Businesses must stay informed and adapt. BagMec® offers a wide range of versatile, high-quality bag-making machines to meet diverse and changing market needs effectively.