Are you struggling with inconsistent film strength? The problem might be your blow-up ratio1. We have the solution to optimize your film's mechanical properties for superior performance.

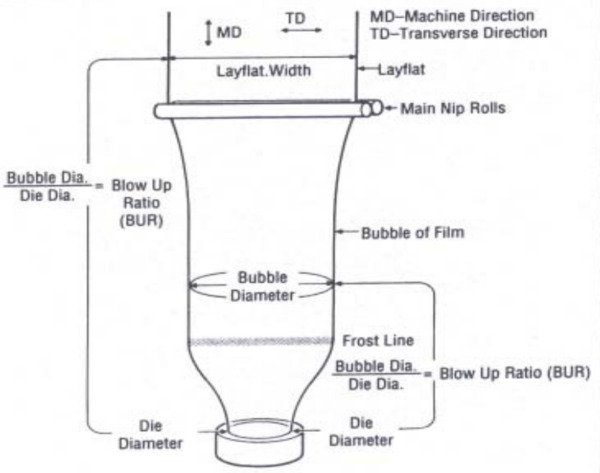

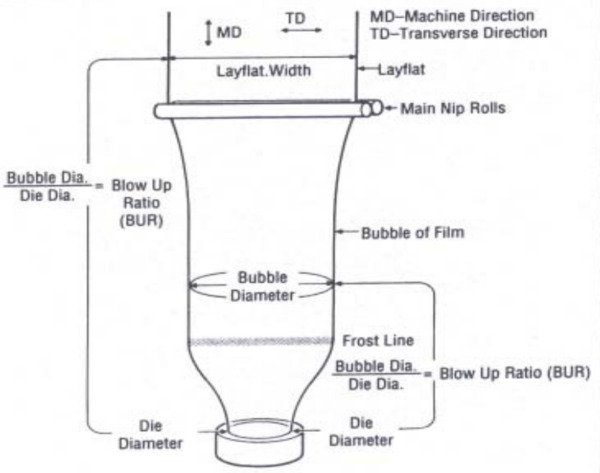

Yes, the blow-up ratio (BUR) is a critical factor. It directly influences the film's molecular orientation. A higher BUR generally increases transverse direction (TD)2 strength and tear resistance, but it can reduce machine direction (MD)3 strength and elongation.

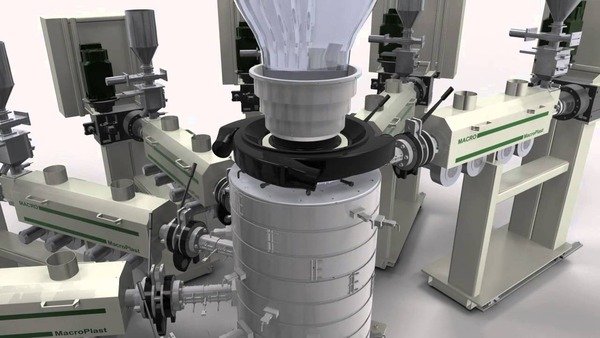

At BagMec®, we see this balance firsthand. The BUR determines how much the plastic bubble is stretched sideways compared to its upward pull. This stretching process aligns the polymer chains. When you adjust the BUR, you are deciding the film's final strength profile. A well-controlled BUR is key for making bags that meet specific needs, from heavy-duty sacks to thin retail bags. Our machines are designed to manage this process with high precision.

For instance, a low BUR results in stronger alignment in the machine direction (MD). This is good for applications needing high tensile strength along the film's length. On the other hand, a high BUR stretches the film more in the transverse direction (TD). This enhances TD tear resistance and impact strength. This is vital for bags that carry heavy or sharp contents. Finding the right ratio is a trade-off between MD and TD properties.

How do you calculate the blow-up ratio (BUR)?

Calculating the blow-up ratio is simpler than you might think. It is a basic but essential formula for any film extrusion process.

You calculate the blow-up ratio by dividing the final bubble diameter by the die diameter. The formula is: BUR = (Bubble Diameter) / (Die Diameter). This simple ratio is a key control parameter in blown film extrusion.

Why Accurate Measurement Matters

A small miscalculation can lead to large changes in film properties. Let's say you aim for a 2.5:1 BUR. But if you miscalculate and get 3.0:1, the TD strength might increase. However, the MD strength and film stability could suffer. This can cause problems in bag conversion processes. For example, it can affect sealing or printing on a machine. Our machines, such as the Lamination Pouch Making Machine, rely on consistent film properties for optimal performance.

Practical Example of Calculation

Here is a straightforward example. Imagine we use a die with a diameter of 200 mm. We inflate the bubble to a final flat width of 942 mm.

-

Find the Bubble Diameter: First, we need to find the diameter of the inflated bubble from its flat width.

- Formula: Bubble Diameter = (Flat Width x 2) / π

- Calculation: (942 mm x 2) / 3.14159 ≈ 600 mm

-

Calculate the BUR: Next, we use the BUR formula.

- Formula: BUR = Bubble Diameter / Die Diameter

- Calculation: 600 mm / 200 mm = 3.0

The result is a blow-up ratio of 3.0:1. This simple math is fundamental to controlling your film quality.

Common BUR Ranges for Different Materials

Different materials perform best within specific BUR ranges. Choosing the right one is key to getting the desired outcome.

| Film Material | Typical BUR Range | Primary Application Characteristics |

|---|---|---|

| LDPE | 2.0:1 to 4.0:1 | General purpose bags, good balance of properties. |

| LLDPE | 2.5:1 to 3.5:1 | High puncture and tear resistance for stretch films. |

| HDPE | 3.0:1 to 5.0:1 | High stiffness and tensile strength for T-shirt bags. |

| Biodegradable (PLA) | 2.0:1 to 3.0:1 | Requires careful control to avoid brittleness. |

What is the optimal BUR for different types of bags?

The "best" blow-up ratio is not one-size-fits-all. It depends completely on the bag's final use and the material you're working with.

For T-shirt bags made from HDPE, a high BUR (3:1 to 5:1) is optimal for stiffness. For heavy-duty industrial bags using LLDPE, a moderate BUR (2.5:1 to 3.5:1) provides a good balance of tear and puncture resistance.

T-Shirt Bags (HDPE)

These bags need to be thin and light. But they also need to be strong and stiff. A high BUR, like 4:1, orients the molecules sideways (TD). This provides the strength needed to prevent the bag from stretching and tearing when a customer carries groceries. At BagMec®, our T-Shirt Bag Making Machines, with prices from $17,000 to $32,000, are calibrated to handle films produced with these specific high-BUR parameters for top performance.

Heavy-Duty Sacks (LDPE/LLDPE)

Think of bags for soil, sand, or industrial resins. These require excellent puncture and impact strength. A lower BUR, such as 2.5:1, creates a more balanced orientation between MD and TD. This balance prevents the bag from failing if it is dropped or hit by a sharp object. Our heavy-duty bag machines are built to seal these thicker, more robust films effectively, ensuring the final product is reliable.

Courier & E-commerce Bags

These bags need high tear resistance in the transverse direction. This is important to prevent ripping during shipping and handling. A medium to high BUR of around 3:1 is ideal. It provides that necessary TD strength. It also maintains enough MD strength for high-speed processing on our courier bag machines. These machines often include features like adhesive strips and tear-off perforations.

How does BUR interact with other processing parameters?

The blow-up ratio does not work alone. It interacts closely with other extrusion variables. Together, they create a complex but controllable system for producing quality film.

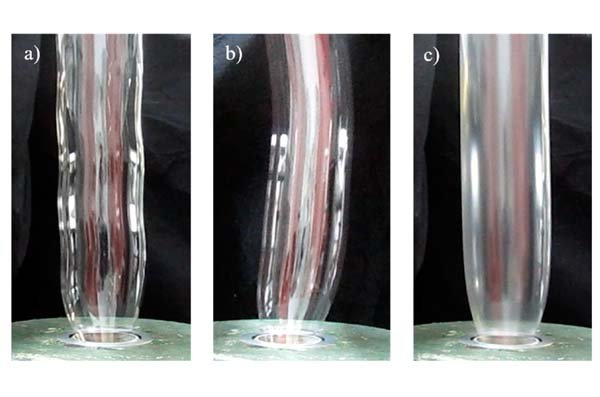

BUR works with the Frost Line Height (FLH) and Take-Up Ratio (TUR). A high BUR often requires a higher FLH to allow polymers to crystallize properly. This combination directly impacts film clarity, haze, and overall mechanical strength.

The BUR and Frost Line Height (FLH) Relationship

The frost line is the point where the molten plastic becomes a solid film. A high FLH gives the polymer chains more time to arrange themselves before they "freeze" in place. When you use a high BUR, you stretch the bubble a lot. A higher frost line helps this process happen smoothly. This results in better film clarity and more uniform properties. A low FLH with a high BUR can "shock" the material. This often leads to cloudy film and weak spots.

The BUR and Take-Up Ratio (TUR) Balance

The take-up ratio is how fast the rollers pull the film away from the die. This parameter primarily influences the machine direction (MD) properties and the film's final thickness. The interaction between TUR and BUR defines the film's profile.

- High TUR + Low BUR: This combination creates a film that is very strong in the machine direction but weak in the transverse direction. The film will be thin and easy to tear sideways.

- Low TUR + High BUR: This combination creates a film with strong TD properties. But it will likely have lower MD strength and will be thicker.

At BagMec®, our machines are engineered to work with films that have very specific property balances. For example, our "Smart Tension Control" technology helps manage film from different production setups. This ensures consistent performance from roll to finished bag, whether on a Wicketer Bread Bag Machine or a Zipper Bag Making Machine.

Conclusion

In summary, mastering the blow-up ratio is essential for controlling your film's mechanical properties. By balancing BUR with other factors like FLH and TUR, you can produce high-quality, fit-for-purpose bags. We are here to help you achieve that.

-

Understanding the blow-up ratio is crucial for optimizing film strength and performance in various applications. Explore this link for detailed insights. ↩

-

Transverse direction (TD) is essential for tear resistance and impact strength in films. Discover its importance in film manufacturing processes. ↩

-

Machine direction (MD) plays a vital role in determining the strength and durability of films. Learn more about its impact on film production. ↩