Struggling with uneven film? This can waste material and lead to inconsistent bag quality. Correctly calculating the blow-up ratio (BUR)1 is crucial for consistent quality in your film production process.

You correctly calculate the blow-up ratio (BUR) by dividing the final diameter of the inflated film bubble by the diameter of your machine's die. This simple ratio is fundamental for controlling film characteristics.

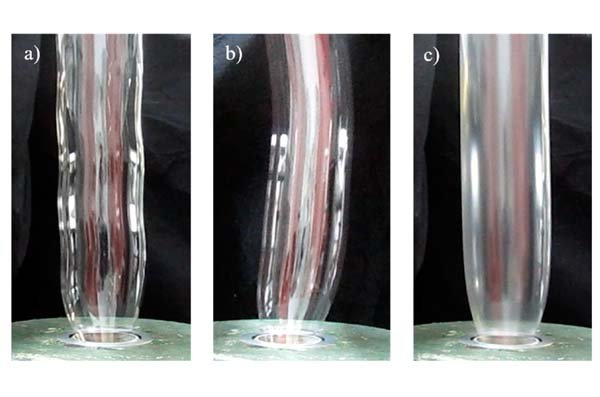

The "final diameter of the inflated film bubble" means the diameter of the bubble after it has been blown up and stabilized. This is before it is collapsed into lay-flat tubing. You need to measure this accurately. The "die diameter" is a fixed specification of your film blowing machine. This ratio is not just a number; it directly impacts how the polymer molecules align. This alignment affects the film's strength, clarity, and even its barrier properties. We always emphasize precise measurements for optimal results at BagMec®.

Precision in measuring both diameters is essential. For the bubble diameter, some operators use optical sensors. Others might use a simple, well-calibrated measuring tape carefully held against the stable bubble. The die diameter is usually found in your machine's manual from us. Small errors in either measurement can lead to a significantly different BUR. This, in turn, can mean your film is too weak in one direction or too thick. This causes problems in later bag-making processes or for the end-user. We ensure our BagMec® machine specifications are exact for this reason.

Why is knowing the correct BUR so important for bag making?

You might wonder why we focus so much on this BUR calculation. It is because the BUR greatly affects the final bags you produce with our machines.

Knowing the correct BUR is vital because it directly dictates your plastic film's mechanical properties. These include tensile strength, tear resistance, and impact strength, all crucial for bag performance and durability.

The blow-up ratio is not just a theoretical number. It has real-world results for the bags coming off your BagMec® machine. A well-controlled BUR ensures the film behaves as expected.

How BUR Influences Film Properties

The orientation of polymer chains is significantly affected by the BUR.

- Low BUR (e.g., 1.5:1 to 2.5:1): This usually results in higher machine direction (MD) orientation. This means the film is stronger and stiffer along the length of the extrusion. But, it might tear more easily in the transverse direction (TD).

- High BUR (e.g., 3:1 to 5:1): This leads to more balanced orientation or even higher TD orientation. This generally gives better overall toughness and tear resistance across both directions.

Think about the type of bag you are making.

Impact on Bag Types

Different bags need different film properties2. BUR helps control these properties.

- Heavy-Duty Bags: For products like soil or industrial parts, you need high tear and puncture resistance. A moderate to high BUR can help achieve this. It creates a tougher, more resilient film. Our heavy-duty bag machines, with prices like the Heavy duty bag machine Price: $12,000.00-23,000.00, are designed to handle films produced with optimized BUR.

- T-Shirt Bags: These bags need a good balance of strength and thinness. The BUR affects how thin you can make the film while keeping enough strength. This is especially true around the handle area. Consider our T-Shirt Bag Making Machine Price:$ 17,000-$ 32,000 for such applications.

- Food Packaging: Clarity and barrier properties can also be influenced by BUR. A more uniform molecular orientation can improve these aspects. For our food package bag machines, consistency from the film is key.

Here’s a simple look at how BUR can generally influence film properties:

| Property | Low BUR Effect | High BUR Effect | Importance for Bags |

|---|---|---|---|

| MD Tensile Strength | Higher | Lower | Bag lifting strength (handles) |

| TD Tensile Strength | Lower | Higher | Resistance to side tearing |

| Impact Strength | Moderate | Generally Higher | Resistance to dropping, punctures |

| Clarity | Can be good | Can also be good | Product visibility (e.g., bread bags) |

| Film Thickness | Easier to control thicker | Better for thinner gauges | Material cost, specific applications |

At BagMec®, we design our machines knowing that the film input, shaped by factors like BUR, is critical. Incorrect BUR does not just mean bad film. It means bad bags, possible line stoppages, and wasted resources.

What factors can impact the blow-up ratio during production?

Calculating the BUR is one thing. Keeping your target BUR steady is another challenge. Several factors can change it during real-time production.

Factors impacting BUR include air pressure inside the bubble, extruder output rate, nip roll speed, and the surrounding room temperature. The material's melt strength3 also plays a big role in keeping a stable bubble for the desired BUR.

Achieving and holding your desired blow-up ratio needs careful control over several machine settings and conditions. It is a process that is always changing. Even with our precision BagMec® machinery, operators need to know about these influences.

Key Operational Factors

Let's break down the main elements that can cause your BUR to change:

- Internal Air Pressure: This is the most direct control. More air inflates the bubble more. This increases the BUR. Too little air and the bubble might be too small or unstable. Our machines often feature precise airflow regulation systems.

- Extruder Output Rate: This is the amount of melted polymer being fed from the extruder. If the output increases without a matching adjustment in nip roll speed or air, the bubble might get thicker. It could also get smaller in diameter if not enough air is present to expand the extra material.

- Nip Roll Speed: This is the speed at which the collapsed film tube is pulled away by the nip rolls. Faster nip speeds tend to stretch the film more in the machine direction. This can also pull down the bubble diameter if other factors are not balanced. This could lead to a lower BUR or film instability.

- Melt Temperature: The temperature of the melted polymer affects its stickiness (melt strength). A hotter melt is usually less sticky and might be harder to control. This could lead to an unstable bubble that droops or changes size. Colder melts are stiffer but can cause other issues.

Material Characteristics

The polymer itself is a very big factor.

- Melt Strength: Different resins (like LDPE, HDPE, LLDPE) have different natural melt strengths. Materials with higher melt strength can support a larger, more stable bubble at a given BUR. Additives can also change melt strength. When we discuss a machine like our Lamination Pouch Making Machine (Price:$34,000.00-67,000.00), the film's stability from various layers made with specific BURs is very important.

- Material Consistency: Changes in the raw material, like inconsistent MFI (Melt Flow Index) or levels of recycled content, can cause the bubble stability and BUR to change.

Environmental Conditions

Even the area around the machine can play a part.

- Room Temperature & Air Drafts: Big temperature changes in your factory or strong air drafts can unevenly cool the bubble. This can lead to instability, uneven thickness, or make it hard to keep a steady BUR. Our Wenzhou facility, where we build BagMec® machines, is ISO 9001 certified. This ensures quality control in our own environment.

Here’s how these factors often work together:

| Factor | If it Increases... | Potential Impact on BUR (all else constant) | Machine Adjustment often Needed |

|---|---|---|---|

| Internal Air | More air supplied | Increases | Monitor bubble stability |

| Extruder Output | More material | Can Decrease (if film gets thicker) | Adjust air, nip speed |

| Nip Roll Speed | Faster pull | Can Decrease (due to drawdown) | Adjust air, extruder output |

| Melt Temperature | Hotter melt | Can become unstable, harder to maintain | Cooler air ring, reduce temp |

| Air Drafts | More inconsistent cooling | Fluctuates, hard to control | Shield bubble, control environment |

Understanding how these things interact is key for your operators. It helps them effectively manage film production. This ensures the film fed into your bag making machines, like a Zipper Bag Making Machine (Price:$15,000.00-22,000.00), is always to specification. Our "Smart Tension Control" technology, a BagMec® patented feature, helps manage some film issues. But good film starts at the blowing stage.

Conclusion

Correctly calculating and controlling your blow-up ratio is fundamental. It ensures consistent film quality, optimal bag performance, and efficient production. We at BagMec® are here to help you master this process.

-

Understanding BUR is essential for optimizing film quality and ensuring consistent bag performance in production processes. ↩

-

Exploring film properties can help you understand how to enhance bag durability and performance, crucial for various applications. ↩

-

Learning about melt strength can provide insights into material selection and processing for better film stability and quality. ↩