Are you struggling with inconsistent film quality from your film blowing machines? This often leads to material waste and weak bags. We use real-time, automated monitoring to maintain a perfect blow-up ratio1 (BUR) and ensure consistently superior output.

We monitor blow-up ratio changes using integrated PLC systems connected to ultrasonic or laser sensors. These sensors continuously measure the film bubble diameter, while the system automatically adjusts air volume and take-up speed to maintain the preset ratio with precision.

This process is not a simple manual check; it's a dynamic, closed-loop feedback system built into our machines. The Programmable Logic Controller (PLC)2 acts as the brain. It constantly compares the real-time data from the sensors against the parameters you set on the touchscreen interface. If any deviation occurs, even a minor one, the system makes an immediate and calculated adjustment. This proactive control is crucial for handling different materials, from standard LDPE/HDPE to sensitive biodegradable PLA films, ensuring uniformity from the first bag to the last.

Our goal is to eliminate the variables that cause production headaches. The system's automated nature means it can instantly correct for subtle changes that a human operator might miss. For instance, a slight drop in ambient temperature or a minor change in material melt flow could alter the bubble size. Our system catches these shifts in milliseconds, preventing small inconsistencies from escalating into a batch of defective products. This is a core component of our fully automated production lines, designed for maximum efficiency and minimal waste.

What factors cause the blow-up ratio to change?

To maintain a stable process, it's important to understand what can disrupt it. Several factors can cause your blow-up ratio to fluctuate during production.

The main factors that cause blow-up ratio changes are fluctuations in material melt flow, inconsistent die head temperature, variations in ambient factory conditions, and changes in extruder output speed. Each of these can directly impact the stability and size of the film bubble.

Let's dive deeper into these common causes and how our machine design helps mitigate them.

Material Inconsistency

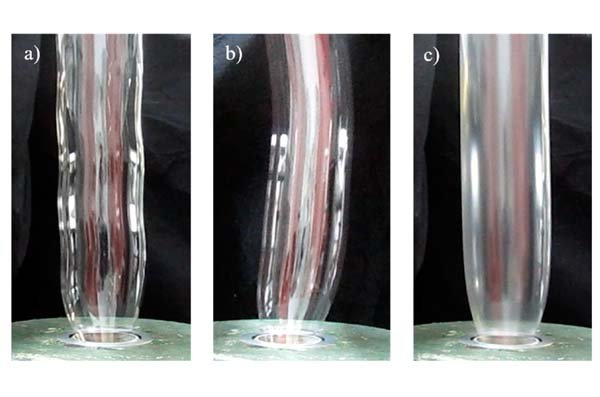

The Melt Flow Index (MFI) of your polymer resin is critical. If you use materials with an inconsistent MFI, or blend virgin resin with recycled content, the flow out of the die can vary. This causes the bubble to become unstable.

Thermal and Environmental Changes

The temperature of the die head must be perfectly uniform. A cool spot can cause the film to be thicker on one side. Also, external factors like a draft from an open door or changes in your factory's air temperature can cause the bubble to cool at a different rate, making it shrink or expand unexpectedly.

Machine-Related Variables

The performance of the machine itself is key. For example, if the extruder screw speed is not perfectly steady, the amount of molten plastic being pushed out will change. Likewise, inconsistent speed at the nip rollers, which pull the film upward, can stretch the bubble unevenly.

Here is a simple breakdown of these factors and our technical solutions:

| Factor | Common Impact on Film Bubble | BagMec® Machine Solution |

|---|---|---|

| Material Melt Flow | Unstable bubble, variations in thickness | Precision screw and barrel design for consistent melting |

| Die Head Temperature | Hot or cold spots create gauge bands | Multi-zone PID temperature controllers for ±1°C accuracy |

| Ambient Air | Drafts can cause the bubble to collapse or shrink | An optional enclosed bubble cage to shield from external air |

| Extruder/Nip Speed | Inconsistent pulling stretches film unevenly | High-precision servo motors and our "Smart Tension Control3" system |

What technology do we use to ensure a stable blow-up ratio?

Simply knowing the causes isn't enough. You need the right tools for the job. We don't leave stability to chance; we engineer it directly into our systems.

To ensure stability, we integrate advanced technology like PLC automation, non-contact ultrasonic sensors, and our patented "Smart Tension Control." This combination creates a closed-loop system that automatically maintains the target blow-up ratio without manual intervention.

Our approach is built on a foundation of reliable, interconnected technologies that work together to deliver consistent results.

PLC-Based Automation

The heart of our system is a robust Programmable Logic Controller (PLC). This is the central computer that manages the entire process. Operators can easily input all production parameters, including the desired BUR, film thickness, and line speed, using a user-friendly touchscreen interface available in multiple languages. The PLC then takes over, executing these commands with digital precision.

High-Precision Sensors

Our machines use non-contact ultrasonic or laser sensors mounted around the film bubble. These sensors emit signals and measure the time it takes for them to bounce back, calculating the bubble's diameter with sub-millimeter accuracy. Because they are non-contact, they don't risk marking or tearing the delicate film. This constant stream of data is fed directly back to the PLC.

"Smart Tension Control" System

This is one of our key patented technologies. Maintaining a stable bubble is only half the battle; how you pull the film away is just as important. Our "Smart Tension Control" system uses servo-driven nip rollers that adjust their speed in real time. This ensures the film is drawn away from the die with perfectly consistent tension, preventing stretching that could distort the bubble's dimensions and the film's orientation. This technology was crucial for a German client, helping them reduce material waste by 18%.

How does an unstable blow-up ratio affect bag quality?

An unstable blow-up ratio is more than just a technical issue. It has a real and immediate impact on the quality of your finished bags and your bottom line.

An unstable ratio directly leads to inconsistent film thickness. This causes weak spots that tear easily, poor heat sealing, uneven printing, and ultimately, a higher rate of product failure. It undermines the reliability and appearance of every bag you produce.

The consequences of poor BUR control can affect your entire operation, from production costs to customer satisfaction.

| Problem from Unstable BUR | Consequence for the Bag | Impact on Your Business |

|---|---|---|

| Thin Spots (Low Gauge) | Bag tears easily, especially at seams. | Increased customer complaints and returns. Product loss. |

| Thick Spots (High Gauge) | Inconsistent texture, potential sealing issues. | Wasted raw material, increased production costs per bag. |

| Gauge Bands (Streaks) | Uneven surface for printing, poor visual appeal. | Damaged brand perception. Unprofessional appearance. |

| Poor Sealing | Seams may not bond correctly due to thickness variance. | Compromised package integrity, especially for food or liquids. |

For a client like Priya Kapoor in India, whose e-commerce startup relies on durable courier bags, a batch of bags with weak seals could be catastrophic. Our machines provide the consistency she needs to protect her shipments and her brand.

Can you walk through a real-life adjustment scenario?

Let's put this all together with a practical example. Imagine Hans Fischer, a procurement manager from Germany, running one of our machines for food packaging.

In a real-life scenario, a sensor detects a 0.5% decrease in bubble diameter due to a drop in ambient temperature. The PLC instantly calculates the required adjustment and slightly increases airflow to the die, restoring the target BUR within two seconds, with no production interruption.

Here is a step-by-step breakdown of how our automated system responds.

Step 1: A Disturbance Occurs

The facility's air conditioning system cycles on, blowing a current of cool air near the production line. This causes the outer surface of the film bubble to cool faster than normal, and it begins to shrink slightly. The change is too small for an operator to see with the naked eye.

Step 2: Instantaneous Detection

Our ultrasonic sensor, which measures the bubble diameter 20 times per second, immediately detects the slight reduction. It sends a new data point to the PLC, flagging a deviation from the target BUR that Hans programmed.

Step 3: Automated Correction

The PLC's algorithm instantly processes this information. It determines that a minor, controlled increase in air volume from the internal blower is needed to counteract the shrinkage. It sends a precise signal to the air valve, which opens micro-metrically to increase pressure.

Step 4: System Stabilization and Reporting

The bubble expands back to its exact target diameter. The sensor confirms the stable reading, and the system returns to a monitoring state. The entire event, from detection to correction, takes less than three seconds. This event is logged in the machine's production data, which can later be analyzed for process optimization.

Conclusion

Monitoring blow-up ratio is not about occasional checks; it is about continuous, automated control. Our machines provide this real-time precision, ensuring consistent bag quality, minimizing material waste, and maximizing the reliability of your entire production line. This is the BagMec® commitment.

-

Understanding the blow-up ratio is crucial for maintaining film quality and reducing waste in production. Explore this link for in-depth insights. ↩

-

Learn how PLCs enhance automation and efficiency in manufacturing processes, ensuring consistent quality and performance. ↩

-

Discover how Smart Tension Control technology optimizes film production, ensuring uniformity and reducing material waste. ↩