Piping bag making machines typically cost between $7,500 and $9,500, depending on features and configuration. For instance, the BagMec® 500 model starts at around $8,000, offering automatic correction, optical tracking, and production speeds of 100–200 bags per minute.

This price reflects more than just the hardware. It includes advanced automation, durable construction, and operational efficiency. Features like photoelectric tracking1 reduce waste by ensuring precise printing alignment, while computer controls simplify operation.

When comparing machines, it’s important to understand what the price includes. For example, machines with servo motors2 cost more but deliver greater precision and speed than those with stepper motors—resulting in better long-term value.

What Is a Piping Bag Making Machine Used For?

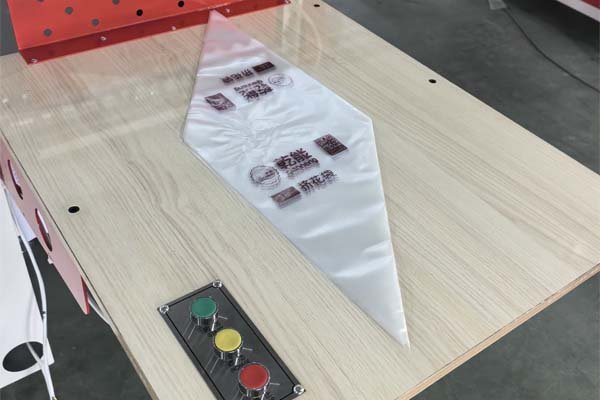

Piping bag making machines are designed to heat-seal PE film3 into triangular or specialty bag shapes. They are commonly used in the food industry to produce disposable piping bags for cake decorating, candy filling, and more.

The machine automates this process from film feeding to cutting, ensuring uniform results and efficient production.

Core Functions

- Feeding: Film is pulled from a roll and aligned using auto-correction systems.

- Sealing: Heated bars apply precise pressure at a 45° angle to create strong seams.

- Cutting: The sealed film is cut into individual bags.

- Counting: The system counts each finished bag and can trigger alarms when batch goals are met.

Common Applications

| Industry | Primary Use | Bag Type |

|---|---|---|

| Bakery & Pastry | Icing and decorating | Triangular cream bags |

| Confectionery | Dispensing melted chocolate or syrup | Small candy filling bags |

| Food Service | Applying sauces or purees | Disposable kitchen piping bags |

| Crafts & Hobbies | Precision liquid dispensing | Small applicator bags for glue/paint |

What Factors Affect Piping Bag Machine Prices?

![]()

Several variables impact machine pricing:

- Motor type (servo vs. stepper)

- Automation level

- Component quality

- Machine size

- Brand and manufacturer reputation

Drive Systems

- Stepper Motor: Cost-effective, reliable for basic production. Standard in most entry-level machines.

- Servo Motor: Higher cost, smoother motion, better accuracy, suitable for high-volume operations.

Automation and Controls

- Microcomputer Control: Enables precise settings for bag size and performance.

- Photoelectric Tracking: Ensures print alignment and halts production if the mark is lost.

- Auto Counting & Alarms: Allows unattended operation with real-time batch feedback.

Key Components

| Component | Brand/Origin | Role in Performance |

|---|---|---|

| Motor | Jiangsu | Provides consistent, durable power |

| Inverter | Shanghai | Regulates motor speed, saves energy |

| PLC (Computer Control) | Shanghai | Core control system, reduces errors |

| Auto Correction System | Ningbo | Maintains film alignment |

| Magnetic Powder Tension | Ningbo | Ensures steady film tension |

Industrial vs. Small-Scale Piping Bag Machines

The main difference lies in production speed and durability.

Industrial machines like the BagMec® 500 operate continuously at high speeds (up to 200 bags/min), while small desktop models are slower and built for light-duty use.

Comparison Table

| Feature | Small/Desktop Machine | Industrial Machine (BagMec® 500) |

|---|---|---|

| Production Speed | 30–80 pcs/min | 100–200 pcs/min |

| Duty Cycle | Occasional use | 24/7 continuous use |

| Frame & Components | Lightweight | Heavy-duty, 900kg |

| Automation | Minimal | Full automation with tracking |

| Space Requirements | Compact | Large (4100×1200×1300mm) |

| Film Waste | Higher risk | Reduced via auto-correction |

| Price Range | Lower | ~$8,000+ |

| Ideal Use Case | Small business, hobbyist | Mid to large-scale manufacturers |

Features of the BagMec® 500 Model

The BagMec® 500 is designed for industrial performance with:

- Microcomputer controls

- High-speed output (100–200 bags/min)

- Photoelectric tracking

- Automatic deviation correction

- Constant temperature sealing

- Automatic counting and alarms

Technical Specs

| Specification | Value |

|---|---|

| Model | 500 Type |

| Max. Bag Length | 420mm |

| Speed | 100–200 pcs/min |

| Sealing Angle | 45° |

| Power | 220V (customizable) |

| Machine Weight | 900kg |

| Dimensions | 4100mm × 1200mm × 1300mm |

How to Choose the Right Machine for Your Factory

Making the right investment involves careful planning:

- Define Your Output Needs: Match machine speed to your order volume and bag sizes.

- Check Film Compatibility: Ensure your material works with the machine (standard is PE film).

- Set Budget and ROI Goals: Consider initial cost versus long-term savings from speed and waste reduction.

- Assess Support and Warranty: Choose a supplier that provides installation, training, and post-sale support.

Where to Buy a Reliable Piping Bag Machine in China

To ensure product quality and reliability, consider manufacturers with:

- Proven experience

- Certifications (ISO 9001, CE)

- Real customer success stories

- Direct communication and virtual tours

What to Look For

- Company History: BagMec® has operated since 2017 with in-house R&D.

- Certifications:

- ISO 9001: Verifies quality management

- CE: Confirms compliance with EU safety standards

- Case Studies:

- German packaging firm improved efficiency

- Indian logistics provider received custom solutions

- U.S. eco-brand co-developed compostable bag technology

Reach out to manufacturers directly to assess responsiveness and professionalism.

Is Customization Available?

Yes, customization is possible based on business needs.

Common Customizations

- Servo Motor Upgrade: Improves speed and accuracy

- Voltage/Plug Configuration: Adapts machine to local standards

- Multi-language Interface: Available in English, Chinese, Spanish, and more

- Add-ons: Options for printing, embossing, or special bag shapes

How to Request Customization

- Initial Contact: Share your needs with the supplier

- Free Engineering Consultation

- Proposal Review: Receive specs, timeline, and pricing

Conclusion

Piping bag machine pricing generally starts around $8,000 for industrial models. The right choice depends on your production goals, budget, and the level of automation you require. Understanding your needs and working with an experienced supplier will ensure a machine that delivers long-term value and performance.