Controlling each layer in co-extrusion is a big challenge. Poor control means weak film and wasted material. But we have precise methods to manage this process perfectly.

You don't control the blow-up ratio (BUR) for individual layers separately. Instead, you control the overall BUR of the entire film bubble. We then precisely manage each layer's thickness by adjusting the output of each individual extruder.

This idea is central to multi-layer film production. The blow-up ratio is a property of the whole structure. It is the ratio between the final bubble diameter and the die orifice diameter. We manage this overall size with systems like the air ring and internal bubble cooling (IBC). The real control for each layer comes from the material feed. We focus on the screw speed and melt flow of each extruder. By changing how much polymer goes into each layer, we dictate its thickness and performance characteristics within the final film.

So, the process involves two main actions. First, we set the total bubble size to get the desired film width and general properties. This is a macro-level adjustment. Second, we fine-tune the output of each of the multiple extruders. This is the micro-level adjustment. For a 5-layer film, we are managing five separate extruders to create the perfect recipe. This combination of overall and individual control gives us the power to produce complex, high-performance films for any application.

What role does the die design play in layer control?

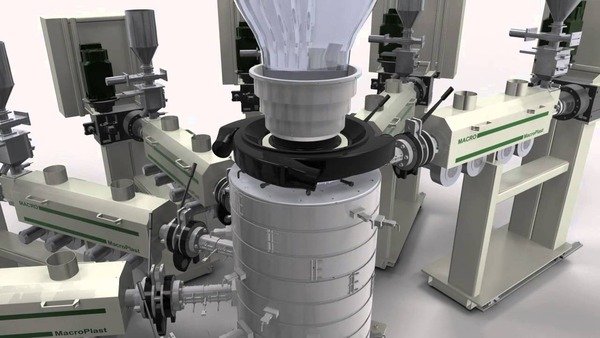

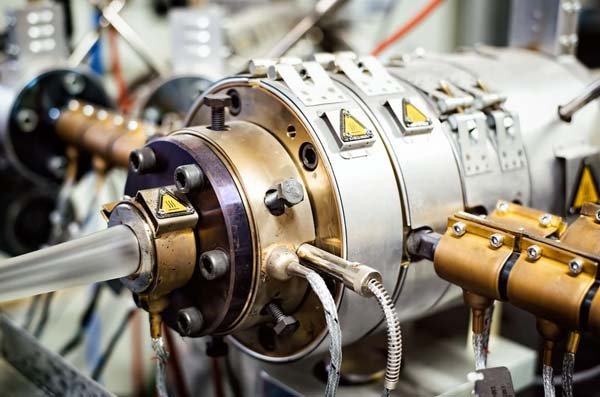

The die is not just a piece of metal. It is the heart of the machine. Its design is critical for creating a high-quality, multi-layer film.

A well-designed die has separate internal channels that guide each polymer melt. These channels keep the layers distinct and distribute them evenly before they merge. This prevents weak spots and ensures consistent layer thickness across the film.

The internal geometry of the die is where our engineering shines. Two common designs exist, each with its own strengths.

Stack Dies vs. Spiral Mandrel Dies

A stack die consists of several flat plates stacked on top of each other. Each plate has a channel for one polymer layer. The layers combine just before exiting the die. This design is simpler and less expensive. But it can sometimes create "port lines" or small imperfections in the film where the melt streams meet.

A spiral mandrel die is more advanced. In this design, the polymer flows through spiral channels cut into a central cylinder, or mandrel. This ensures a very smooth and uniform flow for each layer. The layers are combined more gently, resulting in superior film quality with no flow lines. We at BagMec® recommend spiral mandrel dies for high-performance applications like food packaging or medical films.

How We Choose the Right Die

Our decision depends entirely on your product needs. We use flow simulation software to model how different polymers will behave inside the die. This helps us prevent common issues, like a low-viscosity material completely wrapping around a higher-viscosity one.

| Feature | Stack Die | Spiral Mandrel Die |

|---|---|---|

| Layer Uniformity | Good | Excellent |

| Number of Layers | Best for 2-3 layers | Ideal for 3-11+ layers |

| Melt Distribution | Can be uneven | Highly uniform |

| Cost | Lower | Higher |

| Best For | General purpose bags | Food, medical, barrier films |

This careful engineering ensures that each layer maintains its integrity from the extruder to the final film.

How does material choice affect layer ratio control?

Choosing the right raw materials is just as important as the machine itself. A poor material combination can cause major production problems and bad film quality.

Each plastic material has a unique melt strength and flow rate. We must match these properties for stable co-extrusion. If materials are incompatible, layers can be uneven. We manage this by adjusting temperatures and selecting compatible polymer grades.

Material compatibility is key. We cannot just mix any plastic and expect good results. Certain properties must be aligned for the process to work smoothly.

The Role of Melt Flow Index (MFI)

Melt Flow Index1, or MFI, is a number that tells us how easily a polymer flows when melted. In co-extrusion, the MFIs of adjacent layers should be similar. A large difference can cause instability. For example, if we try to extrude a very high MFI material next to a very low MFI one, the high-MFI layer may flow too quickly. This would create a layer that is too thin and weak. We help clients select polymer grades with compatible MFIs to avoid this.

The Need for Tie Layers

Some materials do not stick to each other. A common example is polyethylene (PE) and ethylene vinyl alcohol (EVOH). EVOH is an excellent oxygen barrier, perfect for food packaging. But it will peel right off PE without help.

This is where a tie layer2 comes in. A tie layer is a special adhesive polymer that we extrude as a separate, thin layer between the PE and EVOH. It acts like glue, bonding the two incompatible layers together. This ensures the final film is strong and does not delaminate.

| Material Combination | Primary Use | Control Challenge | BagMec® Solution |

|---|---|---|---|

| LDPE / LLDPE | Shopping bags | Balancing strength and stiffness | Precise extruder speed and temperature control. |

| HDPE / Tie / EVOH | Food barrier film | Adhesion and barrier consistency | Advanced spiral die and dedicated extruder for the thin tie layer. |

| PLA / PBAT | Compostable bags | Different melt stability | Custom screw designs and dehumidifying systems to handle sensitive biomaterials. |

Can automated systems3 improve layer consistency?

Manual controls are effective, but automation provides a level of precision that is impossible to achieve by hand. It brings consistency and reduces material waste.

Yes, automated systems are essential for top-tier quality. They use sensors to measure the film's thickness profile in real-time. This information is sent to a central computer, which automatically adjusts the machine to correct any variations instantly.

Modern film lines rely on smart, closed-loop control systems. These systems do not just set a speed and hope for the best. They actively measure the output and make constant micro-adjustments to maintain perfect specifications.

Gravimetric Weight Control

Instead of just controlling the speed of the extruder screw, advanced systems use gravimetric control. This technology weighs the raw material pellets as they are fed into each extruder. It ensures that the exact weight of material per hour is processed. This is far more accurate than just measuring volume, as it compensates for differences in material density. This precise control of mass flow is fundamental to maintaining the correct layer ratio.

Automatic Profile Control (APC)

An APC system uses a scanner that moves across the flat film. This scanner measures the thickness at hundreds of points. If it detects a spot that is too thick or too thin, it takes action automatically. It can send signals to a special air ring that increases or decreases cooling air in that specific area. More cooling air makes the film thinner. This system ensures the film has a uniform thickness from edge to edge, which is critical for printing and bag conversion later.

Our BagMec® Smart Tension Control system works with these automated technologies. Based on data from machines we've installed, clients have reduced material waste by up to 18% while achieving 99% uptime.

Conclusion

To master multi-layer film, we focus on the whole picture. We control the overall blow-up ratio for film width. Then, we use precise extruder control, advanced die design, and smart automation to manage each layer's thickness, creating the perfect film structure.

-

Understanding MFI is crucial for ensuring stable co-extrusion and preventing film quality issues. Explore this link for in-depth insights. ↩

-

Tie layers are essential for bonding incompatible materials in film production. Discover more about their role and benefits here. ↩

-

Automation significantly improves precision and reduces waste in film production. Learn how these systems work for better quality. ↩