Are you struggling to get consistent film quality from your blown film line? It can be frustrating when film tears, thickness varies, or clarity isn't up to par. Understanding how to properly adjust the blow-up ratio (BUR) is a game-changer for your entire production.

Adjusting the blow-up ratio directly changes key film properties like thickness, strength, and clarity. It also affects the stability of the film bubble and the overall efficiency of your production line, influencing output and waste levels.

The blow-up ratio, or BUR, is a fundamental setting in blown film extrusion. It's the ratio of the final diameter of the film bubble to the diameter of the die. When we talk about adjusting it, we're essentially controlling how much the plastic is stretched sideways as it's inflated. This stretching process orients the polymer molecules, which in turn dictates many of the film's final characteristics. Getting this ratio right is crucial not just for the film itself, but for smooth, efficient machine operation.

Think about it: a smaller change in the BUR can have a big impact. If the BUR is too high, the film might become too thin and weak, or the bubble could become unstable. If it's too low, the film might be too thick, less clear, and you might not get the desired balance of properties. We at BagMec® understand these nuances, and our machines are designed to give you precise control over this critical parameter.

How Does BUR Directly Impact Key Film Properties?

So, you're tweaking the BUR. What exactly happens to the film you're producing? Let's look closer.

Changing the BUR primarily alters film thickness, its mechanical strength in different directions (machine and transverse), and optical properties like clarity and haze. It also influences barrier characteristics and overall molecular orientation within the film material.

When we adjust the BUR, we're directly manipulating the biaxial orientation of the polymer chains. This orientation is key to many final film attributes.

Impact on Film Thickness and Uniformity

A higher BUR means the same amount of polymer melt is stretched over a larger circumference.

- Result: The film becomes thinner.

- Benefit: This is a primary way to control gauge and achieve the desired film thickness.

- Challenge: Ensuring this thinning is uniform across the bubble width is essential. Non-uniformity can lead to weak spots or areas that are too thick. Our BagMec® machines focus on even air distribution and die design to help maintain this consistency.

Modifying Mechanical Strength

The orientation of polymer molecules significantly affects strength.

- Tensile Strength: Generally, a higher BUR can increase transverse direction (TD) tensile strength because more molecules align sideways. Conversely, machine direction (MD) tensile strength might decrease slightly or change less dramatically. Finding the right balance is key for the film's application.

- Tear Strength: This is also influenced. For instance, increasing BUR might improve MD tear strength while potentially reducing TD tear strength, or vice-versa depending on the material and specific BUR range.

Here's a simplified look:

| Property | Effect of Increasing BUR (General Trend) | Why? |

|---|---|---|

| Film Thickness | Decreases | Material spread over larger area |

| TD Tensile Strength | Tends to Increase | Greater molecular orientation in TD |

| MD Tensile Strength | May Decrease or Stay Similar | Less dominant orientation in MD |

| Clarity | Tends to Improve | Better biaxial orientation, smoother surface |

Enhancing Optical Properties

Clarity and haze are crucial for many packaging applications.

- Clarity: A higher BUR often leads to improved film clarity. The increased biaxial orientation can create a more uniform structure, reducing light scattering.

- Haze: Consequently, haze levels may decrease, making the film more transparent.

This is particularly important for retail packaging where product visibility is essential.

Influence on Other Properties

Beyond the main ones, BUR can also affect:

- Barrier Properties: The way molecules are oriented can impact how well the film acts as a barrier to gases like oxygen or moisture. A more tightly packed, well-oriented structure can sometimes improve barrier performance.

- Crystallinity: The stretching and cooling rates influenced by BUR can affect the degree and type of crystallinity in the polymer, which also ties back to mechanical and barrier properties.

What Production Process Adjustments Are Needed When Changing BUR?

Adjusting the BUR isn't just a theoretical change; it has real, practical effects on how your film line runs.

When you change the BUR, you often need to adjust air flow to the bubble, cooling efficiency, nip roll speed, and potentially the die gap to maintain a stable bubble and achieve consistent film quality at the desired output rate.

The entire blown film process is a delicate balance. Changing one parameter like BUR often necessitates a series of other adjustments to keep everything running smoothly and efficiently.

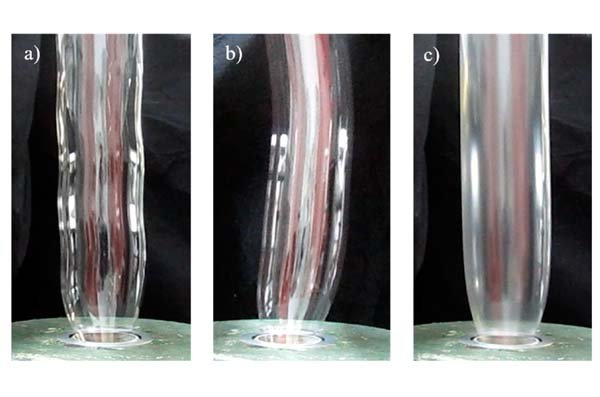

Managing Bubble Stability

This is perhaps the most immediate challenge.

- Larger Bubbles (Higher BUR): These can be more prone to instability from drafts or inconsistencies in air flow. The internal bubble cooling (IBC) system, if present, becomes even more critical. The air ring's performance is paramount.

- Smaller Bubbles (Lower BUR): While generally more stable, ensuring proper formation and adequate cooling is still important.

As a machine manufacturer, BagMec® designs air rings and control systems that aim for maximum bubble stability across a range of BURs.

Cooling System Adjustments

The size of the bubble directly impacts how it interacts with the cooling air.

- Air Flow Volume & Velocity: A larger bubble surface (from higher BUR) might require more cooling air or adjustments to how the air is directed to cool the film evenly and efficiently before it reaches the frost line.

- Frost Line Height (FLH): The BUR can influence where the frost line forms. Adjustments to cooling are often needed to maintain the FLH at the optimal position for the desired film properties. An FLH that's too high or too low can affect orientation and clarity.

Optimizing Output and Line Speed

Your BUR setting can influence how fast you can run your line.

- Cooling Limitation: Often, production speed is limited by how quickly the film can be cooled. A very high BUR might create a very thin film that cools quickly, potentially allowing for higher speeds, but only if the bubble remains stable.

- Nip Roll Speed: This must be synchronized with the extruder output and the BUR to ensure consistent film thickness and prevent issues like film sagging or excessive tension.

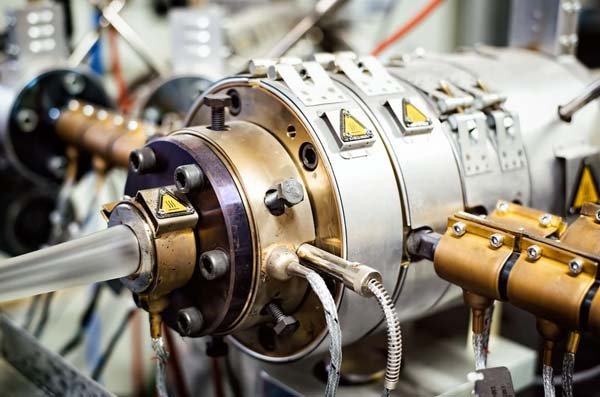

Die and Air Ring Considerations

Minor adjustments or awareness here can be important.

- Die Gap: While not always changed with every BUR adjustment, for significant shifts in film thickness ranges, die gap optimization might be considered, although BUR is the more common daily adjustment tool for thickness.

- Air Ring Precision: The design of the air ring is crucial. Dual-lip air rings, for example, offer better control and cooling efficiency, which supports a wider range of stable BUR operation. Our BagMec® machines often feature advanced air ring designs for this reason.

How Can We at BagMec® Help You Master BUR for Optimal Output?

Understanding BUR is one thing; having machinery that allows you to control it precisely and reliably is another.

At BagMec®, our machines are engineered with features for precise BUR control, stable bubble management, and consistent film quality. We provide robust equipment and the expertise to help you optimize your film production processes effectively.

We don't just sell machines; we provide solutions. Helping you get the best out of your blown film extrusion line is our priority.

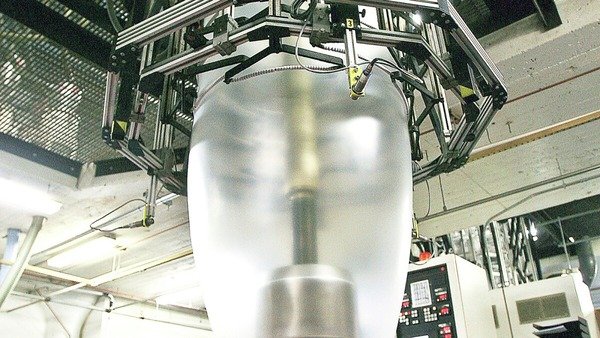

Precision Engineering in BagMec® Machines

Our blown film lines are built with the operator in mind.

- Die Design: Our dies are manufactured for uniform melt distribution, which is the foundation for a stable bubble and consistent film.

- Advanced Air Rings: We incorporate air ring designs that provide even and efficient cooling, critical for maintaining bubble stability across various BURs and for achieving better film properties.

- Control Systems: Intuitive PLC controls with touchscreen interfaces allow for precise adjustments of air flow, temperature, and line speed, giving operators the tools they need to fine-tune the BUR and other parameters.

The Role of "Smart Tension Control" and Other Innovations

While not directly adjusting BUR, related technologies on our machines contribute significantly.

- "Smart Tension Control": This patented BagMec® technology ensures consistent film feeding and winding. A stable web path after the film is made reduces issues that might otherwise be wrongly attributed to BUR problems, ensuring the properties achieved through BUR are maintained.

- Energy-Saving Servo Motors: These provide precise speed control for extruders and nip rolls, crucial for maintaining the delicate balance required when operating at specific BURs. This precision helps prevent fluctuations that could destabilize the bubble.

Training and Support for Your Team

We believe in empowering our customers.

- On-Site Installation & Training: Our technicians can provide comprehensive training on how to operate the machinery effectively, including best practices for adjusting BUR for different materials and desired film outcomes.

- Ongoing Support: If you're facing challenges in achieving specific film properties or maintaining bubble stability, our team is here to help troubleshoot and offer guidance. We want you to maximize your machine's potential. Your success is our success.

Custom Solutions for Your Specific Film Needs

Different films require different BUR strategies.

- Material Compatibility: Whether you're running LDPE, HDPE, LLDPE, or even biodegradable materials like PLA, we can help you understand how BUR interacts with each.

- Application-Specific Advice: Film for heavy-duty bags will have different BUR considerations than film for high-clarity food packaging. We can share our experience to guide you.

Conclusion

Adjusting the blow-up ratio is a powerful tool in blown film production. It impacts film properties and process stability. With the right knowledge and precise machinery from BagMec®, you can master BUR for optimal quality and efficiency.