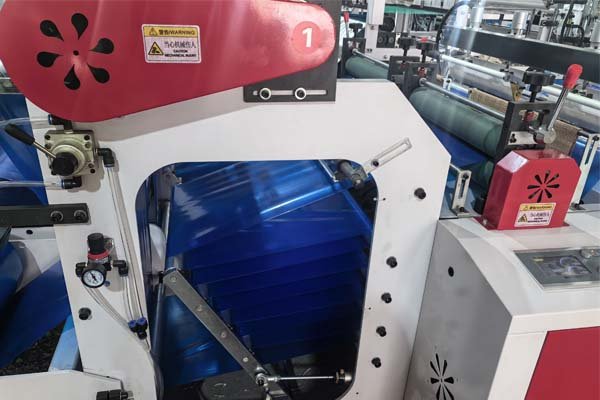

A non-stretch flat bag making machine1 is designed to convert non-stretchable plastic films into finished flat bags. It seals and cuts the material using heat without stretching or deforming it, producing clean, consistent side seals.

These machines are typically used to manufacture basic, functional bags. A roll of film is fed through the machine, side seals are applied, and individual bags are cut. “Non-stretch” refers to the materials used—such as HDPE or thick LDPE—which retain their shape and thickness throughout the process. The machine is optimized to preserve these properties.

The machine operates by first unwinding a film roll under controlled tension. Then, a heated sealing bar creates the side seams. Finally, a cutting blade slices the film to form individual bags. This straightforward design makes the machine efficient and reliable for large-scale production of durable bags.

What Materials Are Used in Non-Stretch Flat Bags?

Non-stretch flat bag making machines are best suited for films that do not elongate during processing. Common materials include:

HDPE, LDPE, PP, and biodegradable options like PLA—each selected for its compatibility with the machine’s sealing and cutting process.

These films work well because they maintain their shape during sealing, simplifying the mechanical design and increasing reliability.

High-Density Polyethylene (HDPE)

HDPE is stiff and opaque, offering high strength and puncture resistance.

- Common Uses: Trash bags, industrial liners, parts bags.

- Why It Works: Its rigidity prevents deformation, making it ideal for thick-gauge films (up to 0.3mm).

Low-Density Polyethylene (LDPE)

LDPE is more flexible and clearer than HDPE, though still non-stretch in this context.

- Common Uses: Utility bags, food storage, hardware packaging.

- Why It Works: Seals at lower temperatures and tolerates process variability well.

Polypropylene (PP)

PP is known for its stiffness and clarity, making it suitable for visually appealing packaging.

- Common Uses: Apparel packaging, greeting cards, snack food bags.

- Why It Works: Maintains a clean, glossy look after sealing and cutting.

Material Comparison Table

| Material | Key Property | Common Bag Type | Why It's a Good Fit with These Machines |

|---|---|---|---|

| HDPE | Stiff & Strong | Trash Bags, Liners | Retains shape and thickness during sealing. |

| LDPE | Flexible & Versatile | Food & Utility Bags | Easy sealing over a range of thicknesses. |

| PP | High Clarity & Stiff | Retail & Display Packaging | Creates clean, visually appealing bags. |

| PLA | Biodegradable & Rigid | Eco-Friendly Retail Bags | Rigid enough for consistent sealing; supports sustainability. |

How Much Does a Non-Stretch Flat Bag Making Machine Cost?

Prices for non-stretch flat bag making machines typically start at $10,000 USD. Depending on features and configurations, they can cost up to $18,500 or more.

Cost varies based on:

1. Machine Configuration and Capacity

- Single-lane machines are more affordable.

- Dual-lane models offer higher output and increase cost.

- Bag size capabilities also influence pricing.

2. Automation Level

- Basic models require manual input and oversight.

- Advanced models offer features like PLC touchscreens, servo motors, and pneumatic film loading, increasing automation and efficiency.

3. Component Quality

- Entry-level machines use a robust iron-plate frame.

- Premium models may feature high-end components like servo systems and upgraded tension control.

Sample Price Breakdown

| Tier | Description | Price Range (USD) | Best For |

|---|---|---|---|

| Entry-Level | Single-lane, standard build | $10,000 – $13,000 | Small operations |

| Mid-Range | Single/Dual-lane, partial automation | $13,000 – $16,000 | Mid-size businesses |

| High-End | Dual-lane, fully automated, precision components | $16,000 – $18,500+ | High-volume production lines |

How to Choose the Best Non-Stretch Flat Bag Making Machine

Selecting the right machine involves aligning its capabilities with production requirements.

Step 1: Define Product Requirements

- Bag Size: Identify minimum and maximum width and length. Machines can handle up to 500mm width and 1500mm length.

- Material Type and Thickness: Consider the film's composition and thickness (0.001mm–0.3mm). Choose a machine suitable for that range.

Step 2: Evaluate Production Needs

- Output Volume: Estimate daily or shift-based production.

- Automation Needs: Machines with features like PLC touchscreens and auto-tension control are easier to operate with fewer errors.

Step 3: Assess Build Quality

- Frame: A full-iron-plate body provides stability and durability.

- Core Components: Check quality of bearings (e.g., Harbin), sealing bars, and cutting blades.

What Makes These Machines Efficient and Durable?

Efficiency and durability depend on key design choices.

Efficiency Features

1. Precision Servo Motor

- Controls film feeding with accuracy, reducing waste and ensuring consistent bag sizes.

2. Automatic Tension Control

- Maintains film tension during unwinding, preventing wrinkles and misfeeds.

3. Dual-Lane Production

- Allows simultaneous bag production, doubling output without increasing footprint.

Durability Features

1. Rigid Frame Construction

- An iron-plate frame reduces vibrations and ensures long-term structural integrity.

2. High-Quality Bearings

- Bearings like Harbin ensure smooth rotation and reduce wear.

3. Robust Sealing and Cutting System

- Uses heating tubes and high-temp fabric on sealing bars for even heating.

- Simple, durable design extends lifespan.

How to Choose a Reliable Manufacturer

Manufacturer selection impacts both machine quality and ongoing support.

Step 1: Review Experience and Credibility

- Look for specialization in bag making equipment.

- International experience and documented success (e.g., uptime case studies) are positive indicators.

Step 2: Check Certifications and Quality Control

- Confirm certifications like CE and ISO 9001.

- Ask about in-house testing processes (e.g., 72-hour stress test before shipping).

Step 3: Evaluate Customer Support

- Look for responsive communication and technical support.

- Verify availability of services like installation, training, and flexible order quantities.

Conclusion

Non-stretch flat bag making machines are efficient and reliable tools for producing durable, no-frills plastic bags. Choosing the right model involves matching machine specs to production needs and working with a reputable manufacturer for long-term success.

-

Explore this link to understand the functionality and benefits of non-stretch flat bag making machines. ↩