Making lots of plastic bags by hand is slow. It also costs a lot of money. A special machine can solve this problem by making bags quickly and well.

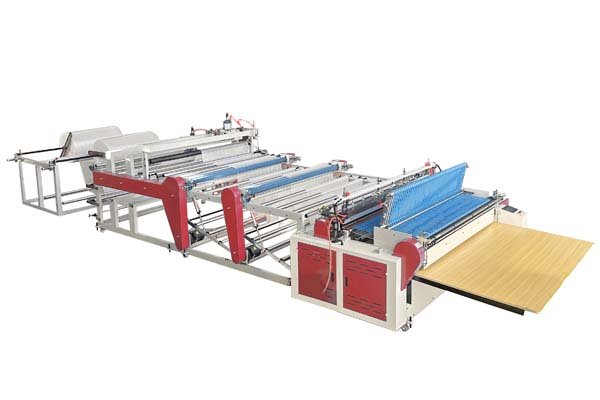

A plastic bag machine1 is an industrial tool. It automatically takes plastic film and turns it into finished bags. This includes cutting, sealing, and sometimes adding handles or other features.

So, these machines are key for businesses that need many plastic bags. At BagMec®, we build these machines to work with different kinds of plastic. This includes common types like LDPE and HDPE. We also work with newer, eco-friendly materials like biodegradable PLA2. The machine feeds the plastic film, shapes it into a bag, and then seals the edges. For some bags, we can add parts like handles, zippers, or gussets to make them more useful.

Our machines make packaging production much easier. They can create many bag types fast. For example, they can make shopping bags you get at a store. Or, they can make bags for food packaging. Some of our machines need a person to help a little. These are semi-automatic. Other machines do almost everything by themselves. These are fully automatic and use smart controls like PLCs and touchscreens. This means less work for people and more bags made every hour.

How does a plastic bag machine actually work?

You know what a plastic bag machine is now. But how does it take a roll of plastic and make a bag? The process has a few important steps.

A plastic bag machine works by first pulling plastic film from a roll. Then, it folds or shapes the film. Next, it uses heat or pressure to seal the sides and bottom. Finally, it cuts the film to separate each bag.

Key Stages in Bag Making

The journey from a simple plastic roll to a finished bag involves several precise actions. Each step is important for the final quality of the bag.

- Film Unwinding and Feeding:

- The process starts with a large roll of plastic film loaded onto the machine.

- The machine carefully pulls the film. At BagMec®, our "Smart Tension Control" system makes sure the film feeds smoothly and evenly. This prevents wrinkles or tears.

- Printing (Optional):

- If the bags need designs or logos, some machines have printing units.

- These units can print before the bag is formed.

- Folding and Gusseting:

- The flat film is then folded to create the bag's basic shape.

- For bags that need to expand, like some shopping bags or stand-up pouches, a gusseting unit creates these folds.

- Sealing:

- This is a critical step. The machine uses heated bars or wires to melt and fuse the plastic edges together. This creates the side seals and the bottom seal.

- The temperature and pressure must be just right for a strong seal. Our machines use precise controls for this.

- Cutting:

- Once sealed, a sharp blade cuts the film to separate individual bags.

- This can be a hot knife, which also seals the cut edge, or a cold knife for a clean cut.

- Stacking or Collection:

- Finally, the finished bags are usually stacked neatly or collected for packaging. Some of our fully automated systems can even count and bundle the bags.

Material Matters

The type of plastic film used affects how the machine is set up.

- LDPE/HDPE/PP films: These are common for shopping bags, garbage bags, and general packaging.

- Biodegradable PLA: For eco-friendly options, machines can be set for PLA, which needs different temperature settings.

- Multi-layer laminates: For food packaging or special pouches, laminated films offer better barrier properties. Our Lamination Pouch Making Machines are designed for these.

Control and Automation Table

Modern machines rely on advanced controls for efficiency and precision.

| Feature | Description | Benefit for You |

|---|---|---|

| PLC Control | A Programmable Logic Controller acts as the brain of the machine. | Ensures consistent operation and easy adjustments. |

| Touchscreen Interface | Allows operators to easily set parameters, monitor production, and troubleshoot. | User-friendly, reduces training time. |

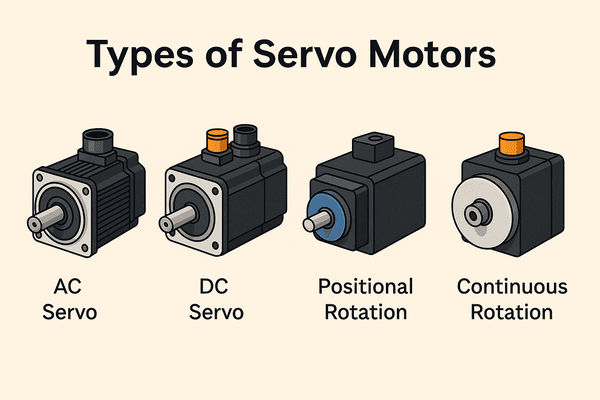

| Servo Motors | Used for precise movement of film and cutting tools. | Increases accuracy, speed, and saves energy (up to 30% with our motors). |

| Sensors | Detect film position, marks for printing, and other critical points. | Reduces errors and material waste. |

What types of plastic bag machines do we offer at BagMec®?

At BagMec®, we know different businesses need different kinds of bags. So, we make a wide variety of machines to meet these specific packaging needs.

We offer many machine types at BagMec®. This includes T-Shirt Bag Machines, Food Package Bag Machines, Heavy Duty Bag Machines, and specialized ones like Wicketer Bread Bag Machines and Courier Bag Machines.

We design each machine to be reliable and efficient for its purpose.

Machines for Everyday Use

These machines produce bags commonly seen in retail and daily life.

- T-Shirt Bag Making Machine3:

- Makes the popular shopping bags with handles, like those from grocery stores.

- Price Range: $17,000 - $32,000 USD.

- Patch Handle Bag Making Machine:

- Creates bags with a reinforced patch handle, often used in boutiques.

- Price Range: $8,500 - $15,500 USD.

- Loop Handle Bag Making Machine:

- Produces bags with soft loop handles, giving a more premium feel.

- Price Range: $33,000 - $38,000 USD.

- Side Sealing Bag Machine:

- Makes simple flat bags or side-gusseted bags, often used for clothes or general items.

- Price Range: $10,500 - $18,500 USD.

Machines for Food and Specialized Packaging

Food safety and specific packaging needs are key here.

- Food Package Bag Machine:

- Designed for various food items, can work with food-grade materials.

- Price Range: $30,000 - $68,000 USD.

- Zipper Bag Making Machine:

- Produces bags with resealable zippers, great for keeping food fresh.

- Price Range: $15,000 - $22,000 USD.

- Lamination Pouch Making Machine:

- Makes pouches from multi-layer laminated films, often for snacks or coffee.

- Price Range: $34,000 - $67,000 USD.

- Wicketer Bread Bag Machine:

- A specialty machine that produces bags on a wicket, used for automated bread packaging.

- Price Range: $69,000 - $88,000 USD.

Machines for Industrial and Heavy-Duty Applications

These machines make strong bags for tougher jobs.

- Garbage Bag Machine:

- Produces trash bags of various sizes, often with drawstrings or star seals.

- Price Range: $23,000 - $35,000 USD.

- Heavy Duty Bag Machine:

- Makes thick, strong bags for industrial goods, agricultural products, or construction waste.

- Price Range: $12,000 - $23,000 USD.

- Courier Bag Machine / DHL Multifunction Bag Making Machine:

- Creates durable bags for shipping and logistics, often with adhesive strips and document pouches.

- Price Range: $23,000 - $35,000 USD.

- Diaper Bag Making Machine:

- Specialized for producing bags for diaper packaging, focusing on hygiene and efficiency.

- Price Range: $25,000 - $70,000 USD.

- FFS (Form-Fill-Seal) Bag Machine:

- These advanced machines form the bag, fill it with product, and seal it, all in one continuous process.

- Price Range: $34,000 - $48,000 USD.

We also offer custom features like logo embossing and precision die-cutting. Our machines use high-carbon steel parts and corrosion-resistant coatings for long life.

Why choose a BagMec® machine for your plastic bag production?

You have choices when buying a plastic bag machine. So why should you consider BagMec®? We believe our machines and service offer real advantages.

Choosing BagMec® means you get reliable, customized machines with modern technology like "Smart Tension Control." We also provide strong quality checks, energy-saving designs, and excellent global support for your business.

Let's explore what makes us a good partner for your production needs.

Our Focus on Quality and Innovation

We build our machines to last and perform well.

- Certifications: Our Wenzhou facility is ISO 9001 certified. Our machines meet CE Compliance and Energy-efficient Design Standards. This shows our commitment to quality.

- Patented Technologies: We develop our own tech. Our "Smart Tension Control" helps feed film smoothly. Our energy-saving servo motors can cut power use by 30%.

- Durability: We use high-carbon steel parts. We also apply corrosion-resistant coatings. This is especially good for machines in humid places.

- 5-Stage Inspection: Every machine goes through:

- Material hardness testing.

- Precision alignment checks with lasers.

- A 72-hour continuous operation stress test.

- Safety compliance checks (like emergency stops).

- Pre-shipment validation after disassembly and reassembly.

Tailored Solutions for Your Industry

We understand that different industries have different needs.

- Retail & E-commerce: We offer high-speed shopping bag machines that can make up to 1,200 bags per hour.

- Food Safety: Our food packaging systems are FDA-compliant. They have anti-contamination designs.

- Logistics: Our courier bag machines make strong, tear-resistant seams. Some can print QR codes.

- Medical & Hygiene: We have aseptic diaper bag production lines. Carlos Mendez from Mexico needed an aseptic diaper bag machine with ISO 13485 compliance, which we can provide.

Partnership and Support

We want to be more than just a supplier.

- End-to-End Expertise: Our teams for R&D, production, and after-sales work together. This makes your project go smoothly.

- Flexible MOQs: We accept prototype orders for just one machine. We can also handle large bulk orders.

- Global Logistics: We deliver machines in about 45 days. For repeat orders, we can do it in 25 days. We offer on-site installation and training if you need it. We handle trade terms like EXW, FOB, CIF, and DDP.

- Sustainability: Our machines are designed to work well with recycled and biodegradable materials. We also have carbon-neutral assembly plans. An eco-brand in the US worked with us to develop machines for 100% compostable PLA shopping bags.

Priya Kapoor in India, founder of an e-commerce startup, needed a compact courier bag machine under $50,000. She was also worried about technical support. We can meet these needs with our machines and reliable service.

Conclusion

A plastic bag machine automates making various bags from film. BagMec® offers many types, focusing on quality, innovation, and great support. Choosing the right machine means understanding your specific bag needs and production goals. We are here to help you.

-

Explore this link to understand the technology behind plastic bag machines and their impact on packaging efficiency. ↩

-

Learn about biodegradable PLA materials and their eco-friendly advantages for sustainable packaging solutions. ↩

-

Discover the functionality and benefits of T-Shirt Bag Making Machines for efficient bag production. ↩