Plastic bags are everywhere, right? But this convenience hides a big environmental headache. It's a problem that touches us all, from our oceans to our own health.

The biggest issue with plastic bags is their refusal to truly disappear. They linger for centuries in the environment, breaking down into tiny, harmful microplastics that pollute ecosystems and threaten wildlife.

These bags don't biodegrade like an apple core or a leaf. Instead, sunlight and physical forces shred them into smaller and smaller pieces. This process creates countless microplastic particles. These tiny bits then spread easily. They get into our soil, our water sources, and even the air we breathe. It's like a slow, silent invasion. The huge number of bags we produce and use every single day makes this a massive challenge for our planet's health, and potentially our own.

Let's look at why this is so concerning:

- Harm to Wildlife: Animals often mistake plastic pieces, big or small, for food. This can lead to internal blockages, starvation, or poisoning as toxins leach from the plastic. Seabirds, turtles, and marine mammals are especially vulnerable.

- Ecosystem Contamination: Microplastics act like tiny sponges, soaking up pollutants from their surroundings. When they enter the food chain, these concentrated toxins can move up, affecting more and more animals, and eventually, us.

- Persistence: Most common plastics can take hundreds, even thousands, of years to decompose fully. This means every plastic bag ever made, unless incinerated, still exists in some form.

How Can Manufacturers Address the Plastic Bag Problem?

So, we know plastic bags are a serious issue. But what can we, as manufacturers in the bag-making industry, actually do? It’s not just about identifying the problem; it’s about actively finding and promoting workable answers.

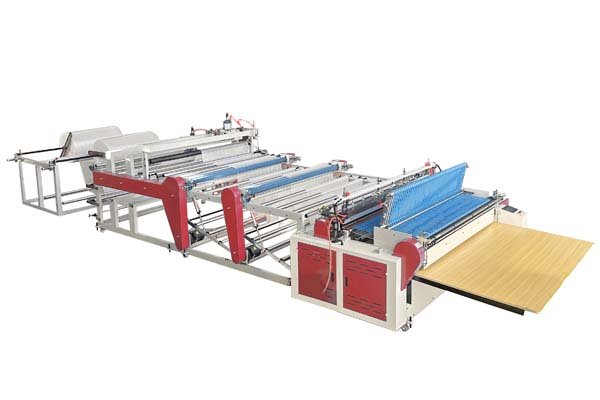

Manufacturers can address the plastic bag problem by investing in machinery that processes eco-friendly materials, designing for durability and recyclability, and reducing waste in the production process itself.

As a company, BagMec® believes we have a crucial role. It's not just about making machines; it's about making machines that contribute positively. We focus on innovation that allows our clients to produce bags that are less harmful to the environment. This involves looking at the entire lifecycle of a bag.

Our Approach at BagMec®

We believe a multi-faceted approach is needed from machinery manufacturers like us. Here’s how we’re tackling it:

1. Engineering for Sustainable Materials

The type of material a bag is made from is critical.

- Biodegradable Options: We’ve ensured many of our machines, like the T-Shirt Bag Making Machine (priced from $17,000) and our Food Package Bag Machines (from $30,000), are fully compatible with biodegradable materials like PLA (Polylactic Acid). This means our clients can produce bags that can break down under the right composting conditions.

- Recycled Content: Our machines are also designed to handle films with high percentages of recycled content. This helps reduce reliance on virgin plastics. For instance, our Garbage Bag Machines ($23,000-$35,000) are often used with recycled LDPE/HDPE.

| Material Feature | Conventional PE/PP | Biodegradable PLA | Recycled PE/PP |

|---|---|---|---|

| Feedstock Source | Fossil Fuels | Plant-based (corn) | Post-consumer |

| End-of-Life | Landfill/Recycle | Industrial Compost | Recycle |

| BagMec® Machine Use | High Compatibility | High Compatibility | High Compatibility |

2. Optimizing Machine Efficiency for Less Waste

Waste isn't just bad for the environment; it's bad for business.

- Precision Engineering: Our "Smart Tension Control" technology is a great example. It ensures consistent film feeding, which significantly reduces material waste during production. This is a standard feature on high-speed lines like our Wicketer Bread Bag Machine ($69,000-$88,000).

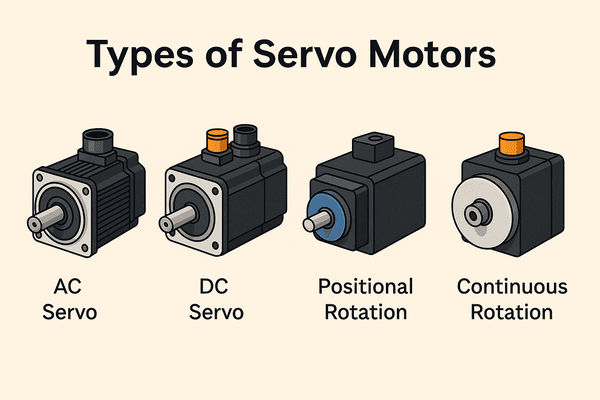

- Energy Savings: We use energy-saving servo motors in many of our designs. These can reduce power consumption by up to 30%. This lowers the carbon footprint of bag production and saves our clients money on operational costs.

3. Designing for Durability and Reusability

Not all bags need to be single-use.

- Stronger Bags: Machines like our Heavy Duty Bag Machine ($12,000-$23,000) and Loop Handle Bag Making Machine ($33,000-$38,000) produce bags that are robust enough for multiple uses. When a bag can be reused many times, it drastically cuts down on the number of new bags needed.

- Specialty Applications: Our Courier Bag Machines ($23,000-$35,000) produce bags with tear-resistant seams, vital for logistics. While often single-use for security, their durability ensures goods are protected, reducing damage and the need for re-shipment (and more packaging).

Are Biodegradable Bags a Perfect Solution?

We hear a lot about "biodegradable" as a fix. It sounds great, doesn't it? But are these bags the magic bullet we're hoping for? Let's look closer at what this means for our environment and our industry.

Biodegradable bags can be a good alternative to conventional plastics if they are made from genuinely compostable materials like PLA and are disposed of in proper industrial composting facilities where they can fully break down.

It’s important to understand the nuances here. Not all "biodegradable" claims are equal, and the end-of-life management is key. As a machinery provider, we want to ensure our clients who choose this path are well-informed.

Understanding Biodegradable Bags

The term "biodegradable" can sometimes be misleading if not properly qualified. Here’s what to consider:

1. What Makes a Bag Truly Biodegradable or Compostable?

- Material Matters: True compostable bags, like those made from PLA, are designed to break down into natural elements (carbon dioxide, water, biomass) in a controlled composting environment. This is different from some "oxo-degradable" plastics, which simply fragment into smaller plastic pieces (microplastics) and don't fully disappear.

- Certifications: Look for certifications like ASTM D6400 (US) or EN 13432 (Europe). These standards ensure a product will biodegrade effectively under specific composting conditions. At BagMec®, our machines that process PLA, like the Lamination Pouch Making Machine ($34,000-$67,000) when used for laminated biodegradable films, are built to handle these advanced materials precisely.

2. The Importance of Composting Infrastructure

This is a big one.

- Industrial Facilities: Most certified compostable plastics require industrial composting facilities. These facilities maintain the specific temperature, moisture, and microbial conditions needed for proper decomposition. Simply putting a PLA bag in your backyard compost bin or, worse, in a landfill, often won't lead to the desired breakdown. In a landfill, it might still persist for a long time due to lack of oxygen.

- Consumer Awareness: Consumers need to know how to dispose of these bags correctly. Clear labeling and public education are vital.

3. BagMec® and Biodegradable Solutions

We are committed to supporting the shift towards more sustainable options.

- Machine Adaptability: Our R&D focuses on ensuring our machines, from Side Sealing Bag Machines ($10,500-$18,500) to complex FFS (Form-Fill-Seal) Bag Machines ($34,000-$48,000), can be configured to work efficiently with various biodegradable and compostable films.

- Client Consultation: We work with clients like the US Eco-Brand mentioned in our case studies. They co-developed biodegradable PLA film machines with us, enabling 100% compostable shopping bags. This kind of partnership is key.

So, while biodegradable bags aren't a standalone perfect fix for all plastic problems, they represent a significant step forward, especially when produced on reliable machinery and disposed of correctly.

How Does BagMec® Specifically Support Sustainable Bag Production?

We've talked about the problems and some general solutions. But how do we at BagMec® tangibly help our clients produce more sustainable bags? It's about more than just selling a machine.

BagMec® supports sustainable bag production by offering customized machinery for eco-materials, focusing on energy-efficient designs, providing robust quality control for long machine life, and sharing our expertise in future-ready technologies.

Our goal is to empower businesses to make a positive environmental impact while still meeting their production needs. We see sustainability and efficiency as going hand-in-hand.

BagMec's Commitment in Action

Here’s a closer look at our specific contributions:

1. Customized Machinery for Eco-Materials

Every client's needs are different.

- Material Versatility: We don't just offer off-the-shelf solutions. Our core capability is Customized Machinery Solutions. Whether a client needs a Patch Handle Bag Making Machine ($8,500-$15,500) for LDPE or a specialized Diaper Bag Making Machine ($25,000-$70,000) for multi-layer aseptic films, we can adapt. This includes optimizing for PLA, recycled PP, or other innovative materials.

- Feature Integration: We can add custom features like logo embossing or precision die-cutting, ensuring that even eco-friendly bags meet brand and functional requirements.

2. Energy Efficiency and Reduced Waste

Sustainability is built into our machine design.

- Patented Technologies: Our "Smart Tension Control" not only ensures film feeding consistency for quality but also minimizes material scrap.

- Servo Motor Advantage: As mentioned, our energy-saving servo motors cut power use by up to 30%. This is a direct contribution to a lower carbon footprint per bag produced. For example, a high-output T-Shirt Bag Making Machine ($17,000-$32,000) running with these motors makes a big difference over a year.

- Durability Assurance: Our machines are built with high-carbon steel components and corrosion-resistant coatings. This means they last longer, reducing the need for frequent replacements and the associated manufacturing footprint.

3. Future-Ready Technology and Support

We help our clients stay ahead.

- IoT Enablement: Many of our newer systems are IoT-enabled. This allows for remote diagnostics and even predictive maintenance, minimizing downtime and ensuring machines run at peak efficiency.

- Expert Consultation: We provide end-to-end expertise, from R&D to after-sales. If Priya Kapoor from India needs a compact courier bag machine under $50,000 with good technical support, or Hans Fischer from Germany needs a high-speed zipper bag machine meeting EU standards, we are here to guide them.

4. Focus on Industry-Specific Green Solutions

Different industries have different needs.

- Food Safety & Eco Packaging: Our Food Package Bag Machines can be configured for FDA-compliant systems using biodegradable laminates.

- Retail Solutions: High-speed shopping bag machines capable of using recycled or PLA materials for retail chains aiming for zero-waste.

By focusing on these areas, we aim to be more than just a supplier; we aim to be a partner in our clients' journey towards more sustainable packaging.

Conclusion

The problem with plastic bags is serious, impacting our environment deeply. But we have ways to fight back, from using less to choosing better materials and smarter production. At BagMec®, we're dedicated to providing machinery that supports these sustainable choices for a cleaner future.