Are you trying to figure out the budget for a new garbage bag machine1? The wide range of prices can be confusing. This uncertainty makes planning difficult and could delay your smart investment. We will break down the costs for you. This will help you make a confident and well-informed decision for your business.

A garbage bag machine from us at BagMec® generally costs between $23,000 and $35,000. The final price depends on the machine's production speed, level of automation, and any special features you need for your manufacturing line.

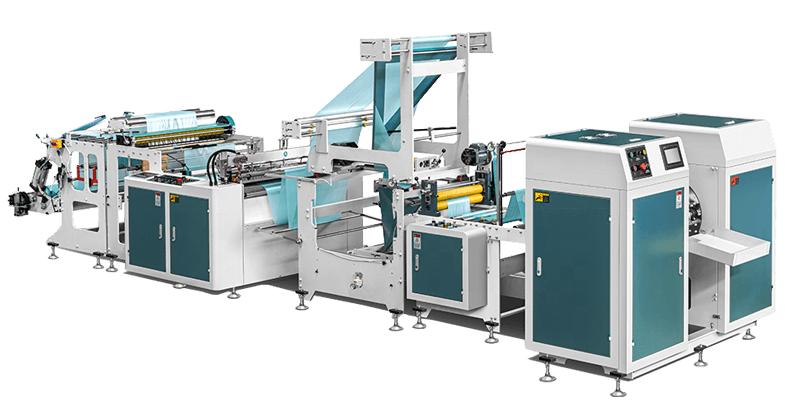

This price range covers a variety of models. A basic, semi-automatic machine will be at the lower end of this scale. It is a great starting point for new businesses or smaller production runs. A fully automated, high-speed machine will be at the higher end. These machines include advanced features like automatic roll changing and PLC touch-screen controls. They are built for large-scale operations where efficiency and low labor costs are most important. We help you choose the right configuration. This ensures you only pay for the capabilities that directly benefit your production goals.

When you look at our machines, you are seeing a spectrum of capabilities. A machine at the $23,000 mark is a strong, reliable workhorse. It is perfect for producing standard garbage bags with minimal fuss. As you move toward the $35,000 price point, you add significant automation. This includes systems that reduce waste, like our "Smart Tension Control," and features that increase output, like a high-speed sealing bar. We design each machine to provide the best value for its price.

What Factors Determine the Final Price of a Garbage Bag Machine?

Many details add up to the final price tag of a machine. Let's look at the most important ones to understand your investment.

The final price is mainly set by the machine's automation level2, its production capacity3 (bags per minute), the materials it can handle (like LDPE, HDPE, or biodegradable films), and any custom add-ons like printing units or special sealing systems.

These factors are not just about adding features. They are about building a machine that fits perfectly into your production line and meets your business goals. A startup might prioritize a lower initial cost. A large manufacturer might focus on high speed and automation to get a better long-term return on investment.

Key Cost Factors

Let's break down each element. This will give you a clear picture of how your machine's price is calculated.

1. Automation Level: Semi-Automatic vs. Fully-Automatic

The level of automation is one of the biggest price drivers.

- Semi-Automatic Machines: These are at the lower end of our price range. They require an operator to handle tasks like loading film rolls and removing finished bags. They are a great, cost-effective option for businesses with smaller production demands or available labor.

- Fully-Automatic Machines: These machines cost more upfront. They have advanced PLC controls and touchscreen interfaces. They can run continuously with minimal human supervision. The long-term savings on labor costs and reduced human error often provide a quick return on the higher initial investment.

2. Production Capacity and Speed

How many bags do you need to make per hour? The answer directly impacts the cost.

- Higher Speed, Higher Cost: A machine that produces 200 bags per minute needs more advanced components than one that produces 100. This includes more powerful, energy-saving servo motors and more durable mechanical parts that can handle the increased speed and stress.

- Our Technology: We use patented technologies like "Smart Tension Control." This system ensures consistent film feeding even at high speeds. This reduces material waste and a machine that runs smoothly without frequent stops.

3. Material Compatibility

The type of plastic film you use matters.

- Standard Films (LDPE/HDPE): Most of our machines are optimized for these common materials right out of the box.

- Biodegradable Films (PLA): As you can see from our case study with a US Eco-Brand, we are experts in machines for sustainable materials. PLA films are more sensitive to heat and tension. Machines built for them require more precise temperature control systems and gentle handling mechanisms, which can add to the cost.

4. Custom Add-Ons and Features

We can customize your machine with a range of special features. Each one will adjust the final price. Here is a look at some common options:

| Feature | Impact on Cost | Why It Matters for Your Business |

|---|---|---|

| In-Line Printing Unit | Moderate to High | Allows you to print logos or branding directly onto the bags during production. |

| Coreless Winding Unit | Moderate | Creates rolls of bags without a central cardboard core, saving on material costs. |

| Drawstring Insertion | High | Adds a complex module to automatically insert and seal drawstrings into bags. |

| Heavy-Duty Sealing Bar | Low to Moderate | Necessary for making thick, industrial-strength bags that require a stronger seal. |

| Multi-Language UI | Low | Makes the machine easier to operate for teams in different regions. |

How Does Automation Impact the Machine's Cost and Your ROI?

Automation is more than a feature. It is a business strategy. The upfront cost is higher, but the long-term payoff can be huge.

A higher level of automation increases the initial machine cost but cuts long-term operational expenses. A fully automated system needs less labor, lowers material waste, and boosts output. This leads to a faster and bigger return on investment (ROI).

Think of automation as an investment in efficiency. You are paying more at the start to save much more over the life of the machine. For many of our clients, like the German packaging supplier who achieved 99% uptime, the decision to automate was key to their success.

Calculating the Value of Automation

Let's look at the numbers and see how automation pays for itself.

The Upfront Cost of Automation

A fully-automated garbage bag machine from us includes a sophisticated PLC control system with a user-friendly touchscreen. It also has sensors that monitor the entire process, from film unwinding to the final stacking of bag rolls. These high-tech components are what push the price towards the $35,000 mark. They are built for precision and reliability.

Long-Term Savings and ROI

Here is where you see the return on that initial investment.

- Reduced Labor Costs: A semi-automatic line might need two operators. A fully automated line can often be managed by one supervisor monitoring multiple machines. This is a direct and significant saving on your monthly payroll.

- Lower Material Waste: Our automated systems, with features like "Smart Tension Control," ensure every bag is made to spec. There are fewer rejects from improper seals or cuts. The 18% reduction in material waste seen by our German client is a typical example of this benefit.

- Increased Uptime and Output: Automated machines are designed for 24/7 operation. They don't get tired. This means you can produce more bags in the same amount of time, allowing you to take on larger orders and grow your business faster.

Automation Level Cost-Benefit Analysis

| Feature | Semi-Automatic Machine | Fully-Automatic Machine |

|---|---|---|

| Initial Cost | Lower (Closer to $23,000) | Higher (Closer to $35,000) |

| Labor Needs | 1-2 operators per machine | 1 supervisor for multiple machines |

| Material Waste Rate | Higher (due to manual adjustments) | Lower (precision control reduces errors) |

| Typical ROI Period | 24-36 months | 12-18 months |

| Best For | Startups, small to medium batches | High-volume industrial producers |

What Hidden Costs Should I Consider When Buying a Machine?

The price on the quote is the biggest part of your investment, but it is not the only part. We believe in being transparent so you can create a complete and accurate budget.

Beyond the machine's sticker price, you should budget for shipping, installation, and training. Also, think about ongoing costs like spare parts, maintenance, and power consumption. We offer clear trade terms like FOB and CIF to help you see these costs upfront.

Planning for these additional costs from the beginning will prevent surprises. It ensures a smooth process from our factory to your production floor. Our team is here to help you understand every line item.

A Complete Budget Breakdown

Let's explore these other costs in more detail so you can plan effectively.

1. Shipping and Logistics

Your machine has to get from our factory in Wenzhou, China, to your facility. We offer several options to fit your needs and budget.

- Trade Terms: We work with standard international trade terms.

- FOB (Free On Board): We cover the cost of getting the machine to the port in China. You handle the sea freight, insurance, and import duties.

- CIF (Cost, Insurance, and Freight): We manage the shipping and insurance to a port in your country. You are responsible for import clearance and transport from the port to your factory.

- DDP (Delivered Duty Paid): We can handle the entire process for you, delivering the machine directly to your door with all duties paid. This is the most hassle-free option.