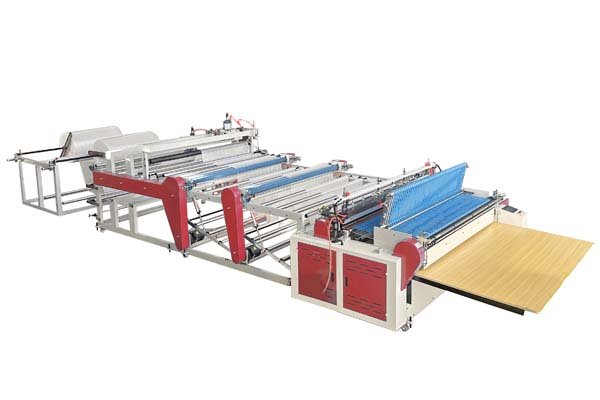

Trying to figure out the cost of an LD bag machine1 can be tricky. This uncertainty makes planning hard. You need clear information to make a good investment for your business.

An LD (Low-Density Polyethylene) bag machine can cost between $8,500 and $18,500 USD. The final price depends on its specific type, features, level of automation, and the production capacity you need.

This price range gives you a general idea. But many things can change the final cost of an LD bag machine. For example, a simple side-sealing machine or a patch handle machine will have different price points. Also, how automated the machine is – from semi-automatic to fully automatic – plays a big role. Plus, the speed you need and any special features will affect the price. At BagMec®, we offer machines like our Patch Handle Bag Making Machine, which ranges from $8,500 to $15,500, and our Side Sealing Bag Machine, priced between $10,500 and $18,500.

When we talk about LD bag machines, we're often looking at equipment designed for versatility and efficiency. These machines typically handle LDPE films, but many, like ours, are also compatible with HDPE/PP films and even biodegradable PLA. The complexity of the machine, such as if it includes features like logo embossing units or uses our patented "Smart Tension Control" for consistent film feeding, will naturally influence the investment required. We always aim to provide a machine that offers the best value for your specific production needs.

What factors influence the LD bag machine price the most?

Many things affect the final price tag of an LD bag machine. It's good to know these factors. This helps you understand what you're paying for and choose the best machine.

The main factors influencing an LD bag machine's price are its type (e.g., side seal, T-shirt bag), automation level2 (semi to full), production speed, build quality, material compatibility (LDPE, PLA), and any custom features3 like printing or special die-cutting units.

Let's dive deeper into these elements. Each one contributes to the overall value and cost.

Machine Type and Complexity

The kind of bag the machine produces is a primary cost driver.

- A basic Side Sealing Bag Machine ($10,500-$18,500) for simple flat bags is generally less complex.

- A T-Shirt Bag Making Machine ($17,000-$32,000) involves more processes like handle punching, so it costs more.

- Specialty machines like our Wicketer Bread Bag Machine ($69,000-$88,000) are highly specialized and thus command a higher price.

Our range includes machines for shopping bags, food-grade packaging, and heavy-duty industrial bags, each with varying complexity.

Automation Level

How much human help the machine needs impacts its price.

- Semi-automatic machines are less expensive upfront. They require more operator involvement.

- Fully automated systems, featuring PLC control and touchscreen interfaces, cost more. But they reduce labor costs and can increase output significantly. Many of our BagMec® machines offer high automation.

Production Capacity and Speed

The faster and more bags a machine can produce, the higher its price.

- A machine producing 100 bags per minute will cost less than one producing 300 bags per minute.

- Our retail and e-commerce solutions include high-speed shopping bag machines capable of 1,200 bags/hour. This kind of performance is an investment in efficiency.

Build Quality and Innovative Engineering

The materials and technology used in construction are key.

- Using high-carbon steel components makes a machine more durable. This adds to the cost but also to the lifespan.

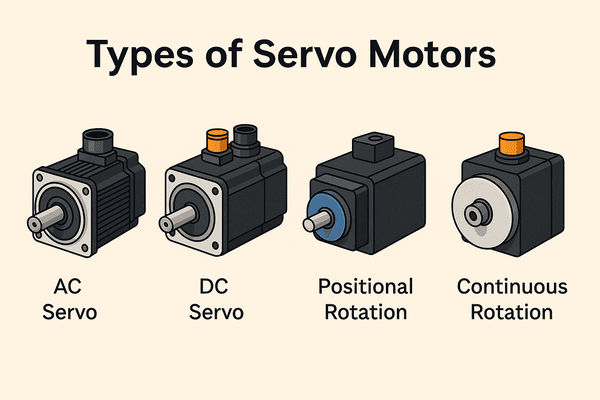

- Patented technologies, like our "Smart Tension Control" for film feeding or energy-saving servo motors (reducing power use by 30%), add value and affect price.

- Our machines are built at our ISO 9001 certified facility in Wenzhou, ensuring quality.

Custom Features and Material Compatibility

Any additions beyond standard specifications will influence the price.

- Custom features like logo embossing units, precision die-cutting, or multi-language User Interfaces add to the cost.

- If a machine needs to handle diverse materials like LDPE/HDPE/PP films, biodegradable PLA, or multi-layer laminates, it may require special components, affecting price. BagMec® machines are designed for broad material compatibility.

Here's a simple table to illustrate:

| Feature | Basic LD Machine | Advanced BagMec® LD Machine | Impact on Price |

|---|---|---|---|

| Automation | Semi-Automatic | Fully Automatic (PLC) | Significant |

| Speed (Bags/Hour) | Lower (e.g. 3000) | Higher (e.g. 7200+) | Significant |

| Custom Add-ons | None | Embossing, Special Dies | Moderate |

| Innovative Tech | Standard Motors | Servo Motors, Smart Tension | Moderate |

| Build Material | Standard Steel | High-Carbon Steel | Moderate |

Are cheaper LD bag machines worth it in the long run?

It's always tempting to go for the lowest price. But when buying an LD bag machine, is "cheaper" really better? Let's look at this.

Cheaper LD bag machines might save money initially. However, they could lead to higher long-term costs due to more frequent maintenance, lower output quality, shorter operational life, and less robust support.

When you think about buying a machine, consider the total cost of ownership, not just the purchase price.

Quality of Components and Construction

- Lower-priced machines might use components that wear out faster. This means more downtime and replacement costs.

- We use high-carbon steel and corrosion-resistant coatings. This ensures our BagMec® machines are durable, even in humid environments. Our 5-stage inspection protocol, including a 72-hour continuous operation stress test, backs this up.

Efficiency and Performance

- A cheaper machine might not produce bags as consistently or quickly. This can reduce your overall productivity.

- Our machines, with features like "Smart Tension Control" and energy-saving servo motors, are designed for efficiency. For example, a German packaging supplier using our FFS bag machines achieved 99% uptime and cut material waste by 18%.

Support and Reliability

- What kind of after-sales support can you expect with a very low-cost machine?

- We provide global logistics support, including optional on-site installation and training. This is part of our commitment. Priya Kapoor, an e-commerce founder in India, highlighted the challenge of limited technical support from previous vendors – a problem we strive to solve.

Scalability and Future Needs

- A basic machine might meet your needs today. But what about tomorrow?

- Our machines, including IoT-enabled options for remote diagnostics, are built with an eye on future-ready technology. This ensures your investment can grow with your business.

So, while a cheaper machine looks good on paper, a quality machine from a reputable manufacturer like BagMec® often provides better value and peace of mind over its lifespan.

How can I get a specific quote for an LD bag machine from BagMec®?

Getting an exact price for an LD bag machine tailored to your needs is a clear process with us. You just need to give us some details.

To get a specific quote, contact us at BagMec® with your requirements. Tell us the bag type, size, material, desired production speed, and any special features. We offer a free consultation and will provide a detailed quote within 48 hours.

Here's how we make it easy for you:

Step 1: Reach Out to Us

- You can contact our General Manager, Joshua Wei, directly.

- Email us at info@bagmec.com.

- Or, visit our website at www.bagmec.com. It's available in English, Chinese, and Spanish.

Step 2: Provide Your Specifications

The more details you give us, the more accurate your quote will be. Think about:

- Type of Bag: Are they simple LDPE bags, T-shirt bags, patch handle bags, side-seal bags?

- Material: LDPE is common, but perhaps you need HDPE, PP, or biodegradable PLA.

- Bag Dimensions: Length, width, and any gussets.

- Production Volume: How many bags do you need to make per hour or per day?

- Automation: Do you prefer a semi-automatic or a fully automated line?

- Special Features: Do you need printing units, embossing, or unique die-cuts?

Step 3: Free Engineering Consultation

- We offer a free engineering consultation. This helps us understand your needs perfectly.

- We can discuss our machine capabilities, like our "Smart Tension Control" or energy-efficient designs.

- You can even schedule a virtual factory tour of our Wenzhou facility.

Step 4: Receive Your Custom Quote

- Once we have all your information, our team will prepare a comprehensive quote.

- We guarantee you'll receive this quote within 48 hours.

- The quote will include the machine price, technical specifications, and available trade terms (EXW, FOB, CIF, DDP).

- We also offer flexible MOQs, even accepting prototype orders for 1 machine. Standard delivery is typically 45 days.

This process ensures you get a clear and precise price for the LD bag machine that fits your business perfectly.

Conclusion

The price of an LD bag machine, typically $8,500-$18,500+, varies by type, automation, and features. Choosing quality from a trusted maker like BagMec® ensures long-term value. Contact us for a precise quote tailored to your needs.

-

Understanding the average cost of LD bag machines helps in budgeting and making informed investment decisions for your business. ↩

-

Exploring how automation impacts pricing can guide you in selecting the right machine for your production needs and budget. ↩

-

Learning about the advantages of custom features can help you enhance your production efficiency and product quality. ↩