Are you finding it hard to get the film properties you need? The wrong blow-up ratio (BUR)1 can lead to weak, inconsistent film, wasting your materials and time. Understanding the right BUR for each polymer is your first step towards top-quality film production.

The ideal blow-up ratio (BUR) varies by polymer. Generally, for LDPE, aim for 2:1 to 3.5:1. LLDPE often uses 2:1 to 4:1. HDPE, especially HMW-HDPE, needs higher BURs, like 3.5:1 to 5.5:1. For PLA, try 2.5:1 to 3.5:1, while PBAT or PBAT/PLA blends often perform well around 2.8:1.

The blow-up ratio is a critical parameter in blown film extrusion. It directly influences the molecular orientation2 of your film. When you inflate the plastic bubble, you're stretching the polymer chains in the transverse direction (TD). This stretching aligns the molecules, which in turn determines many of the film's final characteristics. Getting the BUR right helps you balance properties like tensile strength in both machine direction (MD) and TD, impact strength, tear resistance, and even clarity. It's not just a setting; it's a fundamental control over your film's performance.

Different materials have different molecular structures and melt strengths. This means they respond differently to the stretching process. For instance, LDPE, with its branched structure, is quite forgiving and can produce stable bubbles over a decent BUR range. LLDPE, with its linear structure, requires more careful control but can yield excellent toughness when optimized. HDPE films often require higher BURs to achieve good stiffness and barrier properties. Bioplastics like PLA are more sensitive, and controlling BUR precisely is key to avoiding brittleness and achieving useful film properties.

How Does Blow-Up Ratio Directly Impact Your Film's Strength and Clarity?

You've got the general BUR numbers, but what exactly happens to your film when you adjust this ratio? Let's look at how BUR concretely affects critical film qualities like strength and visual appearance.

A higher BUR generally boosts Transverse Direction (TD) strength and can improve film clarity by better aligning polymer chains. However, an excessively high BUR might unbalance strength by weakening the Machine Direction (MD) or lead to bubble instability and processing issues.

When we talk about BUR, we're really discussing how much we stretch the molten plastic tube sideways compared to its original die diameter. This stretching has profound effects.

Molecular Orientation and Anisotropy

The primary effect of BUR is on molecular orientation.

- Low BUR: Less radial stretching. This can result in film that is stronger in the machine direction (MD) if the draw-down ratio is high, but weaker in the transverse direction (TD).

- High BUR: More radial stretching. This increases orientation in the TD, boosting TD strength and stiffness. However, if BUR is too high, it can lead to an imbalance, making the film too weak in the MD or prone to splitting.

- Balanced BUR: The goal is often to achieve a balance between MD and TD properties. This "isotropic" behavior is desirable for many applications where strength is needed in multiple directions, like general-purpose bags.

Impact on Key Film Properties

Let's break down how BUR influences specific properties:

| Property | Low BUR Effect | Optimal BUR Effect | High BUR Effect (Potentially Excessive) |

|---|---|---|---|

| TD Strength | Lower | Balanced or High | Very High (can reduce MD strength) |

| MD Strength | Potentially Higher (relative to TD) | Balanced | Lower (if TD is over-oriented) |

| Clarity | Can be lower due to less uniform orientation | Often Improves as orientation aligns | May decrease if bubble is unstable |

| Tear Resistance | Can be more directional | Generally more balanced performance | Can be very directional, risk of splitting |

| Impact Strength | May be reduced, especially in TD | Often improved due to better orientation | Can decrease if film becomes too stiff |

| Stiffness | Lower in TD | Increases, especially in TD | Can become very stiff, potentially brittle |

Practical Examples

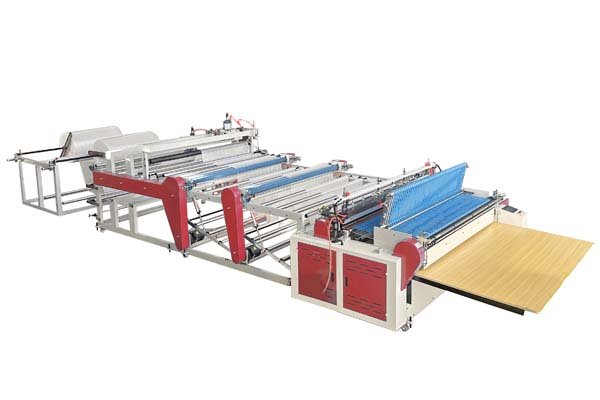

- Shopping Bags: We often want good TD strength for these, as this is the direction that bears the load when the bag is carried. A moderate to high BUR helps achieve this. Our T-Shirt Bag Making Machines and Loop Handle Bag Making Machines are designed to work with films optimized for such strength.

- Heavy Duty Bags: For applications like our Heavy Duty Bag Machine produces, a balance of MD and TD strength is crucial to prevent tearing and punctures under load. Proper BUR helps achieve this toughness.

- Food Packaging Films: Clarity can be very important here. An optimal BUR helps align polymer chains in a way that minimizes light scattering, improving transparency. Our Food Package Bag Machines rely on films with good clarity and barrier properties.

Getting this right means your film performs as intended, whether it's for a sturdy garbage bag or a clear food wrap.

Beyond Material Type: What Other Factors Influence the Ideal Blow-Up Ratio?

While the polymer is a huge factor, it's not the only thing that dictates your BUR setting. Several other machine and process variables come into play. Let's explore these.

Beyond the polymer, factors like die gap size3, cooling air efficiency, melt temperature, frost line height (FLH), take-up speed (draw-down ratio), and the specific end-use application requirements significantly influence the optimal blow-up ratio for your film production.

Achieving the perfect film isn't just about picking the right material and a textbook BUR. It's a dynamic process where several elements interact.

Machine and Process Parameters

These are settings and conditions you can often control on your extrusion line:

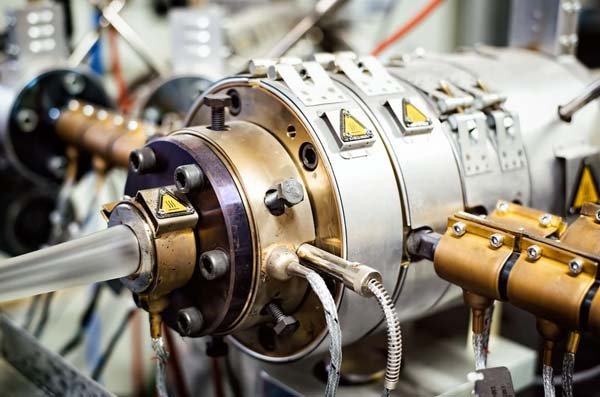

- Die Gap: The initial thickness of the molten tube exiting the die.

- A smaller die gap might necessitate a higher BUR to achieve the desired film thickness and width.

- A larger die gap might allow for a lower BUR for the same final dimensions.

Our BagMec® machines offer various die options to suit different needs.

- Cooling System Efficiency: How quickly and evenly the bubble is cooled.

- Efficient air rings and internal bubble cooling (IBC) systems allow for more stable bubbles, especially at higher BURs or with faster line speeds. This is crucial for materials like HDPE or for high-output lines.

- Melt Temperature: The temperature of the polymer as it exits the die.

- Higher melt temperatures generally reduce melt viscosity and strength, which can make it harder to maintain a stable bubble at high BURs.

- Lower melt temperatures increase melt strength but can also lead to processing issues if too low.

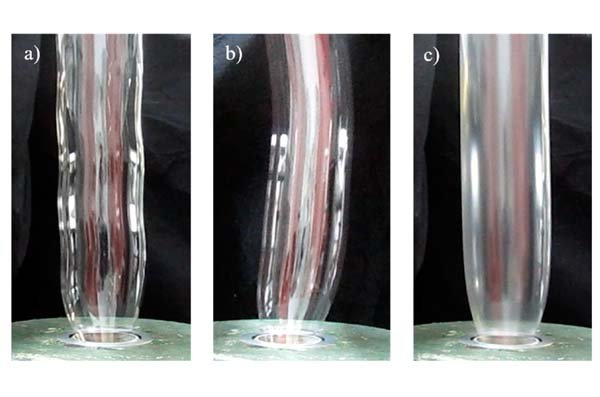

- Frost Line Height (FLH): The point where the molten plastic solidifies.

- A higher FLH gives the polymer more time to orient in its molten state, which can interact with the BUR to affect final properties. A lower FLH means faster solidification. Controlling FLH is key for bubble stability.

- Draw-Down Ratio (DDR) / Take-Up Speed: The ratio of how much the film is stretched in the machine direction.

- While BUR controls TD orientation, DDR controls MD orientation. These two must be balanced. A high DDR with a low BUR will result in a film highly oriented in the MD.

Additives and Blends

What you put into your base resin also matters:

- Processing Aids: Can alter melt viscosity and reduce die build-up, potentially allowing for smoother processing at different BURs.

- Fillers (e.g., Calcium Carbonate): Can increase stiffness but may limit the achievable BUR or affect bubble stability.

- Colorants and Other Additives: Some pigments or additives can affect heat absorption or melt properties, indirectly influencing the stable BUR range.

- Polymer Blends: Blending polymers, like LDPE with LLDPE, creates a material with combined characteristics. The optimal BUR for a blend will likely be different from that of the individual components.

Desired Film Application Needs

The end-use of your film dictates the target properties, which in turn influences BUR:

- Shrink Films: Often require a specific orientation balance to achieve desired shrink characteristics in TD and MD.

- Lamination Films: Need good flatness and dimensional stability, which a well-controlled BUR contributes to. Our Lamination Pouch Making Machines benefit from such high-quality films.

- Barrier Films: For food or medical packaging, specific orientation can enhance barrier properties. This is relevant for our Zipper Bag Making Machines or specialized food packaging lines.

As you can see, setting the BUR is part of a larger optimization puzzle.

How Can Advanced Machinery Like BagMec's Help You Master Blow-Up Ratios?

Knowing about BUR is one thing; consistently achieving it is another. The right machinery makes a world of difference. Let's see how our BagMec® equipment can support your efforts.

BagMec® machines help master BUR through precision-engineered dies for uniform melt flow, advanced cooling systems for bubble stability, "Smart Tension Control" for consistent film feeding, and intuitive PLC controls for accurate parameter adjustment, enabling optimal film quality.

At BagMec®, we focus on designing machines that give you the control and stability needed to work effectively with various materials and BUR settings.

Precision Engineering for Stable Operations

Stable bubble formation is foundational to achieving and maintaining your target BUR.

- Optimized Die Design: Our dies are engineered for uniform melt distribution and flow. This minimizes variations that could lead to an unstable bubble, especially when pushing BUR limits or working with sensitive materials like PLA.

- Advanced Cooling Systems: We incorporate high-efficiency air rings, and for some models, Internal Bubble Cooling (IBC). This rapid and even cooling is vital for:

- Maintaining bubble stability at higher BURs.

- Processing heat-sensitive materials without degradation.

- Achieving higher output rates.

For example, our Wicketer Bread Bag Machine, which handles delicate films at speed, benefits greatly from precise cooling.

Intelligent Control and Automation

Modern film production demands precision that goes beyond manual adjustments.

- "Smart Tension Control": This patented BagMec® technology is a game-changer. It automatically maintains consistent tension on the film as it's being pulled. Stable tension is crucial because fluctuations can disturb the bubble, affect the draw-down ratio, and make it very difficult to maintain a consistent BUR and film thickness.

- PLC and Touchscreen Interfaces: Our machines feature user-friendly PLC systems with touchscreen controls. Operators can:

- Precisely set and monitor parameters like screw speeds, temperature zones, air flow, and take-up speed.

- Save recipes for different materials and BUR targets, ensuring repeatability.

- Receive real-time feedback on process conditions.

This level of control is essential when fine-tuning BUR for specific applications, like those produced on our FFS Bag Machines or Diaper Bag Making Machines.

Material Versatility and Support

We understand that our customers work with a wide array of polymers.

- Designed for Diverse Materials: Our extruders, screws, and dies are built to handle everything from standard LDPE/HDPE/LLDPE to more specialized materials like biodegradable PLA and PBAT. This includes consideration for their different melt strengths and processing windows, which directly impacts BUR capabilities.

- Expert Consultation: We do more than just sell machines. Our team provides technical support and consultation. If you're aiming for a specific BUR to achieve certain film properties for your courier bags or food packaging, we can help you configure the machine and optimize process parameters. Our experience with clients like the German packaging supplier (FFS machines) and the US eco-brand (PLA film machines) informs our advice.

By investing in robust and intelligently designed machinery, you gain better control over the BUR, leading to higher quality film, less waste, and improved operational efficiency.

Conclusion

Mastering the blow-up ratio is key for ideal film properties like strength and clarity. Material type, machine settings, and application needs all matter. BagMec® provides advanced machinery and expertise to help you achieve consistent, high-quality film production.

-

Understanding BUR is crucial for optimizing film properties and ensuring quality production. Explore this link for in-depth insights. ↩

-

Molecular orientation plays a key role in determining film strength and clarity. Discover more about its impact on film quality. ↩

-

Die gap size is a critical factor in film production that influences thickness and quality. Learn more about its importance here. ↩