Are you dealing with inconsistent film quality? This issue wastes materials and reduces the strength of your final bags. The problem often starts with a mismatch between your blow-up ratio1 and cooling system.

The blow-up ratio (BUR) determines the size of the film bubble. The cooling air ring must deliver a uniform airflow perfectly matched to this size. A higher BUR needs a more powerful and precise cooling ring to solidify the film without defects.

This relationship is a delicate balancing act. The blow-up ratio is the ratio between the final bubble diameter and the die diameter. When you increase the BUR, you are stretching the plastic film wider. This stretched film is thinner and hotter, so it needs more cooling to become stable. The cooling air ring2 provides a 360-degree curtain of air to cool and solidify the bubble. If the airflow is too weak or uneven for the bubble's size, you will get unstable production and poor-quality film.

We build our machines with this principle in mind. For a film to be strong and consistent, the polymer molecules must be "frozen" in their stretched state correctly. An undersized or poorly designed air ring can't keep up with a high BUR. This failure leads to problems like gauge bands, which are thick and thin spots in your film. These spots create weak points in the final bags, which is something we help our clients avoid through precise engineering.

How does an incorrect air ring setup affect film quality?

A poorly matched cooling system can ruin an entire production run. Let’s look at the specific problems you might see.

An incorrect air ring setup directly causes major film defects. You will see gauge variation3s, film instability, and poor optical properties like haze. This leads to weak bags that fail quality control and waste expensive raw materials.

When we talk to customers, we often trace their quality issues back to the cooling process. An air ring that isn't right for the job creates a chain reaction of problems. It’s not just about making a bag; it’s about making a bag that meets specifications every single time. Here are the issues we see most often.

Gauge Variation and Film Strength

Gauge variation means the film has inconsistent thickness. If the air ring provides uneven airflow, some parts of the bubble cool faster than others. This creates thick and thin bands around the film's circumference. Thin spots are weak points where bags can easily tear or puncture. Thick spots can cause problems with sealing and printing. Our 5-stage inspection protocol, including laser calibration, ensures our machines deliver consistent film gauge.

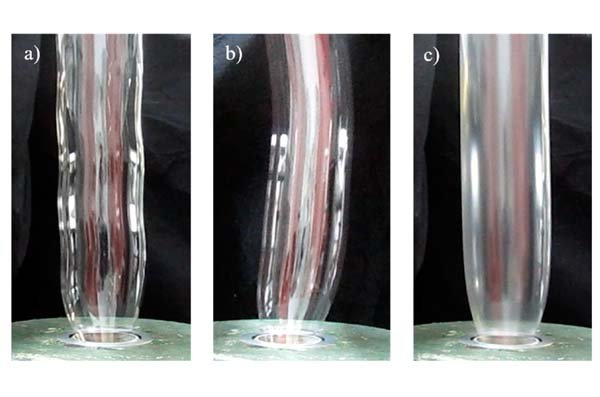

Bubble Instability

Bubble instability is when the film bubble flutters, sways, or breathes. This is a clear sign that the cooling air is not supporting the bubble correctly. It might be because the air volume is too low for the BUR, or the airflow itself is turbulent. Instability leads to wrinkles, poor roll geometry, and inconsistent film width. Our machines with "Smart Tension Control" work alongside a stable cooling system to prevent this.

Poor Optical Properties

The speed and uniformity of cooling also affect the film's appearance.

- Haze: If the film cools too slowly, the polymer crystals grow too large, making the film cloudy or hazy.

- Gloss: Rapid, uniform cooling, often achieved with our dual-lip air rings, creates a smoother surface with higher gloss.

This table shows the direct link between air ring problems and final product quality.

| Issue with Air Ring Setup | Resulting Film Defect | Impact on Bag Making |

|---|---|---|

| Uneven Airflow Volume | Gauge Bands (Thick/Thin Spots) | Weak Seals, Prone to Tearing |

| Insufficient Air Volume | Bubble Flutter / Instability | Wrinkles, Inconsistent Bag Width |

| Incorrect Air Temperature | Poor Crystallization | High Haze, Low Clarity (Gloss) |

| Turbulent Airflow | Melt Fracture / Surface Defects | Poor Print Quality, Rough Texture |

What are the different types of cooling air rings?

Choosing the right air ring is essential. Your decision should depend on your material, production speed, and quality requirements.

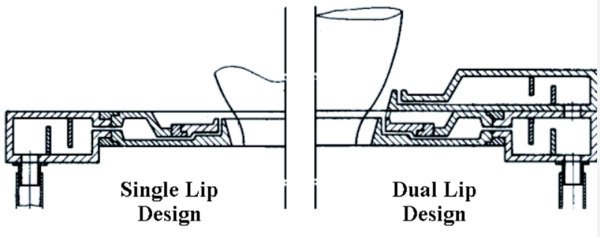

The main types are single-lip and dual-lip air rings. Single-lip rings are simple and effective for many standard applications. Dual-lip rings provide better bubble stability and cooling, making them ideal for high-speed lines and sensitive materials.

We equip our machines based on the customer's specific needs. A T-Shirt Bag Making Machine might have different cooling requirements than a Lamination Pouch Making Machine. Understanding the technology helps you make a better investment.

Single-Lip Air Rings

A single-lip air ring is the most common and straightforward design. It has one orifice, or lip, that releases a stream of cooling air.

- How it Works: It shoots air upwards along the outside of the bubble.

- Best For: General-purpose applications, especially with HDPE, where the material is naturally more stable.

- Advantages: It is a simple, reliable, and cost-effective design. Many of our entry-level machines, like the Patch Handle Bag Making Machine, may use a high-efficiency single-lip design.

Dual-Lip Air Rings

A dual-lip air ring has two separate orifices.

- How it Works: The first, lower lip directs a small amount of low-velocity air to pre-cool and stabilize the bubble right as it exits the die. The second, upper lip directs a larger volume of high-velocity air for the main cooling.

- Best For: High-speed production, high-quality films, and less stable materials like LLDPE.

- Advantages: This design dramatically improves bubble stability, allowing for higher production rates and better film quality. Our FFS bag machines and Wicketer Bread Bag Machines often use this technology to achieve high output without sacrificing quality.

Internal Bubble Cooling (IBC) Systems

This is an advanced cooling technology. In addition to the external air ring, an IBC system circulates cool air inside the bubble.

- How it Works: Fans exchange hot air inside the bubble with cool air, cooling the film from both sides.

- Best For: Very high-output lines, thick films, and large-diameter bubbles.

- Advantages: It provides the fastest cooling rates, leading to maximum throughput. This is a key feature for clients like the German packaging supplier who needs 99% uptime on demanding lines.

How do we optimize cooling for different materials?

At BagMec®, we know that every polymer behaves differently. We engineer our cooling systems to match your specific raw material.

We precisely match the air ring design and airflow controls to the material's melt properties. For LDPE, we focus on high-volume, gentle cooling. For HDPE, we use high-velocity air for stability. For PLA, we ensure precise temperature control.

Our expertise since 2017 has taught us that customization is key. Our machines are designed to be versatile and are calibrated based on the materials our customers use.

Optimizing for LDPE and LLDPE

These materials are soft and have low melt strength. They require a high volume of air to cool but can become unstable if the air velocity is too high. Our dual-lip air rings are perfect for this. The lower lip stabilizes the bubble before the high-volume cooling air from the upper lip is applied. This prevents bubble flutter and ensures a uniform film.

Optimizing for HDPE

HDPE has high melt strength and is typically extruded with a high-stalk bubble. It requires a high-velocity, stable airflow from a single-lip air ring to hold the bubble's shape and prevent it from moving. The precision of our machine components, guaranteed by our ISO 9001 certification, is critical here.

Optimizing for Biodegradable Materials (PLA)

Materials like PLA are very sensitive to temperature. If they get too hot or cool improperly, they can become brittle or degrade. For our clients like the US eco-brand, we integrate advanced PLC controls and energy-saving servo motors. This provides extremely precise and stable temperature control in the cooling process, protecting the material's integrity and ensuring the final bags are 100% compostable.

Conclusion

The blow-up ratio and the cooling air ring are deeply connected. A well-matched system is the foundation of high-quality film and strong bags. At BagMec®, we engineer our machines with this balance in mind to make your production efficient and profitable.

-

Understanding the blow-up ratio is crucial for optimizing film quality and preventing defects in production. ↩

-

Exploring the role of cooling air rings can help you enhance film stability and overall production efficiency. ↩

-

Learning about gauge variation can help you identify and solve quality issues in your film production process. ↩